+86 180 0293 5268

+86 180 0293 5268

How to Choose Between Investment Casting and CNC Machining?

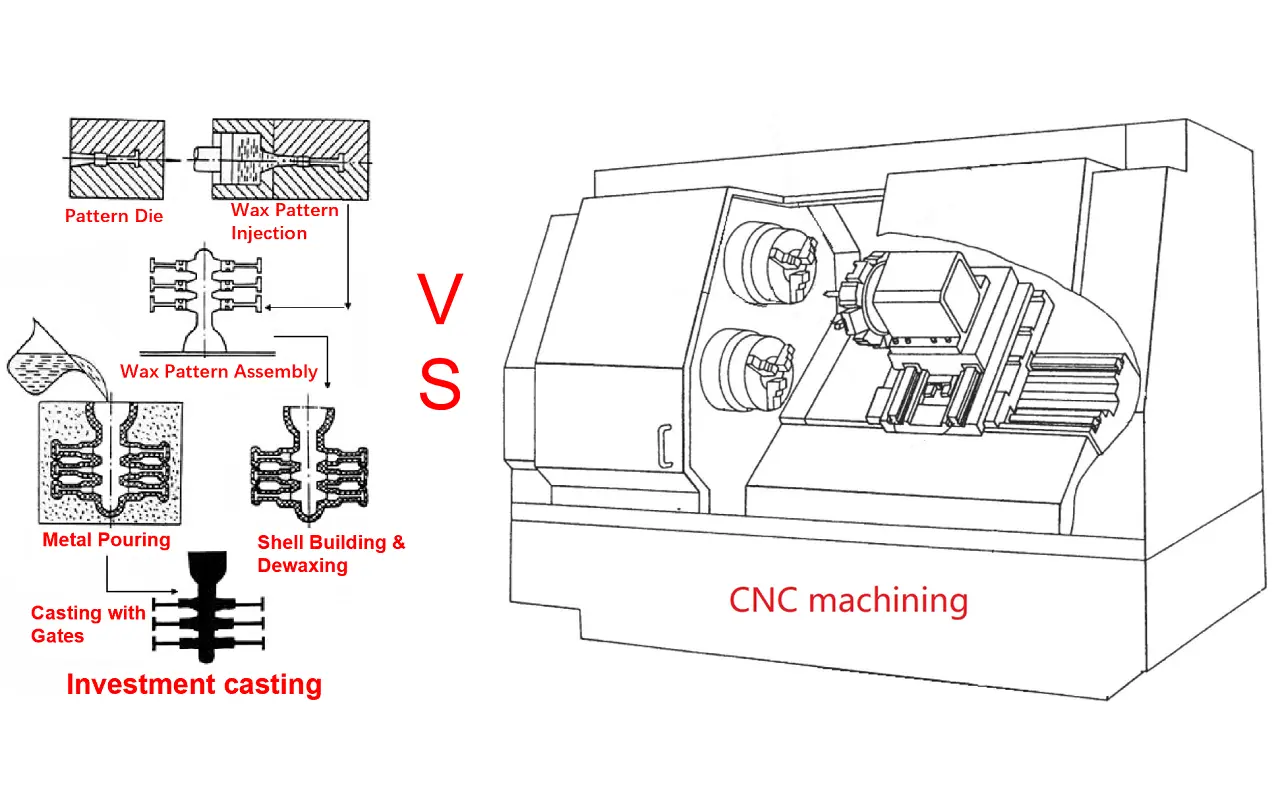

Investment Casting is a process that involves pouring molten metal into a mold. With a history of over 3,000 years in China, it remains widely used today. Advances in investment casting technology now allow for the production of high-quality parts with tight tolerances. This differs from CNC Machining, a relatively newer manufacturing method that is also extensively used.

So, for end-users, how do we decide? Should we choose CNC machining, investment casting, or perhaps a combination—starting with investment casting followed by secondary CNC machining? Which approach is most suitable?

To answer this, we will first discuss the distinct characteristics of these two manufacturing processes and provide a general overview of each.

Investment Casting is a formative manufacturing process. It begins with creating a wax pattern using a mold. This wax pattern is then used to form a ceramic shell. Molten metal is poured into this shell. After the part cools and solidifies, it is cleaned and finished to achieve the desired surface quality. Sometimes, this post-processing includes CNC machining to achieve tighter tolerances or to create features that are not suitable for casting.

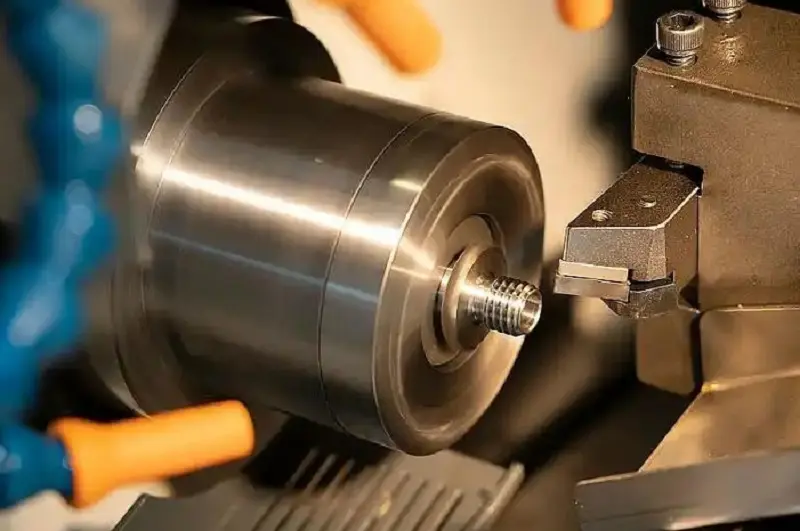

CNC Machining is a subtractive manufacturing method. In this process, cutting tools remove material from a solid block to achieve the desired geometry. A computer program using G-code directs the machine on where to move and how to cut. Precision CNC machining produces high-accuracy parts with very tight tolerances, capable of achieving extremely high levels of precision.-

Criteria for Choosing Between Investment Casting and CNC Machining

- 1. Selection Based on Part Geometry

The choice of the right manufacturing technology begins with considering the part geometry. For instance, some designs require the removal of large amounts of material, which is both time-consuming and leads to significant waste. Such designs are often ideal for investment casting—examples include hollow parts with thin walls and large cavities. Complex geometries are also well-suited for investment casting, as they would take an excessively long time to machine. Internal cavities are typically a good fit for investment casting as well, since machining them with CNC can be highly complex. This is especially true for sealed internal cavities that would otherwise require assembly or metal joining processes in addition to CNC machining.

CNC machining is excellent for thick parts requiring high precision. Sharp edges or corners are not ideal for investment casting. Large or oddly shaped parts with thick walls are also more suitable for CNC machining, as these geometries are difficult to fill and cool uniformly during the metal casting process.- 2. Selection Based on Material

Metal casting generates less material waste compared to CNC machining. Apart from a small amount of metal in the sprue, runners, and gates, the casting process uses only the material needed for the final part. This excess material is easily removed, remelted, and reused for another component. In contrast, CNC machining produces relatively more waste material.

The range of material choices for investment casting is much narrower than for CNC machining. Nearly all alloys can be machined via CNC.- 3. Selection Based on Production Speed

The lead time for the investment casting process is typically several weeks, as it requires mold creation first. However, once the mold is completed, the casting process itself is very fast, making it advantageous for producing large quantities of parts. CNC machining, on the other hand, offers faster production speeds for smaller batches, enabling quicker turnaround without the wait for mold fabrication.

- 4. Selection Based on Repeatability and Precision

Repeatability is crucial in manufacturing. The investment casting process produces highly repeatable parts. Once the mold and process parameters are dialed in, each part can be nearly identical. CNC machining is also an exceptionally repeatable and precise process, capable of achieving tighter tolerances than investment casting.

-

- 5. Selection for Prototyping

If you are in the prototyping stage of the design process, investment casting is generally not a good choice. Creating molds takes a long time, and any design changes necessitate mold modifications or complete remanufacturing, resulting in low efficiency and high costs. In this scenario, CNC machining is the better option.

- 6. Selection Based on Volume and Requirements

During the initial prototyping phase, you likely don't need many parts, so CNC machining makes more sense. The variability of future requirements is another factor. If frequent product changes are anticipated, CNC machining may be the better choice. However, if the design is stable, no changes are expected, and production volume is steady, then using investment casting is an excellent option.

-

Regarding whether to use investment casting or precision CNC machining to produce a part, there is no absolute answer. Each method has

its own distinct advantages. For many parts, either process could be suitable;

the choice primarily depends on which aspects the user prioritizes.

Furthermore, these two methods often complement each other. Many metal parts

can undergo secondary CNC machining on critical areas after being produced via

investment casting. This combined approach not only improves overall efficiency

but can also reduce manufacturing costs. As for which processing method we

choose, we need to thoroughly understand our specific requirements before

making a final decision.