+86 180 0293 5268

+86 180 0293 5268

Business Combination and Corporate Relocation.

It is important to emphasize that SCZY and SX remain part of the same corporate entity. The establishment of two companies serves solely to specialize in catering to distinct customer segments—domestic and international—while maintaining our unwavering commitment to consistent values and service quality. Below is an overview of both companies:

-

1. Shenzhen SCZY Technology Co., Ltd (SCZY)

SCZY, established in 2011, is a high-tech enterprise that began as a compact team of just a few professionals. Initially specializing in the domestic Chinese market, the company provided customized fixtures for the aerospace industry, bespoke non-standard precision components, and stainless steel investment castings. Thanks to our team's unwavering commitment to stringent quality control, on-time delivery, and robust long-term after-sales support, we have consistently earned high praise from all our clients.

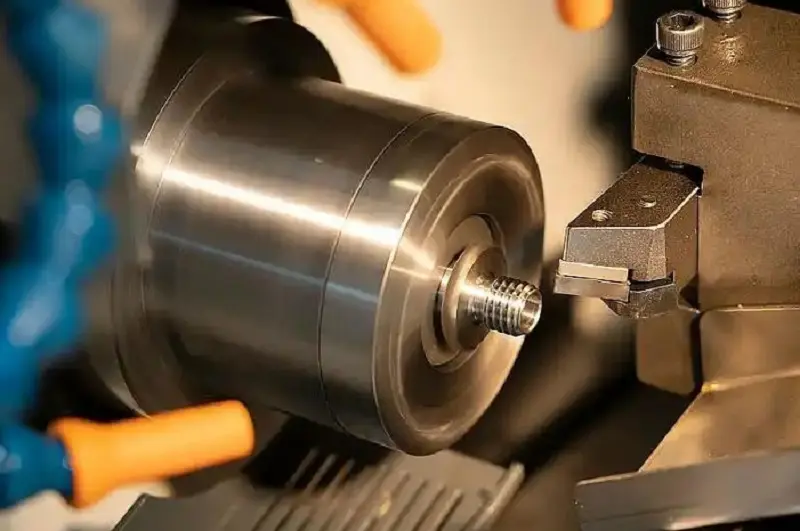

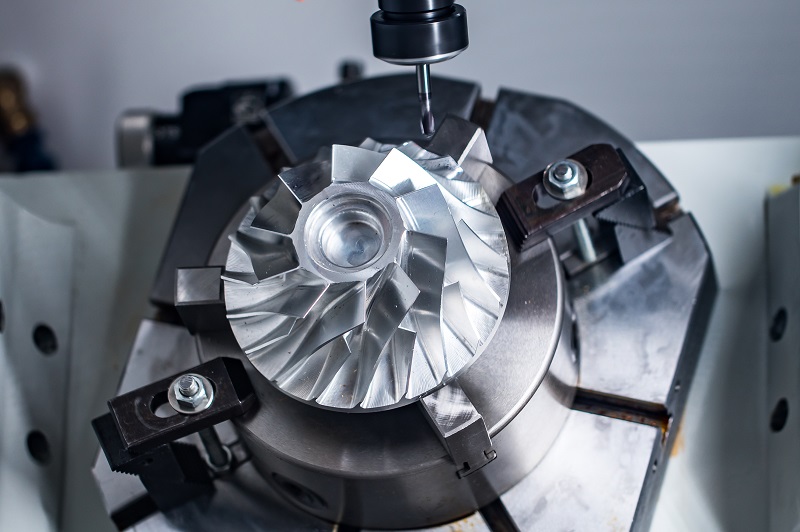

With the company's continuous development, we established a dedicated international trade team in 2016. While our core service scope remained unchanged—focusing on precision CNC machining parts, precision investment casting parts, and component assembly per client requirements—our global footprint began to expand significantly. Over time, we gradually extended our services to include sourcing standard components and equipment from other Chinese manufacturers on behalf of our clients, as well as developing non-standard custom products that required external collaboration.

Our Technical Director, Caden, brings over 22 years of extensive experience across multiple manufacturing sectors, including molding, injection molding, precision machining, casting, and stamping. Under his leadership, our team conducts thorough pre-production analysis to identify and mitigate potential issues before manufacturing begins. We are adept at performing real-time analysis and implementing improvements for any problems arising during production. Furthermore, every finished product undergoes rigorous quality control. Should any discrepancies occur, we maintain proactive communication with our clients to coordinate and provide effective solutions.

In our international trade operations, we uphold the same stringent principles: strict quality control, unwavering commitment to delivery schedules, and robust after-sales service management. This consistent dedication has earned us high recognition from the majority of our clients, with many evolving into long-term strategic partners.

2. Dongguan SX Technology Co., Ltd (SX)

SX, established in 2024 as a subsidiary of SCZY, is dedicated exclusively to managing SCZY's international trade operations and after-sales services. Upholding the same core principles and service commitment as our parent company, we take full responsibility for our clients' product quality, delivery timelines, and post-sale support.

The core principle for both SCZY and SX is: Service Supremacy. We hold ourselves accountable for every client and every project. We recognize that no individual or company is perfect; what truly defines us is not flawlessness, but responsibility.

Even the most exemplary companies can encounter issues. An error itself is not what matters most; what truly counts is our ability to promptly confront the situation, address it effectively, and, most importantly, minimize any impact or loss for our client. That is the definitive solution.

For instance, we recently encountered a challenge with a thin-walled CNC parts made from 316 stainless steel. Its minimal wall thickness necessitated machining from tubing, which included cutting a slit. This process introduced stress, causing deformation and a resultant reduction in both the inner and outer diameters. Our initial solution was to anneal the material before machining to relieve these stresses. While annealing successfully eliminated the stress, it also reduced the material's springback elasticity. Crucially, the part's application required good resilient force. Ultimately, the client reported insufficient elasticity during use.

Upon receiving this feedback, our team immediately analyzed the root cause, maintained proactive communication with the client, and presented solutions. Through a collaborative effort, we produced and delivered a new batch of conforming parts in the shortest possible timeframe, successfully preventing any significant loss for the client.

We share this case not to highlight the problem, but to demonstrate our commitment. We cannot guarantee that every product will be 100% flawless, but we can absolutely guarantee that when an issue arises, our team will mobilize with utmost speed to analyze it and implement a solution, all with the primary goal of preventing or minimizing loss for our clients.

We welcome your feedback and guidance at info@sczyltd.com or infon@dgsxltd.com. We are committed to continuous improvement and strive to get better every day.