+86 180 0293 5268

+86 180 0293 5268

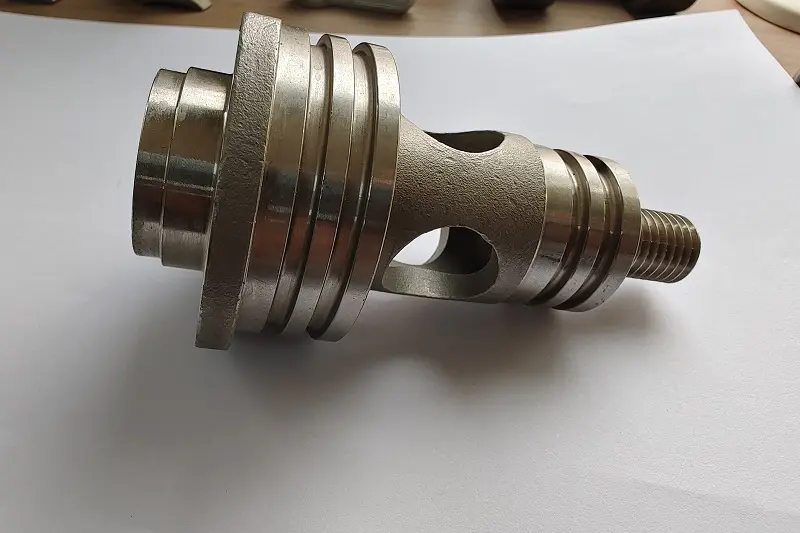

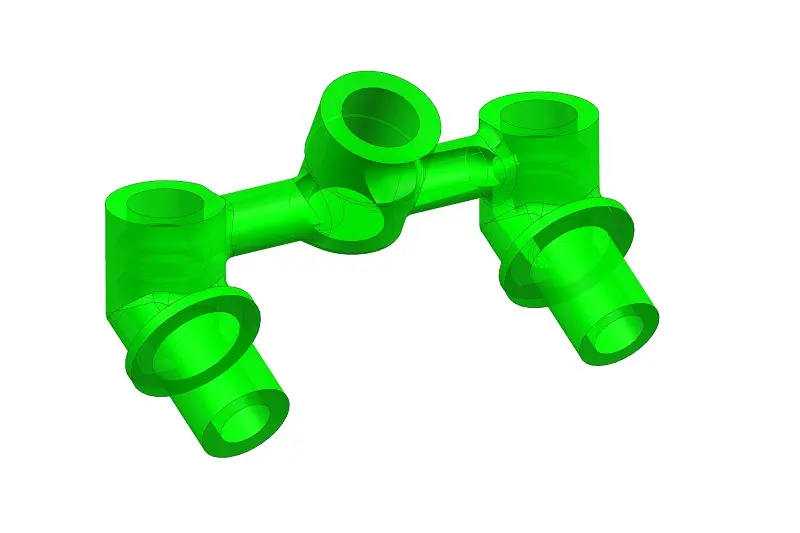

Custom Mechanical Hardware Parts Precision Casting Processing

Characteristic

Custom investment casting offers unparalleled production flexibility with no minimum batch restrictions, making it equally suitable for both small-scale and mass production. This adaptability allows the process to meet virtually any manufacturing requirement. Another key advantage is its ability to consolidate multi-component assemblies into single integrated parts through structural redesign - enabling complex components to be cast as monolithic pieces. This innovation not only reduces machining hours and raw material consumption, but also optimizes part geometry while lowering production costs. With these multifaceted advantages, investment casting has proven to be an indispensable component of modern precision casting technology.

The greatest advantage of investment casting components lies in their high dimensional accuracy and superior surface finish. This significantly reduces the need for machining during production, requiring only minimal machining allowances for critical areas of the part—or in some cases, allowing castings to be used directly after simple grinding and polishing without any machining at all. By adopting the investment casting process, manufacturers can achieve mass production while ensuring part consistency, as well as effectively avoid stress concentration issues caused by machining marks left by traditional cutting processes.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

We are far more than just an investment casting foundry – we are a comprehensive one-stop solution provider offering integrated OEM investment casting, shape correction, precision machining, heat treatment, surface finishing, and partial assembly services under one roof.

description2