+86 180 0293 5268

+86 180 0293 5268

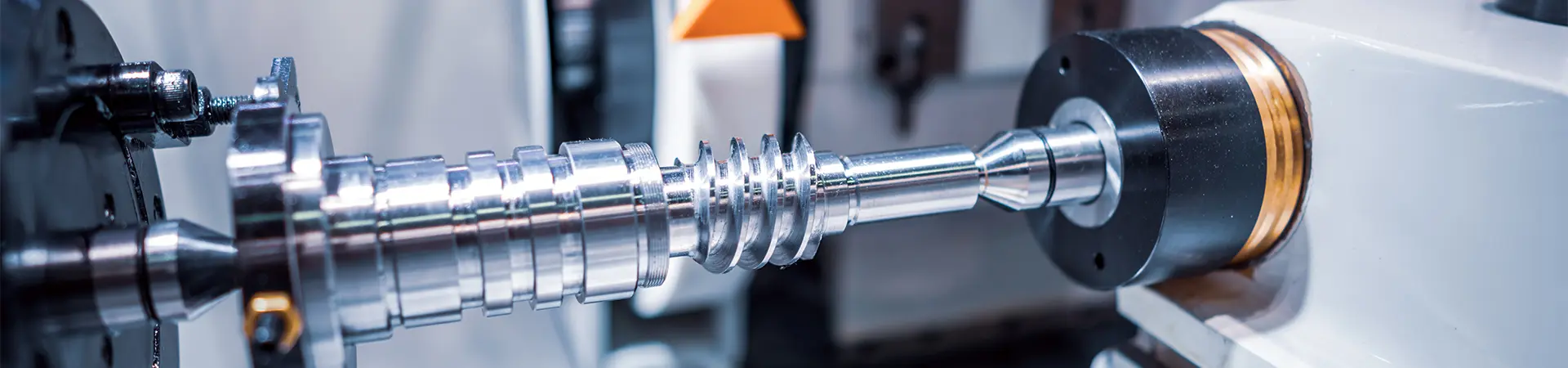

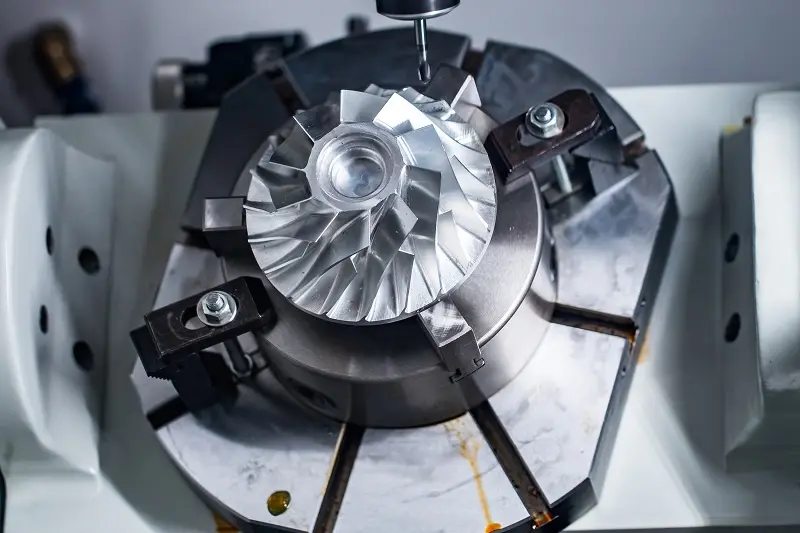

Cost-Effective CNC Turning & Milling Services

Characteristic

CNC machining offers high precision, efficiency, and flexibility, making it a cornerstone of modern manufacturing. First, its digital program control enables micron-level accuracy and excellent repeatability, ideal for mass-producing complex geometries and precision components. Second, automation significantly boosts productivity, allowing 24/7 operation with minimal defects—especially critical in aerospace, medical, and other high-demand industries. Additionally, features like automatic tool changers and multi-axis capabilities enable complete machining in a single setup, reducing lead times. Programmed operations minimize human error while seamless CAD/CAM integration accelerates prototyping. In summary, CNC machining outperforms traditional methods in precision, speed, consistency, and adaptability to complex parts, serving as a key enabler of smart manufacturing.

CNC machining delivers exceptional precision, achieving micron-level accuracy with high repeatability, making it ideal for complex aerospace and medical components. Its automated operation boosts efficiency, enabling 24/7 production with minimal waste while reducing labor costs. The technology offers remarkable flexibility through quick reprogramming and multi-axis capabilities, allowing intricate geometries to be machined in a single setup. However, CNC also presents challenges, including high initial investment in equipment and software, along with the need for skilled operators for programming and maintenance. While excellent for mass production, it faces competition from 3D printing for rapid prototyping and struggles with certain tough materials like hardened alloys. Despite these limitations, CNC remains indispensable for high-precision, high-volume manufacturing across critical industries.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

Professional CNC Machining Services: High-precision metal & plastic parts manufacturing, rapid prototyping, multi-axis machining (3-5 axis), and low-to-high volume production with strict quality control. Suitable for aerospace, automotive, medical, and industrial applications. Fast turnaround & competitive pricing.

description2