+86 180 0293 5268

+86 180 0293 5268

How to choose between using investment casting or sand casting?

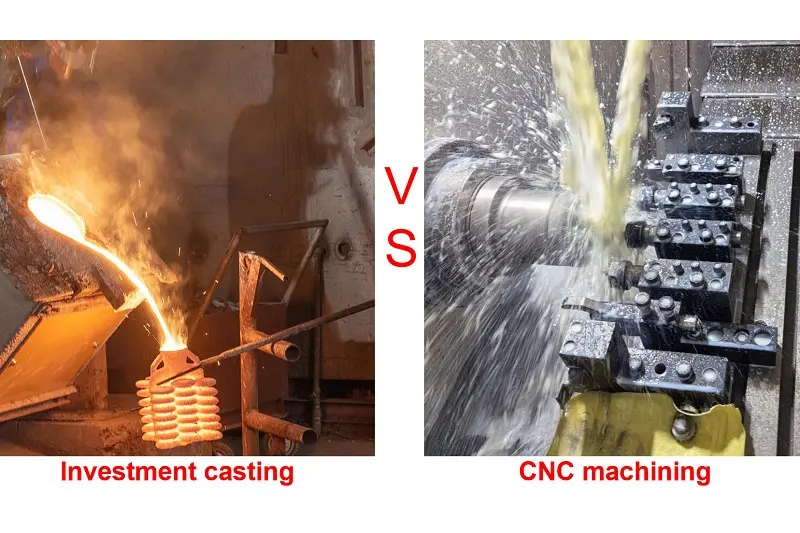

Investment casting and sand casting are both metal casting processes. First, let's understand how each one works. Sand casting is one of the most common and simplest manufacturing methods, used for centuries. It primarily relies on foundry sand and sand binders. Sand casting refers to the process of producing castings in sand molds. It can be used for steel, iron, and most non-ferrous alloy castings. Due to the low cost and wide availability of molding materials, as well as the simplicity of mold preparation, sand casting is suitable for single-piece, batch, and mass production. It has long been a fundamental process in foundry production.

On the other hand, investment casting, also known as lost-wax casting, involves steps such as wax injection, wax pattern correction, pattern assembly, slurry dipping, wax melting, metal pouring, and post-processing. In lost-wax casting, a wax pattern of the desired part is created, then coated with a ceramic slurry to form a mold. After drying, the mold is heated to melt and remove the wax. The hollow mold is then fired to become a ceramic mold. Usually, a pouring gate is designed during mold making. Molten metal is poured through this gate, and after cooling, the desired part is formed.

So, for our parts, should we choose investment

casting or sand casting? In fact, both have their own advantages, and it’s not

possible to simply say one is better than the other. The choice depends on the

specific requirements of the casting. Next, we will analyze their differences

in the following aspects to help decide which process to select.

-

-

1. Their Respective Advantages

- Advantages of Sand Casting

- High Versatility: There are no specific constraints regarding product structure, complexity, casting material, or weight. It can meet the production needs of various castings such as machine tool accessories, mechanical hardware, and automotive/motorcycle parts.

- High Production Efficiency: It can achieve mechanized and automated production modes. With advancements in casting technology and the use of high-precision casting molds, the accuracy grade of sand casting has significantly improved.

- Relatively Low Cost: The process is simple, costs are relatively low, and it is suitable for producing large and complex castings.

- Wide Application: Globally, sand casting is the most widely used casting method.

- Advantages of Investment Casting

- High Precision for Metal Castings: Compared to sand casting, investment casting offers higher precision, allowing for smaller machining allowances.

- Excellent Surface Quality: Investment casting provides better surface roughness, making it suitable for producing high-precision small to medium-sized castings.

- High Yield Rate: It features a low rejection rate and high material utilization, effectively reducing production costs.

2. Their Respective Disadvantages

- Disadvantages of Sand Casting

- Low Precision for Metal Castings: The precision is relatively low, often insufficient for high-precision parts, and may require subsequent secondary machining.

- Rough Casting Surface: The high roughness of the molds leads to comparatively rough surfaces on the castings.

- Low Yield Rate: It has a high rejection rate, low material utilization, and causes environmental pollution.

- Disadvantages of Investment Casting

- Higher Cost: Due to the complex process, which requires special materials and equipment, the cost is relatively high.

- Complex Process: The manufacturing process is relatively cumbersome, involving multiple steps and operations with high technical requirements.

-

Investment casting and sand casting also differ in their production processes. Investment casting involves heating the wax pattern to melt it, followed by cooling and solidification within the ceramic shell to form the casting. In contrast, sand casting requires placing the sand mold into a flask and then pouring molten metal into it, allowing it to cool and solidify to form the casting. The production cycle for investment casting is relatively longer, but it ensures higher dimensional accuracy and superior surface finish of the investment castings.

Summarizing the above advantages and disadvantages, we can draw the following conclusions. If the goal is to produce large, structurally complex castings without particularly stringent precision requirements, sand casting may be more suitable. If the goal is to produce small to medium-sized castings with high precision and superior surface quality, investment casting may be the better choice. However, please note that investment casting typically incurs higher costs compared to sand casting.

Of course, when selecting a casting process, it is essential to comprehensively consider factors such as cost, production cycle, casting precision, and surface quality to achieve optimal production efficiency and economic benefits. Therefore, the choice of casting method should take into account the actual requirements of the casting, production costs, and other relevant factors.