+86 180 0293 5268

+86 180 0293 5268

In recent years, the global landscape of manufacturing has been significantly transformed, with Precision Metal Machining emerging as a pivotal factor in this evolution. According to a report by MarketsandMarkets, the precision machining market is projected to reach USD 80.54 billion by 2026, growing at a CAGR of 6.1% from 2021. This growth is not only driven by advancements in technology and the increasing demand for high-quality components across various sectors, including aerospace, automotive, and medical, but also by the exceptional capabilities demonstrated by Chinese manufacturers. As China positions itself at the forefront of this industry, the country’s commitment to excellence in precision metal machining is fostering global trust and reshaping the standards of production. This blog will explore how Chinese manufacturing prowess in precision metal machining is leading the world, establishing benchmarks for quality, efficiency, and innovation.

In the rapidly evolving global metal machining markets, precision remains a pivotal element that drives both quality and competitiveness. The market for metal cutting tools, valued at approximately USD 82.24 billion in 2024, is projected to grow significantly, reaching around USD 113 billion by 2030. This surge reflects an increasing reliance on metal machining processes across various industries, particularly in response to rising infrastructure investments and technological advancements.

Moreover, the CNC metal cutting machine tools market is expected to witness remarkable growth, with projections estimating it to surpass USD 103.40 billion by 2033. This growth can be attributed to the integration of automation and smart technologies, which enhances precision in machining operations. As businesses seek to meet the exacting demands of global markets, the ability to deliver consistent, high-quality results will set the benchmark for success in the metal machining industry.

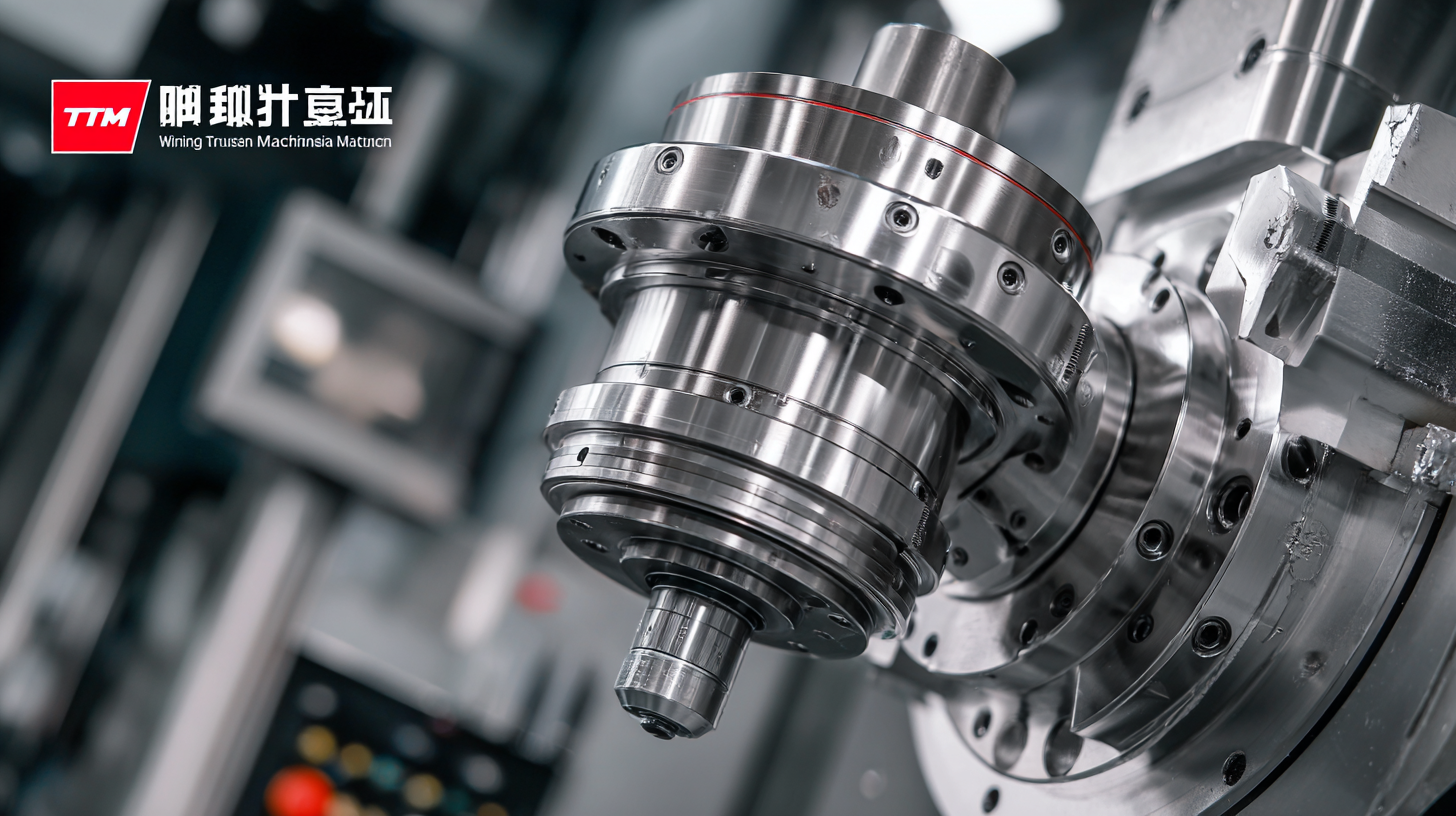

The recent CIMES 2024 exhibition in Beijing highlights the pivotal advancements in precision metal machining within China, showcasing technologies that propel the industry to new heights. With a focus on strengthening the entire industrial chain, the exhibition emphasizes the significance of high-end value chains in metal cutting and specialized equipment. Emerging technologies are not merely enhancing efficiency but also ensuring that Chinese manufacturing meets global standards of excellence.

Key technologies driving this shift include advanced machining solutions such as high-purity metal sputtering targets, crucial for the integrated circuit industry. Furthermore, innovations in metalworking fluids are playing a vital role in improving machining processes, ensuring enhanced lubrication and cooling. The confluence of these technologies is setting the stage for Chinese metal machining to gain international recognition, fostering trust in its capabilities through a commitment to quality and precision. As the sector evolves, it is clear that the fusion of traditional craftsmanship with cutting-edge technology is establishing a new benchmark for excellence on a global scale.

In the realm of precision metal machining, quality standards are paramount for ensuring excellence and maintaining global trust. Evaluating these standards requires a comprehensive understanding of the processes and technologies involved. Companies that focus on rigorous quality assessment protocols not only enhance their production efficiency but also build a reputation for reliability and precision, crucial in sustaining long-term partnerships.

Tip 1: Integrate advanced quality management systems to continuously monitor and improve machining processes. Utilizing tools such as Six Sigma or ISO 9001 can help identify inefficiencies and reduce variability, ensuring high-quality outcomes.

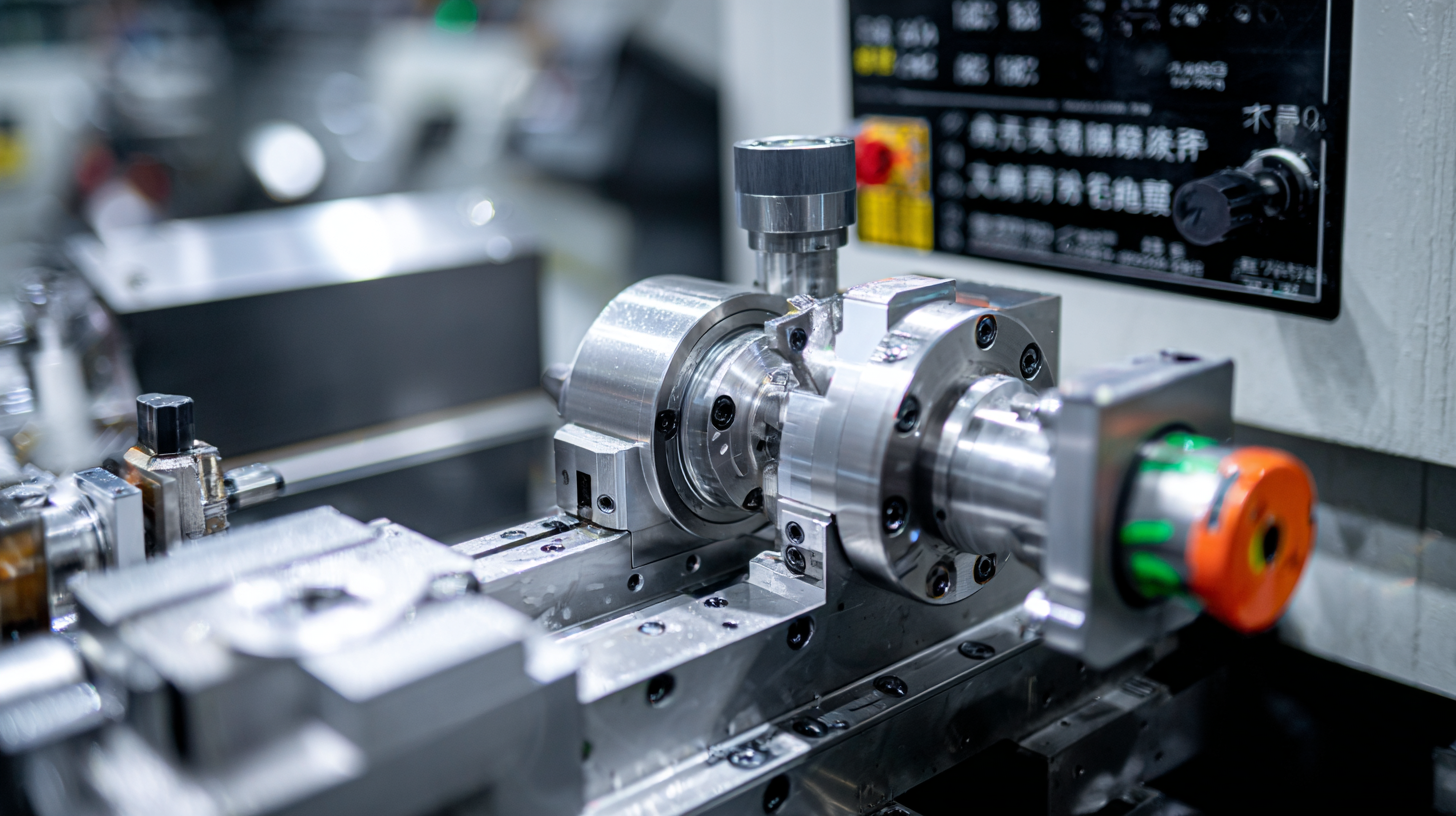

Tip 2: Invest in state-of-the-art machinery and technology. The right equipment can significantly impact the precision and quality of the final product. Regularly upgrading tools and adopting innovative machining techniques can drive excellence in manufacturing.

By implementing robust quality evaluations and leveraging modern technologies, manufacturers can cultivate a reputation for precision that resonates globally, showcasing China's commitment to excellence in metal machining.

In the realm of global manufacturing, the ability to build trust through transparency and communication is paramount. Chinese companies specializing in precision metal machining are increasingly recognizing that fostering a culture of openness not only enhances customer relationships but also boosts their reputation on the world stage. By sharing detailed processes, quality control measures, and timely updates throughout the production cycle, manufacturers can establish a level of confidence that resonates with clients worldwide. This commitment to transparency serves as a strategic advantage, showcasing not only the quality of products but also the integrity of the business practices involved.

Effective communication plays an equally critical role in this equation. By proactively engaging with stakeholders—whether they are suppliers, customers, or regulatory bodies—Chinese manufacturers can preemptively address concerns and align expectations. Utilizing modern digital tools, companies can ensure that they maintain an ongoing dialogue, facilitating smoother collaborations and quicker resolutions to any potential issues. When clients feel heard and valued, their trust in the brand solidifies, ultimately leading to long-lasting partnerships. Together, transparency and communication create a formidable foundation for excellence in manufacturing, positioning Chinese firms as leaders in precision metal machining on the global stage.

In the ever-evolving landscape of global trade, Chinese excellence in precision metal machining has emerged as a pivotal player driving success across various industries. Case studies showcasing remarkable achievements by Chinese manufacturers highlight their innovation and commitment to quality. One such example is a prominent automotive component supplier that leveraged advanced machining techniques to achieve significant reductions in production time while enhancing product reliability. By integrating cutting-edge technology and stringent quality control measures, this company not only met but exceeded international standards, securing contracts with leading global automotive brands.

Another inspiring case involves a Chinese aerospace parts manufacturer that established a reputation for exceptional precision. By investing in state-of-the-art CNC machinery and employing skilled engineers, the company was able to manufacture complex components with unparalleled accuracy. As a result, they successfully penetrated the competitive international market, supplying components to major aerospace companies. These success stories illustrate how Chinese precision machining is not merely about mass production but also about developing trust through craftsmanship and a relentless pursuit of excellence. As these companies continue to expand their global footprint, they redefine the standards of quality and dependability in the machining sector.