+86 180 0293 5268

+86 180 0293 5268

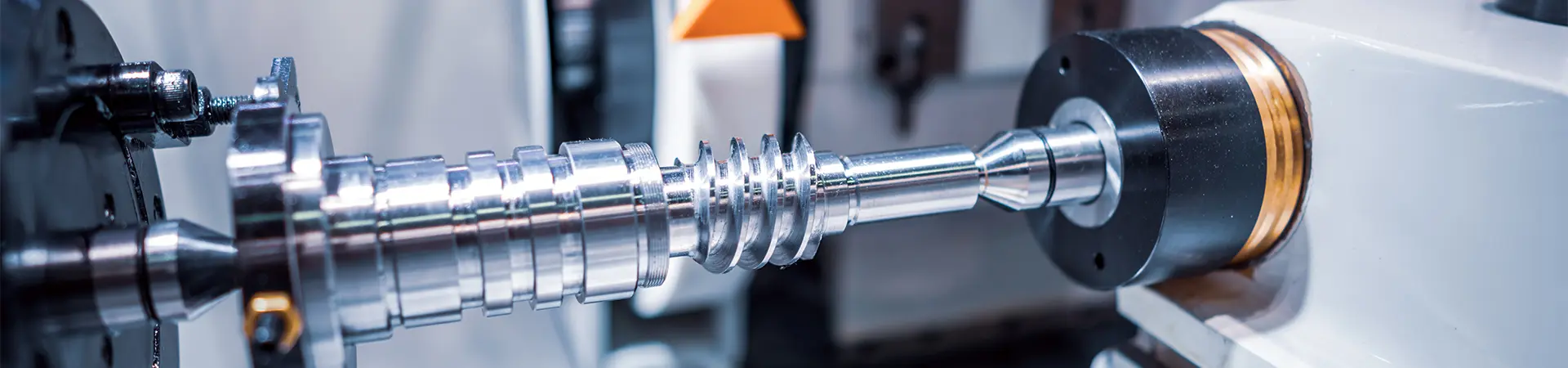

Custom Metal Parts CNC Turning Services

Characteristic

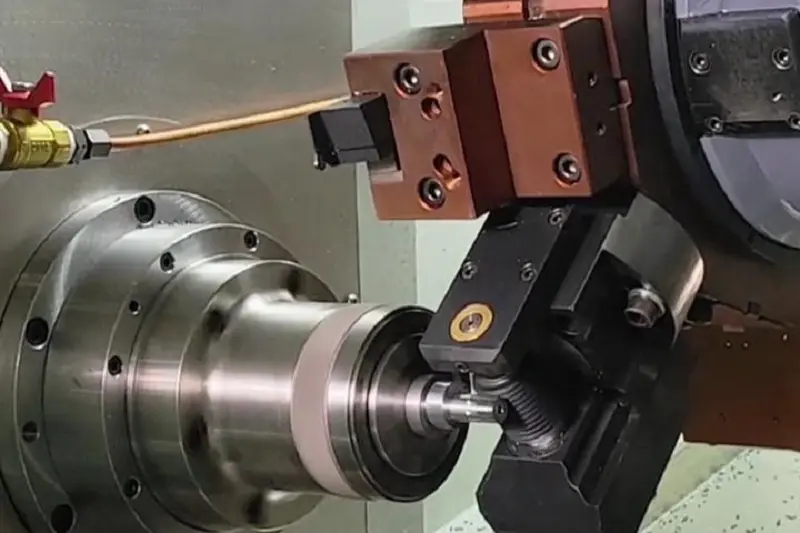

Turning machining is most commonly used to process rotational parts such as shafts, discs, sleeves, threads, and similar components. CNC lathes offer high and stable precision when machining such parts, along with high efficiency and relatively low costs. They are also capable of processing a wide range of materials, including stainless steel, alloy steel, aluminum, copper, titanium alloys, plastics, and more. Producing turned parts only requires programming on the machine, followed by clamping and tool setting — no complex steps such as molds are needed. As a result, turning is suitable for both small-to-medium batch production and large-scale manufacturing. However, as industry continues to advance, part requirements are becoming increasingly demanding, leading to the growing adoption of turn-milling compound machining.

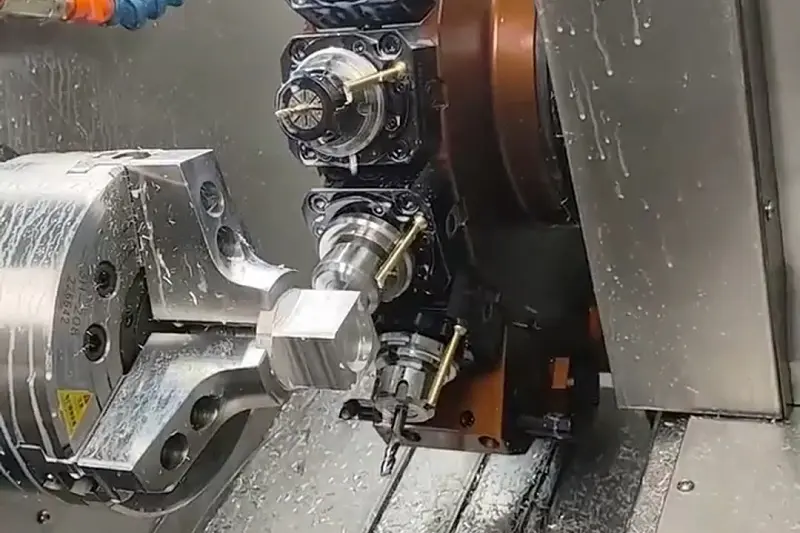

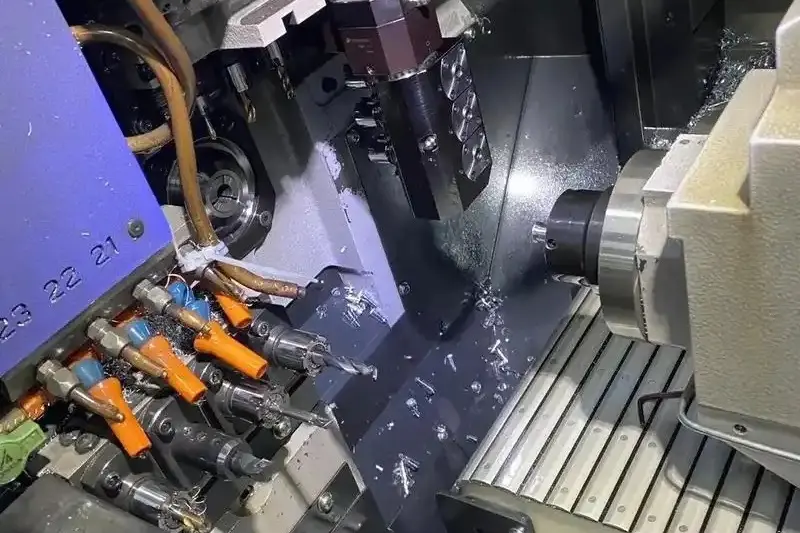

With the advancement of society and technology, customer demands for products have become increasingly stringent, requiring us as component manufacturers to continuously enhance our technical capabilities to meet these expectations. Turned parts remain widely used across industries, yet today's demands for more sophisticated product functions often lead to increasingly complex structural designs. In many cases, conventional CNC turning alone can no longer fulfill these requirements. As a result, more and more components now rely on turn-milling compound machining or are produced using dual-spindle or multi-turret lathes to satisfy advanced machining needs. We possess extensive experience in manufacturing parts with high precision and highly complex structures.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

We offer a full range of CNC turning services, including CNC turret lathe machining, CNC sliding headstock (Swiss-type) lathe machining, CNC turn-milling compound machining, dual-spindle turn-milling compound machining, as well as various other CNC machining services.

description2