+86 180 0293 5268

+86 180 0293 5268

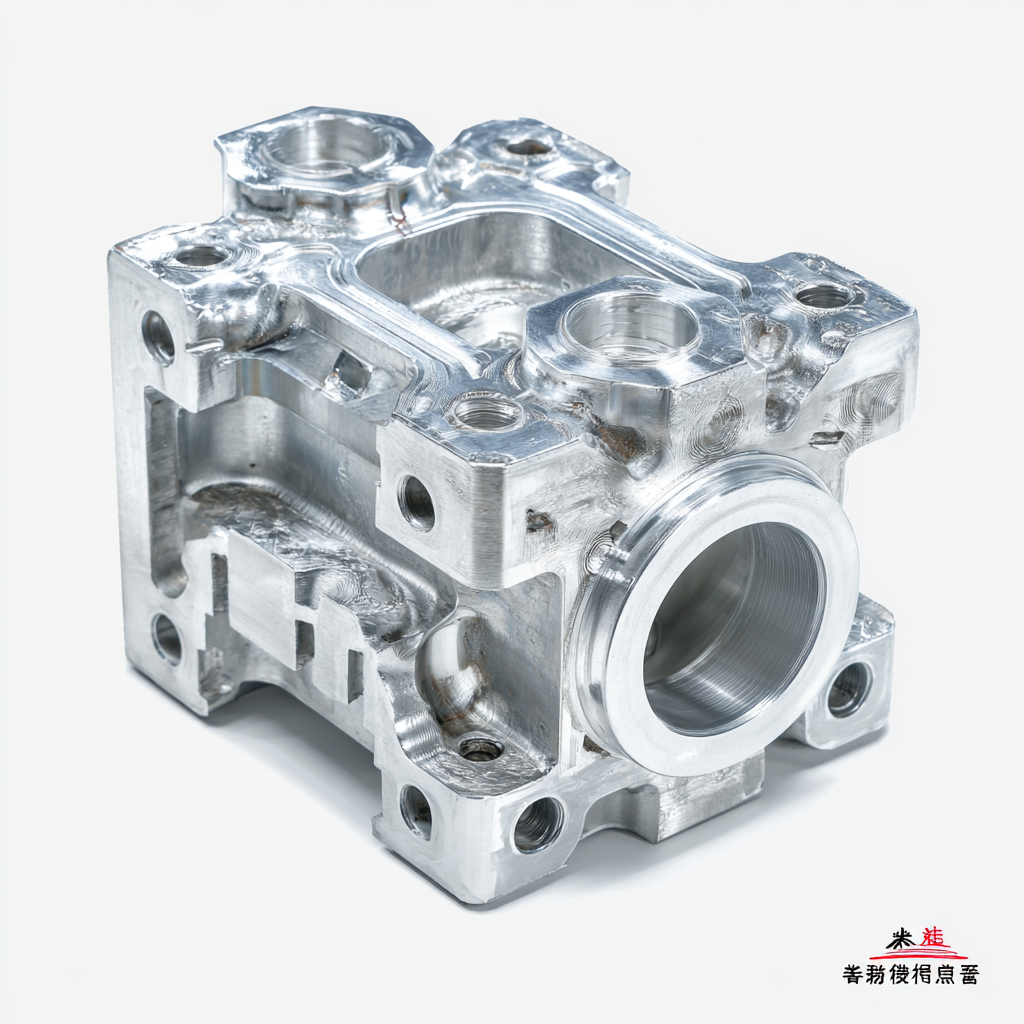

The global demand for high-quality aluminum components continues to soar, driven by rapid advancements in various industries such as automotive, aerospace, and electronics. A pivotal solution embracing this demand is Wax Casting Aluminum, a technique renowned for its precision and ability to create intricate designs. According to a recent industry report by ResearchAndMarkets, the wax casting market is poised to grow at a CAGR of over 8% from 2021 to 2026, highlighting its increasing adoption among manufacturers seeking superior quality and reduced production costs. With China emerging as a powerhouse in aluminum manufacturing, renowned for its commitment to quality and innovation, products made through Wax Casting Aluminum are gaining traction globally. As we delve deeper into the advantages of this method, we'll explore how it not only meets but exceeds the expectations of international buyers seeking efficiency and excellence in their components.

In the ever-evolving landscape of aluminum production, alternative wax casting techniques have emerged as a cost-effective solution for global buyers looking to optimize their manufacturing processes. According to a recent industry report by MarketsandMarkets, the global investment castings market is projected to reach $25.5 billion by 2026, with a significant shift towards innovative casting methods, including wax casting. This growth is largely fueled by the demand for precision and reduced material wastage, essential for enhancing profitability in production.

One key advantage of alternative wax casting techniques lies in their ability to produce complex geometries with minimal finishing requirements. A study by Research and Markets highlights that these advanced processes can reduce lead times by up to 30%, allowing manufacturers to respond quickly to market demands. Furthermore, the use of recycled wax in these techniques not only mitigates environmental impact but also lowers material costs, making it a favorable option for aluminum foundries aiming to improve their bottom line while maintaining sustainability practices.

| Technique | Cost Per Unit ($) | Production Time (Hours) | Material Waste (%) | Surface Finish Quality |

|---|---|---|---|---|

| Traditional Wax Casting | 5.00 | 10 | 12 | High |

| E-Wax Technology | 4.50 | 8 | 8 | Very High |

| Castable 3D Printing | 6.00 | 12 | 15 | Medium |

| Shell Molding | 4.00 | 6 | 10 | High |

| Investment Casting | 5.50 | 10 | 9 | Very High |

Wax casting aluminum has emerged as a frontrunner in the global markets, particularly when compared to traditional casting methods. Unlike conventional techniques that can be time-consuming and resource-intensive, wax casting simplifies the process by allowing for more intricate designs and faster turnaround times. This method utilizes a wax pattern that can be melted away, resulting in a precise aluminum casting that meets the exact specifications of the buyer.

Furthermore, the reduced material waste associated with wax casting makes it a more sustainable option, appealing to environmentally conscious companies.

When considering the switch from traditional methods to wax casting, buyers should keep a few key tips in mind. First, it is essential to evaluate the level of detail required for your projects, as wax casting excels in producing complex geometries that traditional methods may struggle to achieve. Second, always consult with reputable suppliers who understand the nuances of alloy selection and the impact on final product performance. Lastly, don't overlook the advantages of faster production times, which can significantly enhance supply chain efficiency, especially for high-volume orders.

In the competitive global market, embracing innovations like wax casting aluminum can provide distinct advantages, particularly in terms of cost-effectiveness and design flexibility. As manufacturers aim to meet the demands of various industries, those who adapt to these efficient methods may find themselves at a significant advantage over competitors still reliant on traditional casting techniques.

Innovative wax casting alternatives in aluminum have become a focal point for manufacturers aiming to enhance product quality. According to a report by Market Research Future, the global aluminum die casting market is predicted to reach $33 billion by 2025, driven in part by advancements in casting technologies. Wax casting methods enable intricate designs and smoother finishes, resulting in improved mechanical properties and reduced post-processing requirements. The precision achieved with wax casting allows for tighter tolerances, which is essential in industries where reliability and durability are paramount.

Furthermore, recent studies indicate that wax casting can significantly lower production costs. A report from Grand View Research suggests that using advanced casting techniques can lead to a reduction in scrap rates by up to 30%, making the process not only more environmentally friendly but also more economically viable. The transition to high-performance wax casting is not merely a trend; it is a strategic move for global buyers looking to remain competitive by leveraging technology that enhances overall product integrity and production efficiency.

In recent years, the importance of sustainability has permeated various industries, and the wax casting aluminum sector is no exception. Eco-friendly practices have become pivotal for manufacturers aiming to meet the demands of environmentally conscious global buyers. By leveraging recycled aluminum, companies can significantly reduce their carbon footprint while providing high-quality casting solutions. This not only conserves natural resources but also minimizes energy consumption during production, aligning with the growing emphasis on sustainable manufacturing.

Moreover, adopting innovative techniques in the wax casting process plays a crucial role in enhancing sustainability. For instance, utilizing water-soluble waxes and biodegradable materials can decrease harmful emissions and waste associated with traditional casting methods. As more companies implement these green practices, they not only contribute to a healthier planet but also attract discerning buyers who prioritize sustainability in their purchasing decisions. By staying committed to eco-friendly initiatives, wax casting aluminum manufacturers are positioning themselves as leaders in a rapidly evolving market focused on both quality and environmental responsibility.

The global aluminum casting market is poised for significant growth, fueled by the increasing demand for lightweight materials across various industries. With a projected value of USD 125.7 billion by 2031, the sector is experiencing a compound annual growth rate (CAGR) of 7.5%. As manufacturers look to innovate and enhance their offerings, the adoption of advanced techniques such as wax casting is becoming pivotal. This method not only improves the precision of aluminum parts but also caters to the rising demand for high-performance components in automotive and aerospace applications.

Emerging trends in the industry highlight a shift towards sustainable practices, with manufacturers exploring alternatives to traditional casting methods. The impact of global trade policies, specifically tariff disruptions, is also influencing aluminum prices and market dynamics. As companies adapt to these changes, they are increasingly focusing on integrating technology and efficiency into their production processes. This evolution in casting techniques presents a unique opportunity for global buyers to access superior aluminum products that meet modern performance standards while aligning with sustainable practices in a competitive market.