+86 180 0293 5268

+86 180 0293 5268

Custom titanium fittings for the medical Industry

Characteristic

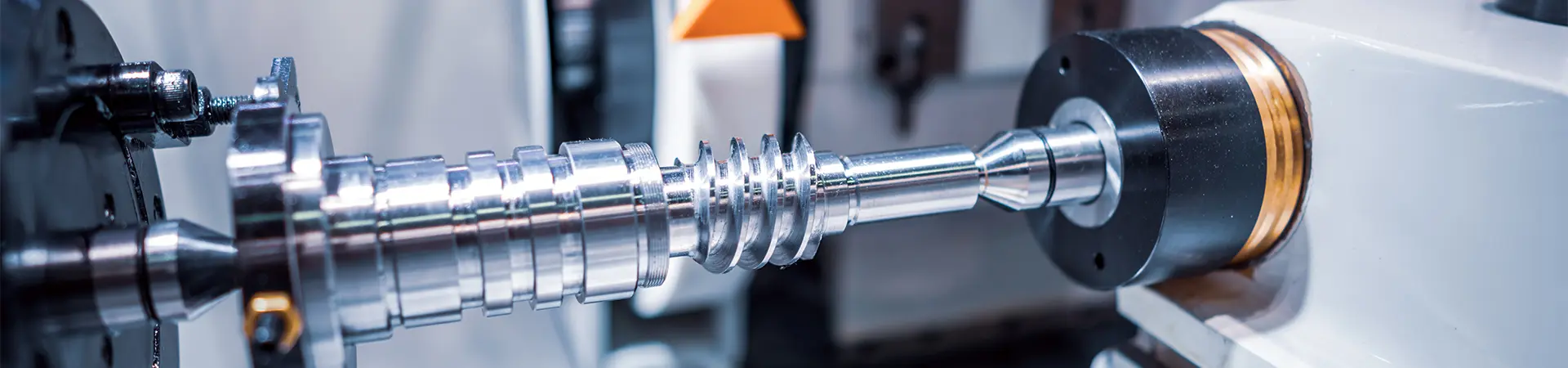

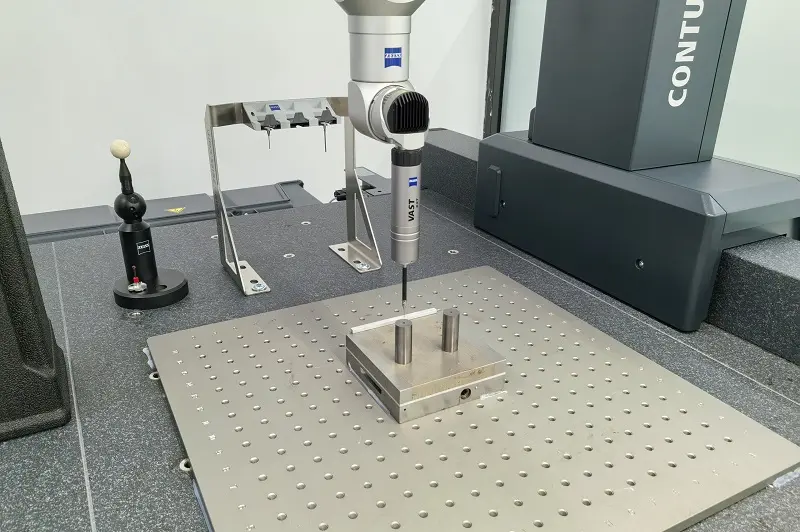

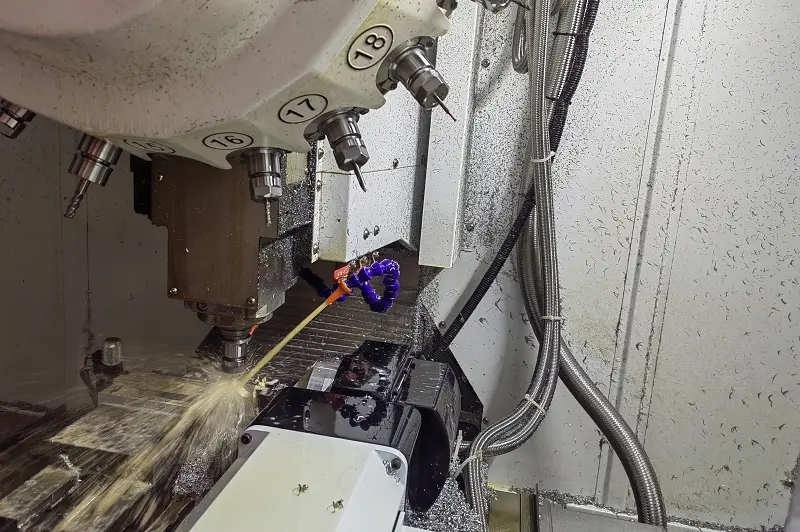

Titanium alloy is a high-strength, low-density, and highly corrosion-resistant metal material widely used in demanding or extreme environments, including aerospace, medical devices, sporting goods, and chemical industries. The machining processes for titanium alloy parts are diverse, including common methods such as turning, milling, grinding, casting, forging, and stamping. Among these, turning and milling are the most frequently used; however, due to titanium's unique properties—such as high strength, poor thermal conductivity, and significant thermal expansion—machining titanium components presents considerable challenges, requiring special attention to machine tools, cutting instruments, temperature control, and other critical factors.

Titanium alloy is a high-hardness material with poor machinability, so when designing titanium components, factors such as part geometry, dimensional accuracy, and surface roughness must be carefully considered. The structural design should also account for titanium's unique properties to avoid stress concentration and corrosion risks. Close collaboration with machining factories during the design phase is essential to ensure both feasibility and manufacturing efficiency. Custom titanium machining is a complex and precision-driven process that requires multidisciplinary expertise and technical support throughout.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

We specialize in precision machining of custom parts, with particular expertise in titanium alloy machining—including turning, milling, and turn-mill compound machining. Backed by deep technical knowledge and extensive experience, we deliver high-quality solutions tailored to your requirements. For collaboration or inquiries, please contact us at info@dgsxltd.com. We welcome opportunities to exchange insights and explore new possibilities together.

description2