+86 180 0293 5268

+86 180 0293 5268

Investment casting metals have emerged as crucial materials in modern manufacturing, offering unparalleled versatility and precision. According to the latest market analysis by ResearchAndMarkets, the global investment casting market is projected to reach USD 26.05 billion by 2028, growing at a CAGR of 5.1% from 2020. This growth is fueled by the increasing demand for high-performance components across various industries, including aerospace, automotive, and industrial machinery.

Investment casting metals have emerged as crucial materials in modern manufacturing, offering unparalleled versatility and precision. According to the latest market analysis by ResearchAndMarkets, the global investment casting market is projected to reach USD 26.05 billion by 2028, growing at a CAGR of 5.1% from 2020. This growth is fueled by the increasing demand for high-performance components across various industries, including aerospace, automotive, and industrial machinery.

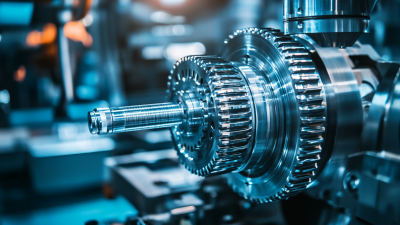

Investment casting allows for the production of complex geometries and intricate designs with minimal waste and superior surface finish, making it an attractive option for manufacturers looking to enhance efficiency and sustainability. As industries continue to evolve, understanding the properties and applications of investment casting metals becomes essential for harnessing their full potential in advanced manufacturing processes.

Investment casting, often referred to as lost-wax casting, is a time-honored method that plays a crucial role in modern manufacturing. This technique involves creating a precise wax pattern that is coated with a ceramic shell. Once heated, the wax melts away, leaving behind a mold that is then filled with molten metal. This process allows for intricate designs and high-precision components, making it particularly valuable for industries that require detailed and complex parts, such as aerospace, automotive, and medical manufacturing.

One of the primary advantages of investment casting is its versatility in materials. Various metals, including stainless steel, aluminum, and brass, can be employed, enabling manufacturers to meet specific requirements for strength, weight, and corrosion resistance. Moreover, investment casting can achieve near-net shape components, reducing the need for extensive machining and minimizing material wastage.

This efficiency not only lowers production costs but also supports sustainable manufacturing practices, making investment casting a key process in the contemporary industrial landscape.

Investment casting, renowned for its precision and versatility, enables manufacturers to effectively utilize a variety of metals, each offering distinct advantages. Recent trends highlight the growing interest in innovative metal casting techniques among educational institutions and industry practitioners. For example, students at New Mexico State University are engaging in hands-on projects that merge art and engineering, utilizing metal castings to create public artworks that reflect both creativity and skill. This initiative not only fosters artistic expression but also emphasizes the practical applications of different metals in investment casting.

The dynamic global metal casting market is projected to reach USD 325.69 billion by 2033, displaying significant growth driven by the increasing adoption of diverse metals in manufacturing processes. The versatility of metals such as aluminum, zinc, and specialty alloys in investment casting enables the production of intricate designs with high dimensional accuracy. As manufacturing technologies evolve, including advancements in additive manufacturing, the potential for complex geometries and rapid prototyping continues to expand. This shift underscores the importance of understanding the unique properties of various metals, paving the way for enhanced product performance across multiple industries.

Investment casting, also known as lost-wax casting, has become a pivotal manufacturing process in various industries due to its ability to create highly intricate and precise metal components. In aerospace, for example, investment cast metals are utilized to produce turbine blades and other critical components that demand high performance and durability under extreme conditions. The process allows for the creation of lightweight yet strong parts, contributing to fuel efficiency and overall aircraft performance.

Investment casting, also known as lost-wax casting, has become a pivotal manufacturing process in various industries due to its ability to create highly intricate and precise metal components. In aerospace, for example, investment cast metals are utilized to produce turbine blades and other critical components that demand high performance and durability under extreme conditions. The process allows for the creation of lightweight yet strong parts, contributing to fuel efficiency and overall aircraft performance.

In the automotive sector, investment casting plays a vital role in producing components such as engine blocks, transmission housings, and intricate gear systems. The ability to create complex geometries with minimal machining reduces material waste and enhances production efficiency. Moreover, the versatility of investment cast metals extends to medical applications, where custom implants and prosthetics are crafted to meet specific patient requirements. The biocompatibility and strength of materials used in investment casting ensure that these medical devices are safe and effective for long-term use. These applications illustrate the broad range of investment casting's influence across various fields, highlighting its significance in modern manufacturing.

Investment casting has long been a critical method in modern manufacturing, praised for its ability to produce complex shapes and high precision. However, the technology faces several challenges, such as the rising costs of metals, maintaining dimensional accuracy, and ensuring consistent quality across large production runs. These issues necessitate ongoing innovation and adaptation within the industry.

One key innovation is the development of advanced ceramic materials for molds that enhance thermal stability and reduce the likelihood of defects. Additionally, integrating computer numerical control (CNC) techniques with traditional casting processes helps manufacturers achieve finer tolerances and higher repeatability.

Tip: When selecting metals for investment casting, consider not just cost, but also the material's properties such as strength, corrosion resistance, and machinability to ensure optimal performance in application.

As manufacturers continue to explore new materials and technology, it's crucial to stay updated with industry advancements and seek partnerships that foster innovation. Collaborating with research institutions can lead to breakthroughs that not only overcome current challenges but also push the boundaries of what investment casting can achieve in various sectors.

Tip: Embrace continuous learning through workshops and seminars to keep up with the latest techniques and materials in investment casting.

The future of investment casting in manufacturing is poised for significant advancements, particularly as industries adapt to evolving demands for efficiency and sustainability. With a growing emphasis on lightweight materials, especially in automotive applications, manufacturers are increasingly seeking innovative casting solutions. These advancements not only streamline production processes but also align with stringent regulatory measures aimed at reducing vehicle emissions. The shift towards high-performance alloys and tailored casting techniques will enhance the versatility of investment casting, allowing for the production of complex geometries with superior material properties.

Moreover, global market trends indicate a substantial growth trajectory for the investment casting sector. Industries are expected to expand their use of investment cast metals, particularly in the automotive, metallurgy, and machinery sectors. Regions such as Latin America and Central Asia are emerging as focal points for investments, driven by demand for high-quality components. As companies continue to invest in research and development, the incorporation of advanced technologies, such as artificial intelligence and automation, will likely transform traditional casting methods, making them more efficient and responsive to market needs. This evolution underscores the critical role of investment casting metals in enhancing manufacturing efficiency in a rapidly changing industrial landscape.