+86 180 0293 5268

+86 180 0293 5268

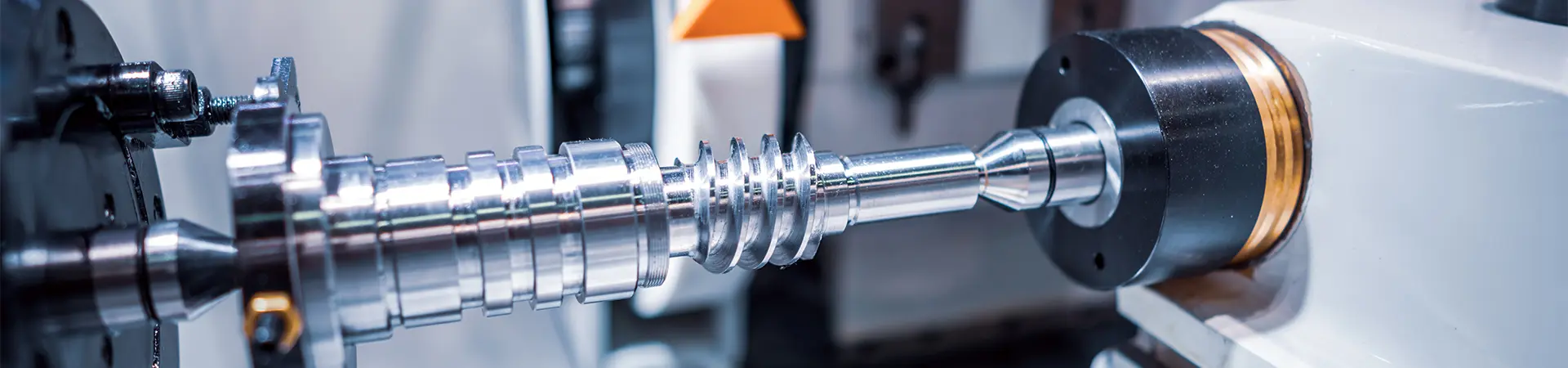

Custom Titanium Machining Parts for Machinery and Equipment

Characteristic

The machining of titanium alloy components

typically includes CNC machining, thermal processing, chemical processing, and

electrical machining, among others. Among these, CNC machining refers to the

precision forming of titanium alloy materials using metalworking machine tools.

Known for its high precision and efficiency, CNC machining is widely used in

manufacturing various titanium alloy products, such as custom titanium bolts,

nozzle components, satellite brackets, marine parts, and marine hardware.

Common CNC machining techniques include milling, turning, boring, grinding, and

drilling. Selecting the appropriate machining method ensures optimal

utilization of titanium alloy's unique properties—such as high

strength-to-weight ratio and corrosion resistance—to meet diverse industrial

demands. Due to its versatility and reliability, titanium CNC machining remains

one of the most prevalent manufacturing methods for titanium alloy components

in industries like aerospace, marine engineering, and high-performance

automotive sectors.

Despite its relatively short history of application, titanium and its alloys have earned prestigious titles such as "space metal" due to their exceptional properties. Known for their light weight, high strength, and heat resistance, titanium alloys are particularly suitable for manufacturing aerospace components and parts used in extreme environments. CNC machining is a widely adopted method for processing titanium alloy parts; however, due to titanium's poor thermal conductivity and high hardness, machining requires advanced machine tools, specialized cutting tools, and optimized parameters. For instance, critical components like titanium alloy bolts are predominantly produced using CNC machining to ensure precision and structural integrity.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

We offer comprehensive CNC machining services for a wide variety of titanium alloy components along with professional surface treatment solutions. Our precision-engineered titanium parts are extensively utilized in demanding applications across marine engineering projects, shipbuilding components, and critical medical equipment manufacturing, leveraging titanium's exceptional corrosion resistance, high strength-to-weight ratio, and biocompatibility to meet the stringent requirements of these specialized industries.

description2