+86-0769 81582278

+86-0769 81582278 How to ensure the quality of lathe machining parts?

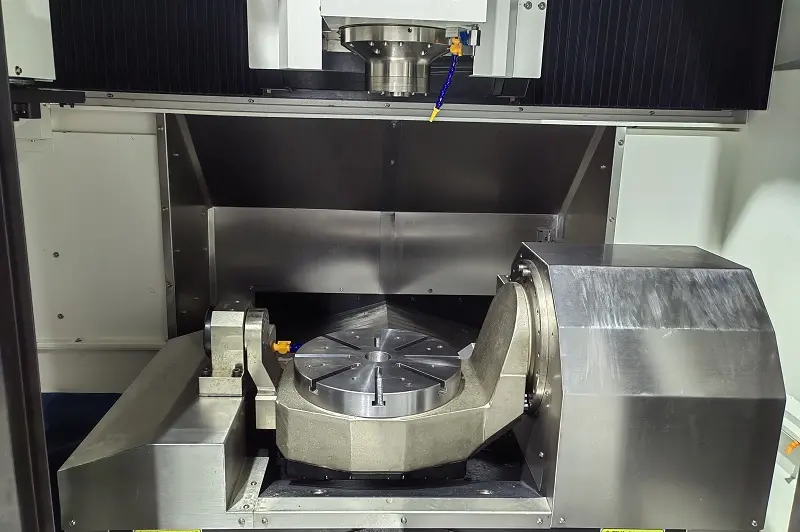

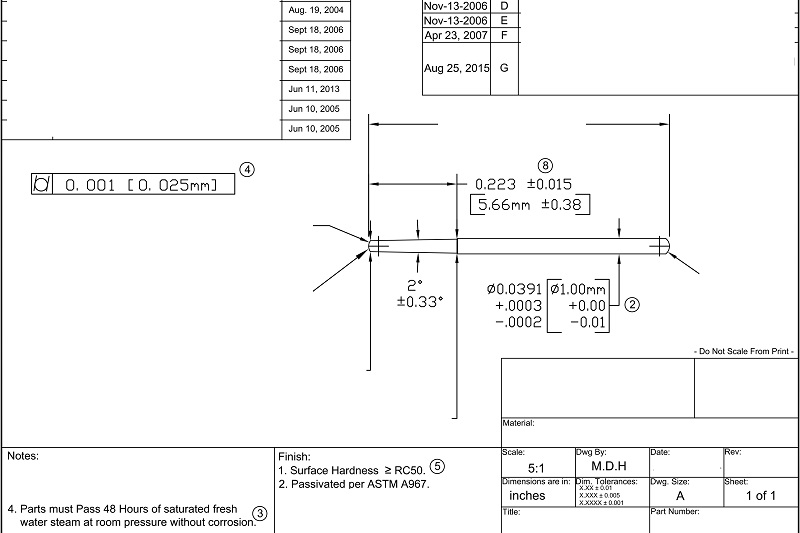

Regarding how to ensure quality in CNC metal machining, today I’ll use a metal product we recently manufactured as a case study for discussion. At first glance, the drawing may seem straightforward, but this part requires multiple processes—CNC turning, grinding, heat treatment, surface finishing, and more. Meeting the client’s specifications and dimensional tolerances at every stage is quite challenging. Below are the drawing and product photos. Based on our hands-on machining experience, we’ll analyze the key aspects in detail:

-

1. Machining Precision Control in Turning Operations

From the product drawing, we can see that due to the relatively small diameter of the product and the high tolerance requirement for the diameter, the specified tolerance of 1+0/-0.01mm is difficult to guarantee, as product deformation and tool wear during mass production can easily cause some products to exceed the tolerance limits. Therefore, we leave a 0.03mm allowance during the turning process and then uniformly perform another round of external cylindrical grinding to ensure all products fall within the qualified range.2. Control of Heat Treatment Deformation

This product has a relatively small diameter and considerable length, yet requires high hardness (≥HRC50), necessitating heat treatment to achieve the specified hardness. As is well known, the high-temperature process involved in heat treatment can easily cause product deformation. However, the usage requirements for this product stipulate that deformation must not exceed 0.025mm. To meet this specification, we ultimately customized specialized fixtures to secure the product during heat treatment, thereby effectively resolving the issue of heat treatment deformation.

3. Control of Surface Finishing

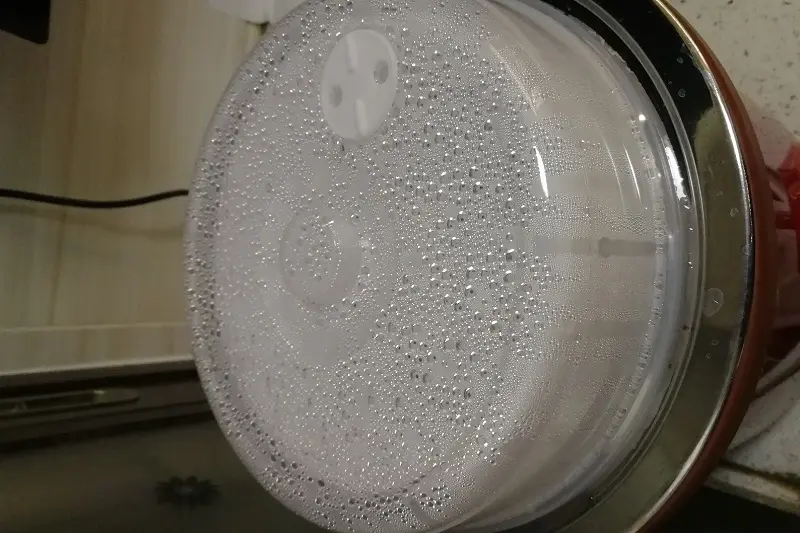

Based on the product's actual usage requirements, the material cannot be stainless steel and must instead be stainless iron, which makes it more prone to rust during use. To prevent rusting, a passivation surface finishing must be applied. However, how do we determine whether the passivation meets the customer's specifications? Clearly, a unified standard is necessary. Through testing under real-world conditions, the customer requires the product to pass a 48-hours of saturated fresh water steam at room pressure without corrosion test, which differs from standard salt spray tests and instead simulates the product's actual operating environment. After thorough discussions with the customer, we developed a similar testing device to verify compliance with their requirements. Please refer to the following image for a simplified view of the testing setup.

4. Final Quality Inspection and Control

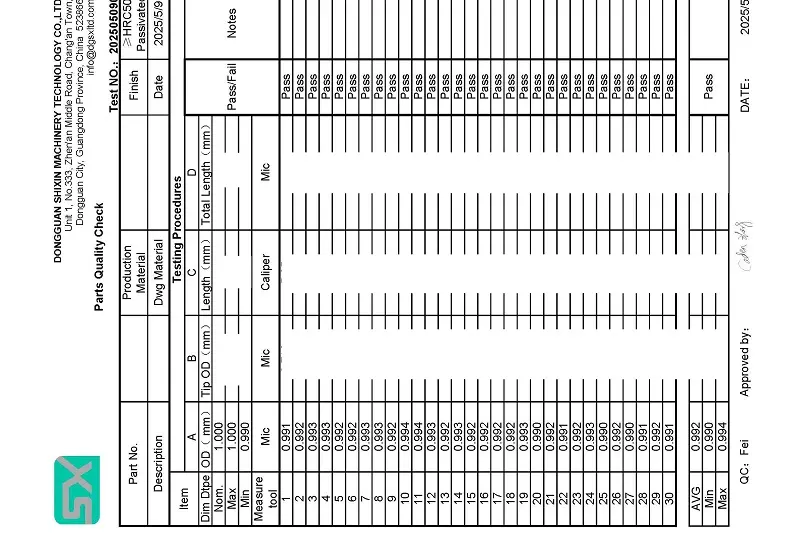

The purpose of quality inspection is to demonstrate that we strictly adhere to the drawings and product requirements throughout the processing and treatment stages, ensuring the final product meets all specifications. Therefore, even with rigorous control at each production step, we conduct a final inspection to guarantee that all shipped products are fully compliant. For instance, this includes the aforementioned 48-hours of saturated fresh water steam at room pressure without corrosion test, as well as random sampling inspections—such as the test report for 30 randomly selected components shown in the image below. Only after confirming that every production stage and the final results meet standards do we proceed with packaging and shipment, ensuring complete customer satisfaction.

-

In the CNC Machining Industry—whether forCNC milling machining or CNC turning machining—many products may appear straightforward at first glance based on drawings alone. However, a deeper analysis of each processing stage reveals numerous aspects worthy of discussion and collaboration. Critical considerations include machining techniques, heat treatment processes, surface treatments, and, most importantly, the interconnections and mutual influences among these factors, as each step or process can significantly impact the final product quality. We warmly welcome industry peers to engage in knowledge-sharing and collaborative problem-solving to drive continuous improvement in our field.