+86 180 0293 5268

+86 180 0293 5268

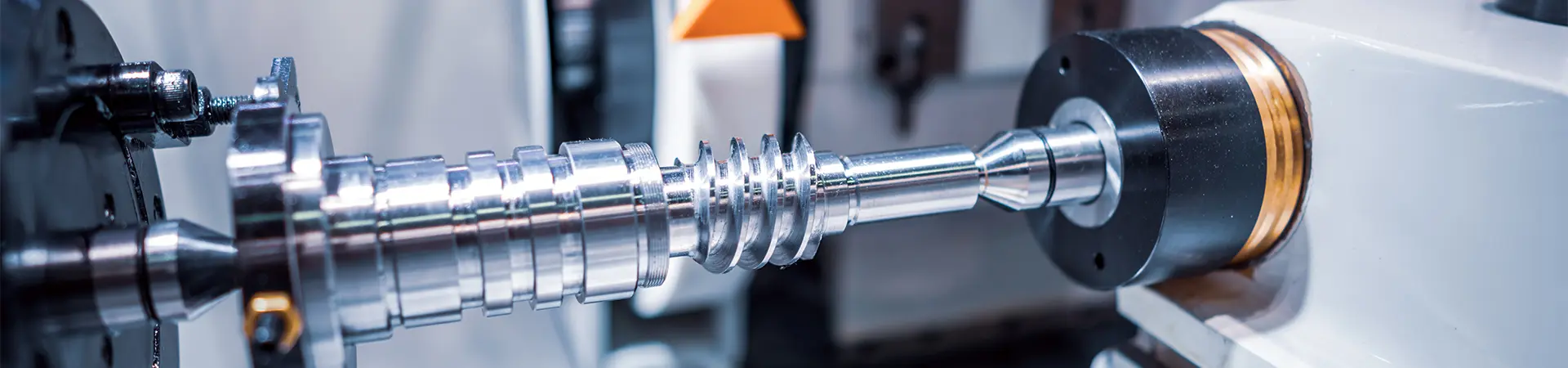

Custom metal CNC machining bicycle components

Characteristic

Bicycle components, especially connecting parts, demand high machining precision. CNC machining is ideally suited for this, as it typically achieves tolerances within millimeter or even micron levels, ensuring strict adherence to dimensional and geometric design requirements. This is particularly critical for components like frame joints, where precision and stability in curved surface machining are essential to guarantee assembly reliability and long-term durability. Additionally, many bicycle parts are appearance-oriented and require high aesthetic standards. CNC machining produces surfaces with excellent and uniform finishes, providing an ideal foundation for subsequent treatments such as anodizing or electroplating, thereby achieving highly attractive final components.

CNC machining services are widely utilized across industries such as aerospace, medical, motorcycle, and bicycle manufacturing, owing to their exceptional precision, high production efficiency, broad material compatibility, and advanced automation and intelligence. With continuous technological advancements, precision CNC machining has become an indispensable technology in modern manufacturing, helping enterprises enhance competitiveness and drive innovation within the industry. However, for components with complex structures, CNC machining tends to involve higher costs compared to processes like precision casting, die-casting, or forging. Nevertheless, it delivers the best overall results in terms of quality and performance.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

We deliver high-quality and consistently reliable precision CNC machined parts, widely used in industries such as aerospace, marine, medical, offshore, and automotive (including motorcycles and bicycles).

description2