+86 180 0293 5268

+86 180 0293 5268

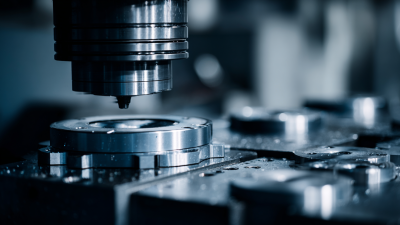

In the ever-evolving landscape of Metal Parts Manufacturing, sourcing high-quality components is crucial for ensuring operational efficiency and product reliability. According to a recent report by Mordor Intelligence, the global metal fabrication market is expected to reach $23 billion by 2026, driven by advancements in manufacturing technologies and increasing demand across various industries, including automotive and aerospace. However, the challenge remains in identifying suppliers that consistently meet stringent quality standards while offering competitive pricing.

With over 50% of manufacturers reporting quality issues with sourced components, implementing effective sourcing strategies is more important than ever. This tutorial will explore several top strategies for identifying and securing high-quality metal parts that meet your manufacturing needs, ensuring your production processes remain seamless and efficient.

Sourcing high quality metal parts for manufacturing can be fraught with challenges that impact production efficiency and product quality. One of the most common challenges is the lack of standardization in part specifications across different suppliers. According to a report by the International Organization for Standardization (ISO), up to 30% of manufacturing errors are attributed to component mismatch or substandard quality from suppliers. This highlights the importance of clearly defining specifications and ensuring all suppliers adhere to industry standards to mitigate risks and ensure compatibility.

Another significant challenge is supply chain disruptions, which have been exacerbated by recent global events. A survey conducted by the Institute for Supply Management (ISM) revealed that 75% of manufacturing firms reported supply chain interruptions, leading to increased lead times and costs. Manufacturers must diversify their supplier base and consider local sourcing options to reduce dependency on single sources. Implementing robust risk management strategies, such as dual sourcing and maintaining safety stock levels, can help mitigate these challenges and ensure a steady supply of high-quality metal parts necessary for maintaining competitive advantage in the industry.

When sourcing high-quality metal components, understanding material specifications is crucial to ensuring the durability and performance of your final product. Different metals possess unique characteristics that affect their suitability for various manufacturing applications.

For instance, stainless steel is often favored for its corrosion resistance and strength, making it ideal for components exposed to harsh environments. On the other hand, aluminum is lightweight and versatile, perfect for applications requiring reduced weight without sacrificing strength.

For instance, stainless steel is often favored for its corrosion resistance and strength, making it ideal for components exposed to harsh environments. On the other hand, aluminum is lightweight and versatile, perfect for applications requiring reduced weight without sacrificing strength.

Tip: Always request detailed material specifications from suppliers, focusing on factors such as tensile strength, hardness, and thermal conductivity. This information will help you make informed decisions and select the best metal that meets your project requirements.

Additionally, consider the manufacturing processes when evaluating material specifications. Processes like machining, welding, or forging can influence the overall quality of the metal part. By understanding how different materials react to specific manufacturing methods, you can optimize your design for both efficiency and performance.

Tip: Engage with your suppliers early in the design process to discuss material options and manufacturing capabilities. Maintaining open communication can lead to valuable insights and enhance the quality of the components you produce.

When sourcing high-quality metal parts for manufacturing, evaluating supplier capabilities and quality assurance processes is crucial. A report by the International Organization for Standardization (ISO) indicates that organizations with strong quality management systems can improve their productivity by up to 20%. This highlights the importance of selecting suppliers who adhere to ISO 9001 standards and demonstrate robust quality control measures. Suppliers should be able to display certifications and provide evidence of their capability to consistently meet specifications.

In addition to certifications, businesses should assess the supplier's technological capabilities. A study from the American Society for Quality (ASQ) notes that advanced machining technologies can enhance precision and reduce defects by up to 30%. Therefore, it's essential to evaluate whether potential suppliers utilize state-of-the-art manufacturing techniques and equipment. Furthermore, suppliers should have clearly defined quality assurance processes, such as regular inspections and testing protocols, to ensure that every part meets the required standards before shipment.

By prioritizing these evaluation criteria, manufacturers can mitigate risks and secure high-quality components for their production lines.

In the ever-evolving landscape of manufacturing, sourcing high-quality metal parts has become a paramount concern for companies striving to maintain efficiency and competitiveness. Leveraging industry standards can significantly enhance sourcing efficiency, particularly in a time when sustainable practices are gaining traction. Establishing clear benchmarks rooted in recognized industry standards can guide manufacturers in selecting suppliers who not only meet quality needs but also adhere to environmental and social governance (ESG) principles. This alignment is crucial as companies face increasing pressures to demonstrate their commitment to sustainability while ensuring supply chain resilience.

Furthermore, the integration of advanced technologies within the sourcing process allows manufacturers to refine their approach to sourcing metal parts. By adopting digital tools and platforms, companies can gain real-time insights into market conditions, enabling them to make informed decisions that align with industry standards. This strategic approach not only mitigates risks associated with supply chain disruptions but also positions manufacturers to seize new opportunities arising from changes in the global economic landscape, such as shifts towards greener production methods. Overall, the emphasis on leveraging industry standards paints a compelling picture of sourcing that is not only effective but also responsible in the context of modern manufacturing challenges.

In today’s manufacturing landscape, leveraging technology and data analytics is paramount for sourcing high-quality metal parts. A recent report by McKinsey & Company underscores that organizations that use advanced data analytics can reduce sourcing costs by up to 20%. This is achieved by utilizing predictive analytics to identify the best suppliers and optimizing inventory management based on real-time market trends.

Moreover, integrating cloud-based platforms enhances collaboration and facilitates better access to supplier performance metrics, ensuring that manufacturers can make informed sourcing decisions.

Another study published in the Journal of Manufacturing Science and Engineering reveals that companies embracing automated sourcing processes experience a 40% improvement in lead times. Utilizing technologies such as AI and machine learning, manufacturers can analyze vast amounts of supplier data to identify potential risks and opportunities more efficiently. By prioritizing data-driven sourcing strategies, businesses can not only enhance the quality of their metal parts but also build resilient supply chains that adapt swiftly to market changes.

Embracing these technological advancements is no longer optional; it is essential for staying competitive in the evolving manufacturing sector.