+86 180 0293 5268

+86 180 0293 5268

Business Combination and Corporate Relocation.

We are pleased to announce that, to better serve our international clients and streamline the management of domestic and overseas operations, the company will relocate to a new facility starting October 2025. Additionally, we will integrate our export business with the former Shenzhen SCZY Technology Co., Ltd (hereinafter referred to as "SCZY"). Following this transition, SCZY will focus entirely on serving domestic clients and manufacturing products for the local market, while Dongguan SX Technology Co., Ltd (hereinafter referred to as "SX") will dedicate all resources to international customer service, overseas product manufacturing, and after-sales support.

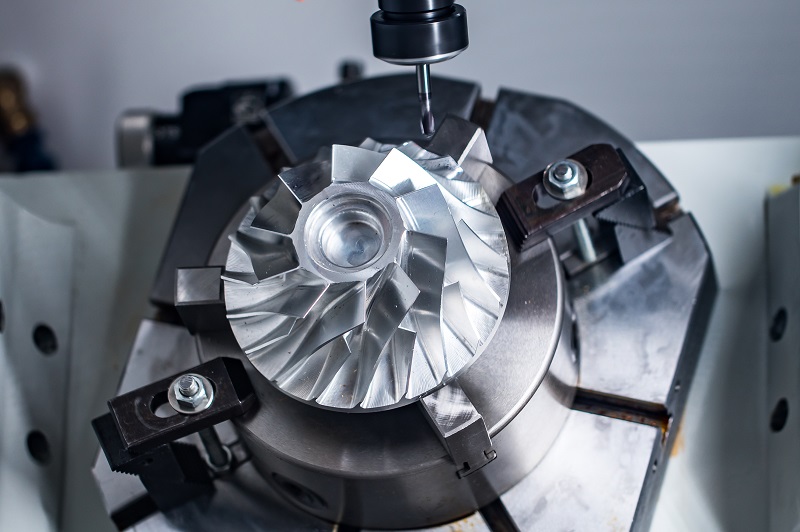

How to Manufacture Custom CNC Precision Components to a Higher Standard?

In precision CNC machining, where each component ultimately serves as part of a final assembly, it is essential to thoroughly understand the assembly methodology, functional purpose, and operational requirements of the end product before commencing machining operations. This foundational understanding allows for proper attention to critical tolerances and manufacturing processes, ensuring components are produced with assembly compatibility and optimal performance in mind. A case in point is our recent OEM project involving precision CNC machining parts and assembly, where the client provided comprehensive specifications regarding product application and functionality but limited tolerance requirements - necessitating our team to establish appropriate tolerance controls based on the component's actual operational demands. We will now proceed to discuss the following key aspects: auxiliary component selection, machining processes, cleaning and degreasing procedures, surface coating applications, and product quality inspection protocols.

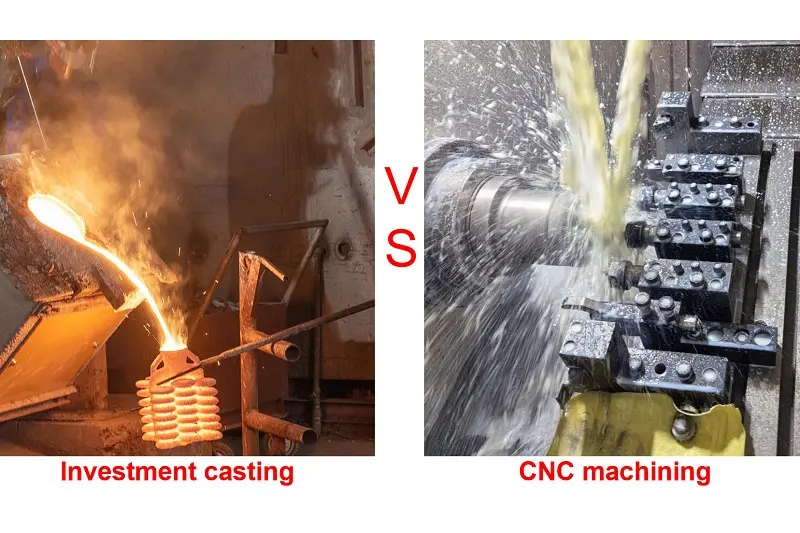

Why do some investment castings require dimensional correction?

Some custom investment castings are prone to deformation during production due to factors such as wax pattern distortion, structural design issues, mold shell warping after pouring, improper handling by workers during sand cleaning and shell shaking, heat treatment effects, or welding distortions during wax pattern assembly. These issues can lead to dimensional deviations or shape alterations, necessitating subsequent corrective measures. Correction is typically performed by applying external force, either at room temperature or elevated temperatures, and common methods include free correction, die correction, cold correction, and hot correction.

How to Produce Precision Casting Parts Better?

For investment casting parts, achieving true product excellence requires not only meticulous control during the casting process itself but also strict post-casting procedures to ensure high-quality output. This is especially critical for thin-walled parts, which often require supplementary processes to refine the castings and meet functional specifications. In OEM investment casting, many products demand tailored post-processing based on their actual application to guarantee compliance with performance requirements. Below, I will analyze several common auxiliary processes based on our recent production of specific components.

We provide CNC turning, CNC milling, CNC turn-mill compound machining, and metal investment casting services.

Dongguan SX is a full-service manufacturing partner offering one-stop precision machining solutions for global clients. Our comprehensive capabilities span CNC machining (including turning, milling, and turn-mill combined operations), metal investment casting (specializing in stainless steel, carbon steel, and hybrid casting-machining processes), heat treatment, surface finishing, and final assembly services. With extensive industry expertise, we distinguish ourselves through:

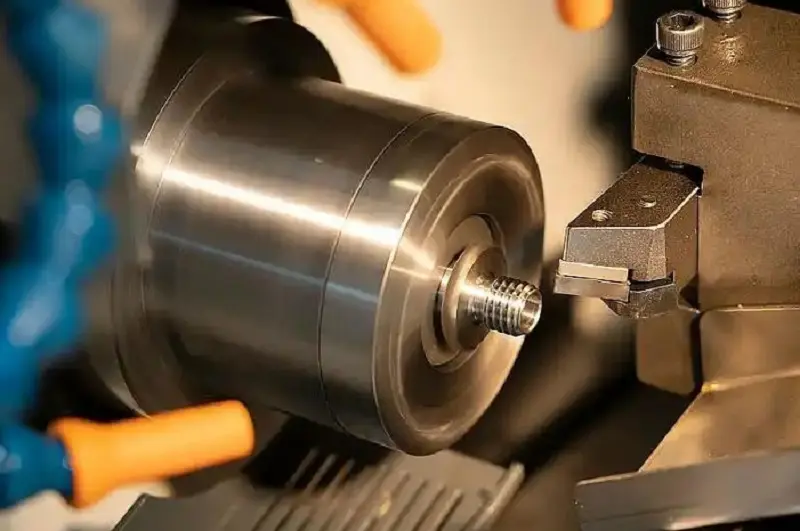

A typical case analysis of precision parts machining.

We have recently produced a rather special precision machining parts. Due to its special requirements, it is a relatively typical part. I would like to share it with you, hoping it can give you a reference.

The following two pictures are actual photos of the product after production. This product has the following special features. Let me analyze them with you.

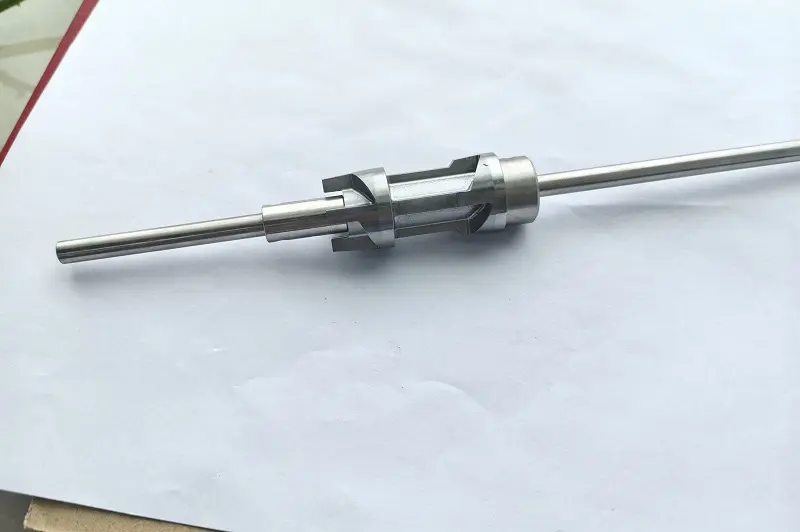

Case analysis of metal investment casting + CNC machining + polishing parts

We have just completed the production of a product. The structure of this product seems to be not difficult, but it is still difficult to produce it according to the customer's requirements. So, I would like to share this product with you.

Application of investment casting, CNC machining and welding in metal products.

We can see metal products in many manufacturing industries or daily necessities. How are metal products processed? In fact, metal products can be formed in many ways depending on their structures, such as stamping, powder metallurgy, forging, die-casting, precision casting, CNC machining, etc. Today I will share a metal product we produce, which includes the following processes: investment casting, CNC machining, carbonitriding heat treatment, welding and grinding, black phosphating surface treatment, etc. Please see the finished product picture below: