+86 180 0293 5268

+86 180 0293 5268

In recent years, the advancements in manufacturing technologies have significantly transformed various industries, and one area that stands out is the innovation in stainless steel casting parts. As a vital component in numerous applications, from automotive to aerospace, these parts are subject to stringent requirements for durability, efficiency, and design versatility.

This blog, "15 Top Stainless Steel Casting Parts Innovations You Need to Know," delves into the latest breakthroughs and trends shaping the future of stainless steel casting. We’ll explore how cutting-edge techniques and materials are enhancing the performance of these components, addressing challenges such as weight reduction and corrosion resistance. Join us as we uncover the leading innovations that are set to revolutionize the landscape of stainless steel casting parts, providing insights into what lies ahead in this dynamic field.

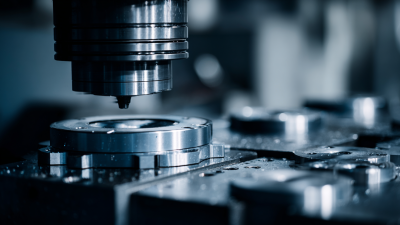

In recent years, stainless steel casting technologies have witnessed revolutionary advancements, driving efficiency and innovation across various industries. Cutting-edge techniques such as investment casting, additive manufacturing, and 3D printing have transformed the way stainless steel components are produced. These methods not only enhance the precision of complex designs but also significantly reduce waste, making the manufacturing process more sustainable. As a result, businesses are increasingly adopting these technologies to meet the growing demand for high-performance and environmentally friendly materials.

Moreover, the integration of smart technologies into stainless steel casting processes is reshaping traditional manufacturing paradigms. Automation and machine learning are now being utilized to optimize casting parameters and monitor quality in real-time. This data-driven approach ensures consistent product quality and minimizes defects, ultimately leading to reduced production costs. The ongoing research and development in this field promise even more groundbreaking innovations on the horizon, solidifying stainless steel's role as a vital material in modern engineering and manufacturing.

Stainless steel castings have become a vital component across various modern industries, offering durability, corrosion resistance, and versatility. In aerospace applications, these castings are critical for creating lightweight yet strong structures that enhance fuel efficiency and performance. The application of stainless steel castings in the aerospace sector showcases how advancements in manufacturing techniques, such as metal additive manufacturing, are pushing the boundaries of what is possible. These innovations enable the production of intricate designs that were previously unattainable, allowing for improved functionality and reduced weight.

In the automotive industry, stainless steel castings play a crucial role in components like exhaust systems, engine blocks, and transmission casings. Their resistance to heat and corrosion ensures longevity and reliability under challenging conditions. The adoption of rapid investment casting processes, including 3D printing technologies, has transformed manufacturing capabilities, permitting faster production times and reduced material waste. As industries continue to embrace these innovations, the application of stainless steel castings will undoubtedly expand, leading to more efficient and sustainable practices across various sectors.

Innovative techniques for enhancing the durability of cast stainless steel parts are shaping the future of manufacturing. Recent studies indicate that advancements like advanced heat treatment processes can significantly improve the mechanical properties of stainless steel castings. For example, research published in the Journal of Materials Science highlights that utilizing methods such as proprietary heat treatment can enhance tensile strength by up to 30%, offering a robust solution for industries that demand high-performance components.

Another significant innovation is the use of alloying elements and novel casting technologies. Incorporating elements like nitrogen and chromium during the casting process has been shown to improve corrosion resistance while maintaining structural integrity. A report from the International Journal of Metalcasting demonstrated that cast stainless steel parts treated with these alloying techniques exhibited a 20% increase in hardness compared to traditional methods, indicating a promising approach for parts exposed to harsh environments. As these innovations continue to evolve, industries can expect longer-lasting, more reliable stainless steel components that meet stringent operational demands.

Additive manufacturing, commonly known as 3D printing, is revolutionizing the stainless steel casting industry by enhancing design flexibility and production efficiency. According to a report by the Wohlers Associates, the additive manufacturing market is projected to grow from approximately $12.6 billion in 2020 to $35.6 billion by 2024, indicating a robust interest in technologies that complement traditional manufacturing processes. Particularly in stainless steel casting, additive manufacturing allows for the creation of complex geometries and lightweight structures that are not feasible with conventional methods. This advancement not only reduces material waste but also significantly shortens the lead time for tooling and production.

Moreover, the integration of additive manufacturing in stainless steel casting presents significant cost savings. The McKinsey Global Institute report highlights that transformative manufacturing technologies such as 3D printing could lower production costs by 50% and lead to a 30% reduction in development times. Such efficiencies are vital as industries transition toward more sustainable practices. As companies explore these innovations, they stand to gain a competitive edge in producing high-quality, custom stainless steel components that meet the evolving demands of various sectors, including aerospace and automotive.

When embarking on a stainless steel casting project, selecting the right grade of stainless steel is crucial for achieving the desired properties and performance. Factors such as corrosion resistance, strength, and thermal conductivity should be taken into account. For instance, austenitic stainless steels, such as 304 and 316, are widely used due to their excellent corrosion resistance and formability. However, if enhanced strength and temperature resistance are required, martensitic grades like 410 could be more suitable. Understanding these specifications can significantly impact the longevity and durability of the final product.

Additionally, it's essential to consider the casting process itself when choosing stainless steel. Different casting techniques, such as investment casting or sand casting, can affect the performance characteristics of the material. For example, investment casting allows for closer tolerances and finer details, making it a preferred choice for complex geometries. Furthermore, keeping in mind the end application of the casting will ensure that the selected stainless steel not only meets mechanical requirements but also aligns with environmental conditions. Therefore, a thoughtful selection process tailored to your specific needs will pave the way for successful stainless steel casting projects.

| Innovation | Description | Benefits | Applications |

|---|---|---|---|

| 3D Printing Technology | Utilization of 3D printing for creating complex stainless steel parts. | Enhanced design flexibility and reduced lead times. | Aerospace, Medical Equipment, Automotive. |

| Investment Casting | A precision casting process using a wax model. | High accuracy and superior surface finish. | Industrial Parts, Machinery Components. |

| Vacuum Casting | Casting under a vacuum to reduce contamination. | Improved integrity of cast parts and reduced defects. | Precision Engineering, Specialty Applications. |

| Die Casting | Process that forces molten metal into a mold. | High-volume production and consistent quality. | Consumer Goods, Electronics. |

| Centrifugal Casting | Using centrifugal force to distribute metal in a mold. | Improved density and strength of cast components. | Pipelines, Rotating Components. |

| Sand Casting | Creating a mold from sand for casting. | Cost-effective and versatile for large parts. | Construction, Automotive Parts. |

| Shell Molding | Using a thin shell of sand for casting molds. | Greater accuracy and smoother surfaces. | Heavy Machinery, Aerospace. |

| Low Pressure Casting | Using low pressure to fill molds. | Less metal wastage and excellent fill rates. | Automobile Components, Electronics Housings. |

| Lost Foam Casting | Replacing foam patterns with molten metal. | Complex geometries possible without cores. | Automotive, Industrial Applications. |

| Metal Injection Molding | Injecting metal powders into molds. | High production rates and intricate shapes. | Medical Devices, Consumer Products. |

| Hybrid Casting Techniques | Combining traditional methods with modern technologies. | Optimization of both processes for better outcomes. | Manufacturing, Heavy Machinery. |

| Electroforming | Electrochemical process to create objects. | High precision and customization. | Jewelry, Fine Arts, Medical Applications. |

| Customized Alloys | Developing unique stainless steel alloys for specific uses. | Improved performance and durability in targeted applications. | Specialty Tools, Marine Industries. |

| Rapid Prototyping | Quickly developing prototypes for testing designs. | Faster time to market for new products. | Product Development, Automotive. |