+86 180 0293 5268

+86 180 0293 5268

Custom Stainless Steel Investment Casting Valves

Characteristic

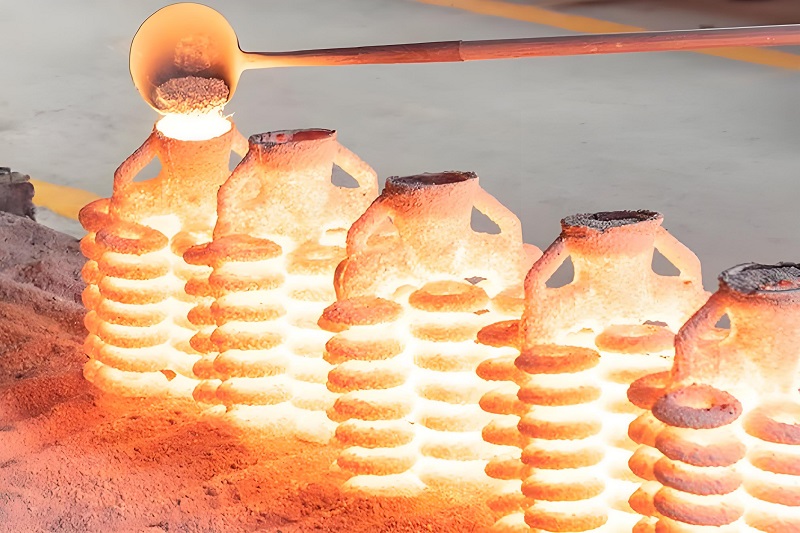

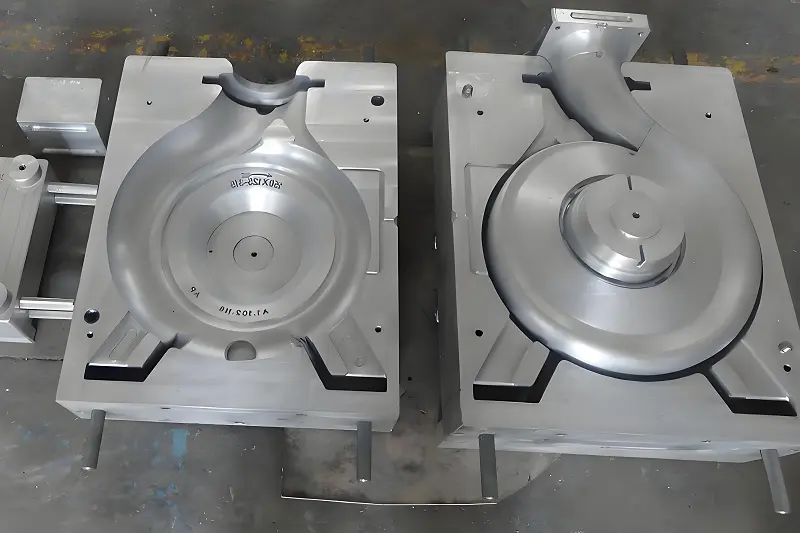

Investment casting enables unparalleled design flexibility, allowing intricate internal passages, thin walls, and optimized flow paths that machining or sand casting cannot achieve. The superior metallurgical integrity of our stainless steel valves (304/316/17-4PH) ensures exceptional corrosion resistance, even in high-temperature/pressure environments like offshore rigs or chemical plants. The near-net-shape process minimizes material waste and secondary machining, reducing lead times and costs. With surface finishes reaching Ra 3.2μm or better and tolerances within ±0.005 in/in, these valves outperform conventional alternatives in leak prevention and longevity. Our valves undergo 100% testing to guarantee fatigue resistance and crack-free performance. Ideal for cryogenic to 800°C applications, they combine lightweight durability with zero porosity—critical for ISO 5208 Class VI shut-off.

With decades of specialization in investment casting, we combine precision engineering with cost-efficient production to deliver superior stainless steel valves. Our in-house process control ensures consistent quality, from wax patterns to final machining, while advanced metallurgical expertise guarantees optimal material performance. We offer fast prototyping and flexible MOQs, supported by strict ISO-compliant testing. By integrating design optimization with manufacturing, we reduce lead times by 30% versus industry standards, providing clients with high-performance valves at competitive pricing—all backed by full traceability and technical support.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

Precision-cast stainless steel valves, tailored to your specs. Fast turnaround, strict quality control, competitive pricing. Your reliable global casting partner.

description2