+86 180 0293 5268

+86 180 0293 5268

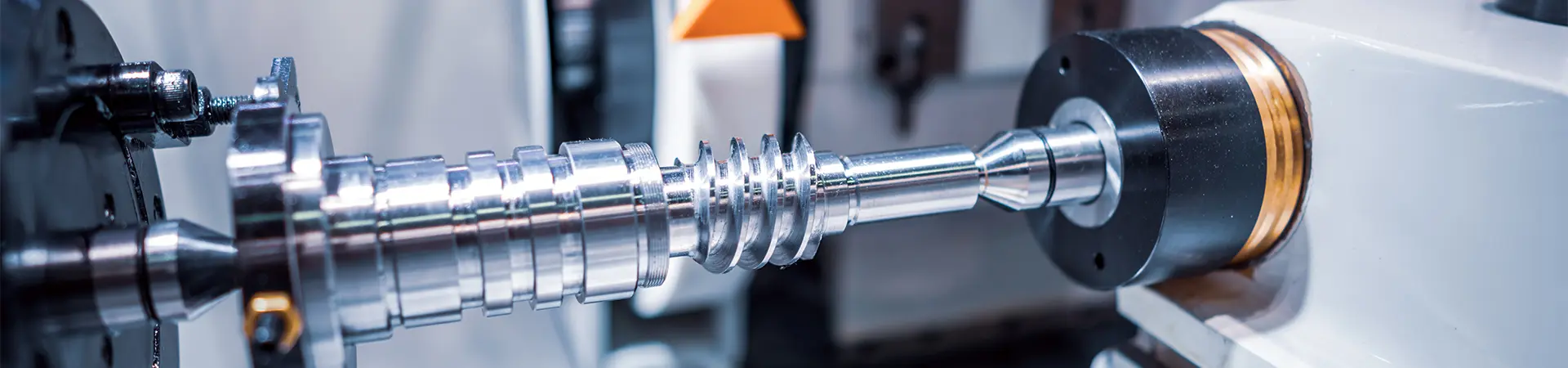

CNC Turning Titanium Alloy Screws for Mountain Bike Modification

Characteristic

Our titanium alloy turned parts and screws combine unmatched material properties with precision machining for critical applications. Titanium’s natural biocompatibility makes our components ideal for medical implants, while its high melting point (1,668°C) ensures reliability in aerospace and automotive extremes. The self-forming oxide layer provides permanent corrosion resistance, even in saltwater environments. For cycling and motorsports, our screws deliver 30% weight savings versus steel with equal tensile strength, reducing fatigue stress. CNC-turned threads achieve Class 3A fit tolerances for vibration resistance, and anodizing options enable color-coding without compromising integrity. Whether for industrial machinery or high-end consumer products, we transform titanium’s innate advantages into functionally superior components through exacting manufacturing.

Our CNC-machined titanium components redefine durability and efficiency in precision engineering. With 45% lighter weight than steel and twice the strength of aluminum, our titanium screws and turned parts optimize performance in weight-sensitive applications. The material’s fatigue resistance ensures longevity under cyclic loads, while its non-magnetic properties make it indispensable for electronics and defense. Advanced Swiss-style CNC turning enables complex micro-parts with ±0.01mm tolerances for precise assembly. Eco-conscious manufacturers benefit from titanium’s 100% recyclability, aligning with sustainable production goals. From robotics to renewable energy systems, we deliver future-proof solutions that outperform conventional metals in extreme conditions.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

Precision CNC machining services for custom titanium parts & screws—prototyping to bulk production, with strict tolerances & industry-grade finishes.

description2