+86 180 0293 5268

+86 180 0293 5268

In the realm of modern manufacturing, the precision and quality of CNC machining parts have become critical factors for achieving optimal performance in various applications. According to industry expert Dr. Emily Carter, a renowned figure in the field of precision engineering, "The quality of Precision CNC Machining Parts directly influences the efficacy and durability of the final product." This assertion underscores the importance of selecting the right components to ensure seamless operation in both intricate machinery and everyday devices.

With advancements in technology, the landscape of Precision CNC Machining Parts has evolved dramatically. Manufacturers are now capable of producing components that not only meet stringent tolerances but also enhance the overall functionality of systems. As we delve into the top 10 precision CNC machining parts, it becomes clear that understanding the intricacies of these components is essential for engineers and designers striving for excellence in their projects. Each part plays a pivotal role, and recognizing their best applications allows businesses to optimize their production processes and improve end-user satisfaction significantly.

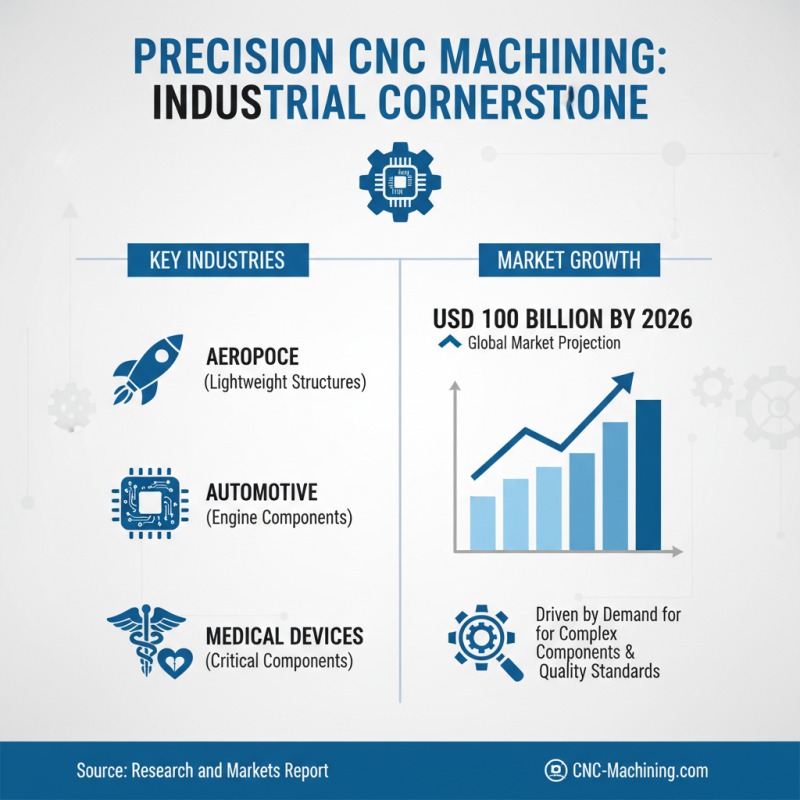

Precision CNC machining plays a critical role in modern manufacturing, delivering high-quality components with exceptional tolerances. The process relies on computer-controlled machines to produce complex parts from various materials, offering precise dimensions and surface finishes that manual machining cannot achieve. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach $100 billion by 2026, driven by increased automation and the demand for high-quality production across various industries, including aerospace, automotive, and electronics.

The significance of precision CNC machining lies in its ability to cater to intricate designs while maintaining consistency and reliability. A study by Technavio highlights that the accuracy of CNC machining can reach tolerances as tight as ±0.001 inches, making it indispensable for components where performance is critical. This precision not only enhances product reliability but also minimizes waste, thereby reducing overall production costs. As industries continue to optimize their processes for efficiency and quality, the demand for precision CNC machining solutions will likely grow, underscoring its importance in achieving optimal performance standards.

When considering the quality of CNC machined parts, several key factors come into play that can significantly influence performance and reliability. One of the most critical factors is the precision of the CNC machine itself. According to a report from the Association for Manufacturing Technology, machines with higher accuracy ratings can produce parts with tolerances as tight as ±0.001 inches. This precision is crucial, especially in industries such as aerospace and medical devices, where even the slightest deviation can lead to failures or malfunctions.

Another essential factor is the choice of material. Different materials offer varying properties that can affect the final product's performance. For instance, aluminum is often chosen for its lightweight and strength, making it ideal for applications that require high durability without excessive weight. A survey by the American Machinist indicates that around 60% of companies prefer aluminum for precision parts due to its excellent machinability and resistance to corrosion. However, the selection of the right material must be accompanied by appropriate machining techniques, as improper handling can lead to defects and compromised quality.

Lastly, the environmental conditions under which machining is performed can greatly affect the end product. Factors such as temperature, humidity, and even the cleanliness of the workspace can contribute to the precision and quality of the machined parts. A study published in the International Journal of Advanced Manufacturing Technology highlighted that control of these environmental factors can reduce part rejection rates by up to 15%. Ensuring that these variables are monitored and regulated is essential for achieving optimal machining results.

In the realm of precision CNC machining, selecting the right materials is crucial for ensuring optimal performance and quality of the finished parts. Commonly used materials include aluminum, steel, titanium, and plastics, each offering distinct advantages. For instance, aluminum is known for its lightweight nature and excellent machinability, making it a top choice for various applications, particularly in the aerospace and automotive industries. According to a recent industry report, aluminum components account for approximately 30% of the CNC machining market due to their beneficial properties.

Steel, particularly stainless steel, is equally significant, prized for its strength and durability. It is utilized in precision parts where corrosion resistance and structural integrity are paramount. Reports indicate that the use of stainless steel in CNC machining has increased by 15% in recent years, reflecting its growing demand. Titanium, while more expensive, provides exceptional strength-to-weight ratios, making it ideal for high-performance applications, like medical devices and aerospace components. The choice of plastics, such as nylon and polycarbonate, is also noteworthy, especially in industries that require lightweight and chemically resistant materials.

Tips: When selecting CNC machining materials, consider the specific application requirements such as weight, strength, and environmental exposure. Additionally, sourcing materials from reliable suppliers can significantly impact the machining process and the quality of the final product. Always review the latest industry reports for insights into emerging trends and material innovations.

This bar chart illustrates the top 10 materials used in precision CNC machining parts, showcasing their relative usage percentage to highlight their importance in achieving optimal performance and quality.

CNC machining has become a cornerstone in manufacturing due to its ability to produce parts with high precision and repeatability. Essential techniques in CNC machining play a vital role in enhancing performance and ensuring quality across various applications. According to a recent report by Industry Research, the global CNC machining market is expected to reach USD 79.41 billion by 2026, driven largely by innovations in machining techniques and automation technologies. Key methods such as multi-axis machining, which allows for complex geometries with fewer setups, have proven to significantly reduce operational time and increase productivity.

Another critical technique is the application of adaptive control during machining processes. This method involves real-time adjustments based on feedback from the machining environment, which helps maintain optimal cutting conditions and prolongs tool life. A study published in the Journal of Manufacturing Science and Engineering indicates that implementing adaptive control can lead to reductions in machining time by up to 25% while improving surface finish quality. Additionally, CNC programming strategies such as high-speed machining (HSM) enable manufacturers to achieve faster feed rates and improved material removal rates, effectively elevating the overall efficiency of production lines. These essential techniques not only bolster performance but also enhance the quality of machined components, making them indispensable in modern manufacturing.

Precision CNC machining has become a cornerstone in various industries, ensuring that components meet strict performance and quality standards. Industries such as aerospace, automotive, electronics, and medical device manufacturing heavily rely on precision CNC parts for their critical operations. According to a report by Research and Markets, the global CNC machining market is projected to reach USD 100 billion by 2026, driven by the rising demand for complex components in these sectors. Aerospace companies utilize CNC parts for lightweight structural elements, while the automotive industry leverages them for producing intricate engine components, which not only enhance efficiency but also meet stringent safety regulations.

In electronics, manufacturers need precision parts for the assembly of microelectronics, where even minute discrepancies can lead to product failure. Medical device companies are also benefiting as they require precision components for surgical instruments and implants, where the margin for error is virtually nonexistent. A recent survey from Statista indicated that 67% of manufacturers see great value in CNC machining for reducing production time and improving accuracy.

Tips: When selecting CNC machining services, consider looking for providers that utilize advanced technologies such as 5-axis machining and automated inspection processes. Additionally, always check for certifications like ISO 9001 to ensure adherence to industry standards. Understanding the specific needs of your application can greatly influence the choice of materials and machining processes, ultimately enhancing the overall performance of your final product.