+86 180 0293 5268

+86 180 0293 5268

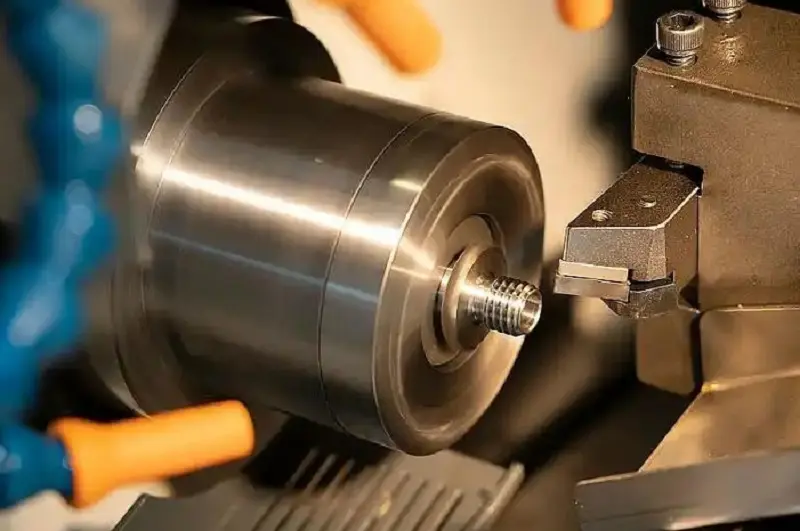

Which types of parts are suitable for CNC turning?

CNC turning is one of the indispensable and critical CNC machining methods in modern manufacturing. It enables automated processing through numerical control technology, allowing for the efficient and precise machining of a wide range of complex parts. Compared with conventional turning machining, CNC turning offers higher production efficiency and greater machining accuracy, making it suitable for processing various types of components.

What are the advantages of aluminum alloy in precision CNC machining?

In the field of precision CNC machining, material selection directly influences processing efficiency and product quality. Aluminum alloy stands out in CNC machining due to its unique combination of properties, making it one of the preferred materials across various industries such as aerospace, consumer electronics, and automotive manufacturing—rightly earning it the title of the "Lightweight Artisan" of modern manufacturing. As a high-precision forming technology, CNC machining of aluminum alloy demonstrates broad application value in numerous fields, leveraging its distinct advantages. It integrates high-quality aluminum alloy materials with advanced CNC technology, solidifying its critical role in machining processes. Next, let's explore some of the key advantages of aluminum alloy in precision CNC machining.

What are the challenges in CNC turning of stainless steel parts?

Precision CNC turning is typically used for machining rotary parts that can be securely clamped on a lathe. CNC lathes are characterized by high rigidity, precision manufacturing, and accurate tool setting. They allow for straightforward and precise manual or automatic tool compensation, enabling the machining of parts with stringent lathe accuracy requirements. Moreover, the tool movement in numerically controlled turning is achieved through high-precision interpolation and servo drive systems. When machining arcs or other curved surfaces, this method produces shapes that more closely conform to the geometric requirements of the design drawings compared to copy lathes.

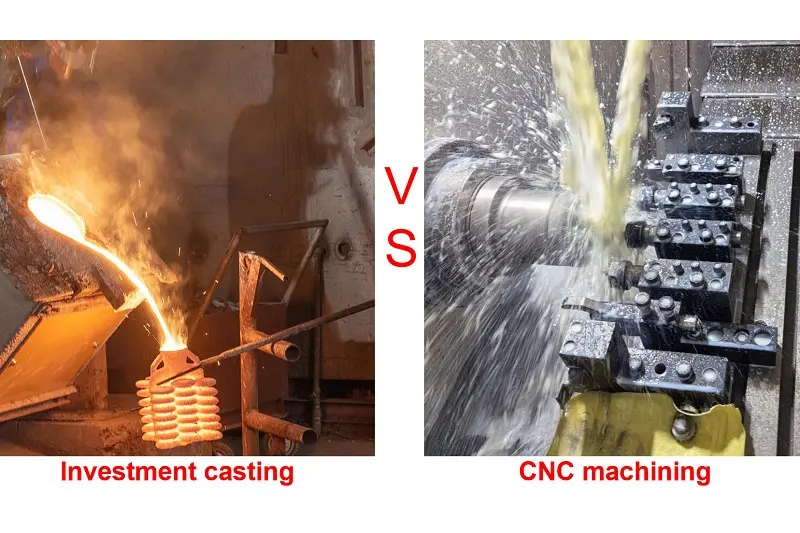

How to Understand Investment Casting?

Investment casting, a sophisticated process that transforms wax patterns into precise metal components, can be classified into three main types based on the shell material used: silica sol casting, sodium silicate (water glass) casting, and composite casting. Also known as the "lost wax casting" process, this method involves multiple steps—including wax pattern creation, shell building, dewaxing, metal pouring, and post-casting treatment—to produce parts with exceptional dimensional accuracy and superior surface finish.

How to Choose Between Investment Casting and CNC Machining?

Investment Casting is a process that involves pouring molten metal into a mold. With a history of over 3,000 years in China, it remains widely used today. Advances in investment casting technology now allow for the production of high-quality parts with tight tolerances. This differs from CNC Machining, a relatively newer manufacturing method that is also extensively used.

How to Reduce Porosity in Metal Casting?

Gas porosity is one of the common defects in precision casting, manifesting as smooth holes that appear in specific internal or surface areas of the castings. These pores are typically only detected after machining. The formation of such cavities is primarily due to gases failing to escape in a timely manner during the investment casting process. To minimize these defects, it is essential to conduct an in-depth summary of the causes and preventive methods of gas porosity in metal casting.

Why are titanium alloys difficult to CNC machining?

In the CNC machining industry, titanium alloy is recognized as a high-performance material due to its high strength, low density, excellent thermal stability, and corrosion resistance. In recent years, the use of titanium alloy components, such as titanium screws, has been increasing annually. However, titanium alloy is considered a difficult-to-machine material, primarily due to the complex physical phenomena during machining, where thermal effects, elastic deformation, and work hardening interweave, leading to short tool life and challenges in ensuring part accuracy. Particularly in CNC machining, processing titanium alloy poses significant challenges in tool selection, path planning, and parameter matching. Inappropriate machining methods can exacerbate tool wear, generate excessive heat and stress deformation, and ultimately compromise part precision. Therefore, understanding the difficult-to-machine characteristics of titanium alloy, selecting appropriate tools, optimizing cutting parameters, and applying advanced programming techniques are key to addressing these challenges. Below, we analyze in detail why titanium alloy is so difficult to machine with CNC from the following perspectives.

What is a 316 stainless steel casting?

A 316 stainless steel casting is a component manufactured using the casting process with stainless steel 316 as the raw material. Since stainless steel 316 offers properties such as corrosion resistance, high-temperature resistance, and high strength, 316 stainless steel castings inherently share these characteristics. Consequently, they are commonly employed in demanding environments requiring corrosion resistance, high temperature, and high pressure, especially in fields like marine engineering, chemical processing equipment, and medical devices. They play a critical role by maintaining performance over long periods in humid and corrosive conditions without failure.

What are titanium screws used for?

Titanium screws are widely utilized across various advanced industries due to their unique properties, such as low density, high strength, excellent corrosion resistance, superior heat and cryogenic resistance, non-magnetic characteristics, and non-toxicity.

Compared to traditional stainless steel screws, titanium screws demonstrate greater flexibility and oxidation resistance, making them more suitable for a broader range of specialized applications. Particularly in high-pressure environments, titanium screws exhibit significantly better compressive strength than ordinary stainless steel screws.

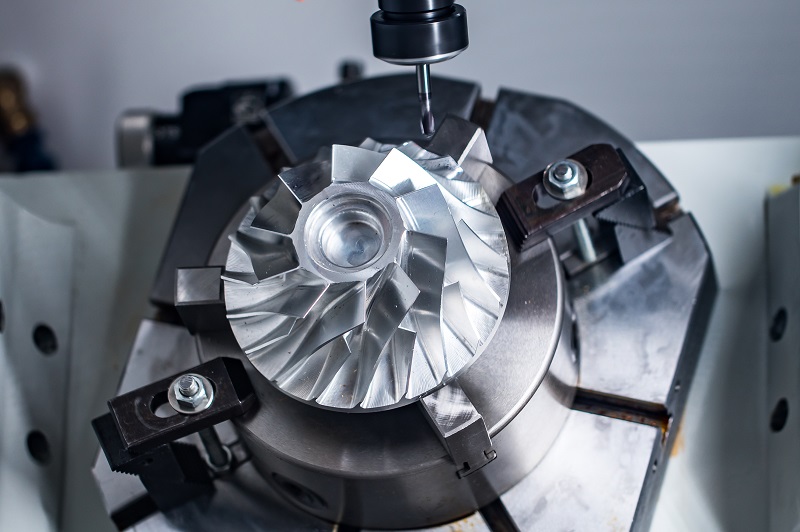

Why is CNC machining widely used for so many components?

In modern manufacturing, CNC machining is supplanting traditional processes at an unprecedented rate, establishing itself as the gold standard for precision component production. Renowned for its superior precision, efficiency, and dependability, precision CNC machining has become the technology of choice for a multitude of industries. From aerospace and automotive manufacturing to electronics, medical equipment, and marine engineering, it delivers unparalleled benefits. This analysis will deconstruct the rationale behind this phenomenon across multiple dimensions—including efficiency, accuracy, and flexibility—to illuminate how CNC machining is fundamentally shaping industrial production.