+86 180 0293 5268

+86 180 0293 5268

How to Manufacture Custom CNC Precision Components to a Higher Standard?

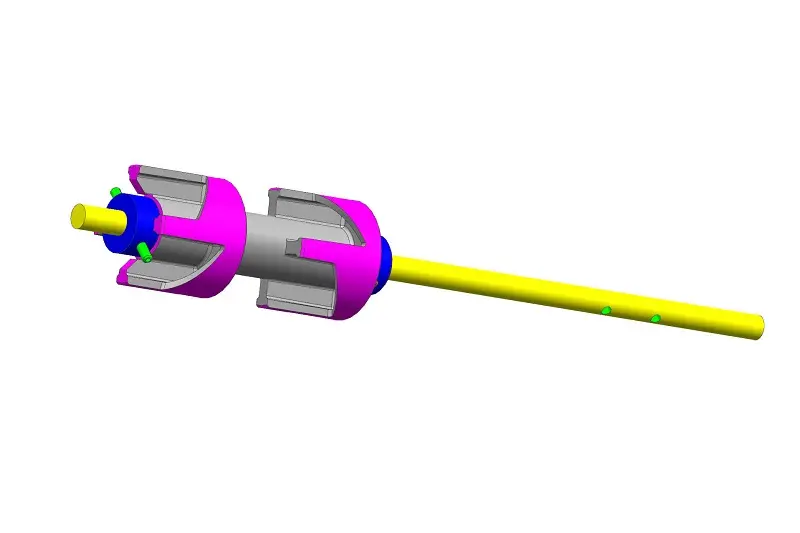

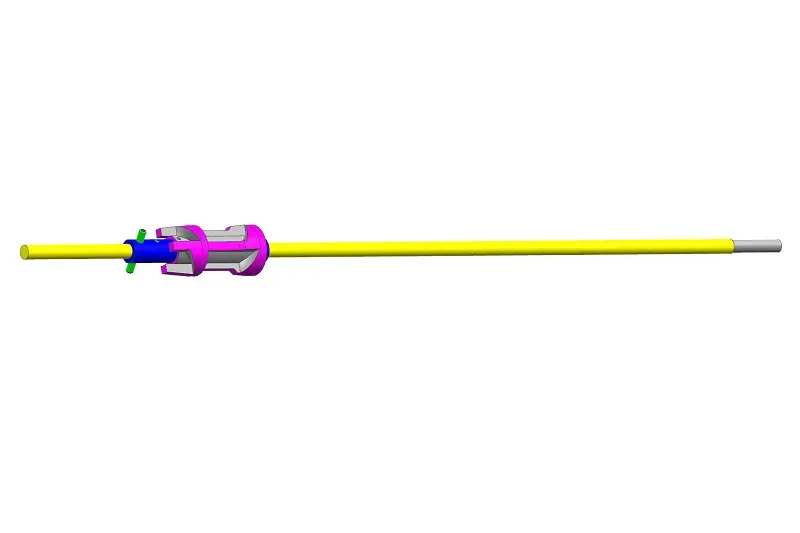

In precision CNC machining, where each component ultimately serves as part of a final assembly, it is essential to thoroughly understand the assembly methodology, functional purpose, and operational requirements of the end product before commencing machining operations. This foundational understanding allows for proper attention to critical tolerances and manufacturing processes, ensuring components are produced with assembly compatibility and optimal performance in mind. A case in point is our recent OEM project involving precision CNC machining parts and assembly, where the client provided comprehensive specifications regarding product application and functionality but limited tolerance requirements - necessitating our team to establish appropriate tolerance controls based on the component's actual operational demands. We will now proceed to discuss the following key aspects: auxiliary component selection, machining processes, cleaning and degreasing procedures, surface coating applications, and product quality inspection protocols.

-

1. Auxiliary component selection

As illustrated in the assembly diagram above, the installation requires cotter pins for secure fastening. Therefore, prior to machining the components, we must first carefully select auxiliary parts that strictly comply with specifications - only properly specified parts can ensure the assembled product meets operational requirements. After selecting appropriate auxiliary components, we implement stringent tolerance controls on the primary parts based on both assembly requirements and actual product application needs, thereby optimizing the quality and performance of the complete assembly unit.

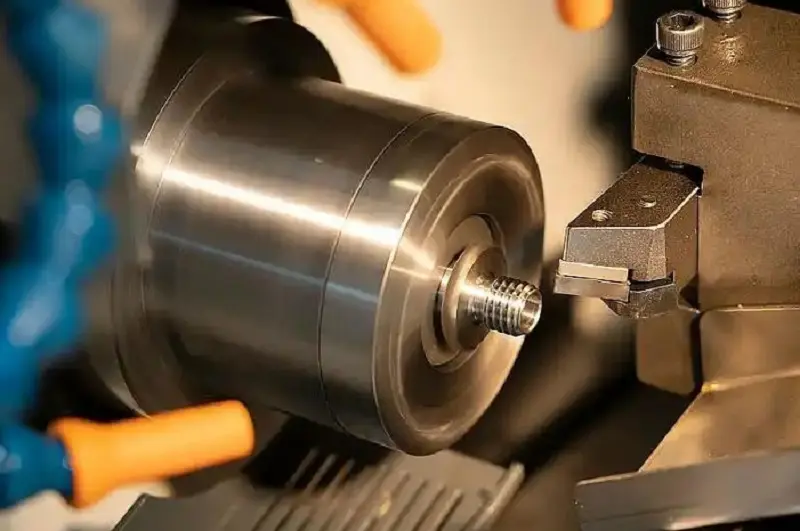

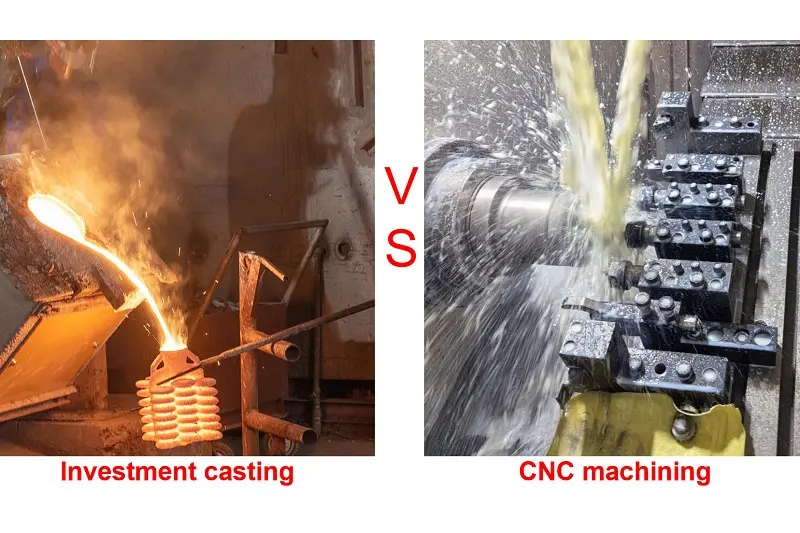

2. machining processes

When customers provide drawings with strict tolerance requirements, we must strictly adhere to these specifications during both machining and inspection processes to ensure the final product meets all operational requirements. For cases like ours where complete tolerance specifications aren't provided by the client, we first conduct thorough analysis of the product's functional requirements. Based on comprehensive understanding of assembly needs, we establish appropriate tolerance grades for each component before machining begins. Throughout production, we rigorously inspect each part's dimensions, form, and precision, implementing immediate corrective measures for any deviations to maintain compliance with quality standards. Furthermore, to guarantee post-assembly accuracy, we maintain exceptionally high machining precision to minimize tolerances, ensuring smooth and precise component integration throughout the assembly process.

3. cleaning and degreasing procedures

After machining is completed, all parts must undergo deburring, cleaning, and degreasing processes to remove oil contamination and metal chips. Even if the parts meet dimensional specifications, the presence of burrs or metal debris could potentially cause jamming or other issues during assembly. Therefore, implementing thorough deburring, cleaning, and degreasing procedures prior to assembly is essential to significantly reduce the risk of post-assembly failures and enhance the service life of the components. This preventive measure ensures smooth assembly operations and maintains long-term product reliability.

4. surface coating applications

Certain components require surface coating applications to enhance corrosion resistance, wear resistance, and other performance characteristics. The selection of high-quality coatings and advanced application techniques provides effective surface protection, preventing premature aging and damage during service. However, for components designated for specific operating environments where coating is unnecessary, we still implement temporary anti-corrosion treatments - particularly for materials with poor inherent rust resistance - to safeguard against oxidation during transportation and storage. This balanced approach ensures all parts maintain optimal condition throughout their lifecycle, from manufacturing to final application.

5. product quality inspection protocols

Upon completion of component assembly, comprehensive product quality inspection must be conducted, encompassing both dimensional verification of the assembled product and functional performance testing. Only after successfully passing all quality inspection criteria can the product be deemed qualified and meet our stringent quality standards. This critical quality assurance process ensures the final product's dimensional accuracy, proper functionality, and overall reliability before delivery to customers.

For us as a CNC precision machining manufacturer, the process extends far beyond simple CNC turning or milling operations. Even during machining, we frequently encounter challenges with complex part geometries where standard processes fail to meet required tolerances - necessitating adaptive machining strategies to achieve specification compliance. Additionally, material properties or machining methods may yield suboptimal surface finishes characterized by excessive roughness or scratches, common issues in CNC services that demand tailored solutions. While CNC technology has become ubiquitous in component manufacturing, its application still presents unexpected complications requiring vigilant problem-solving to produce quality CNC precision parts and assemblies. Of course, achieving manufacturing excellence involves numerous additional considerations, and we warmly invite collaboration to address these challenges. Please feel free to contact us at info@dgsxltd.com to discuss your specific requirements.