+86 180 0293 5268

+86 180 0293 5268

How to Understand Investment Casting?

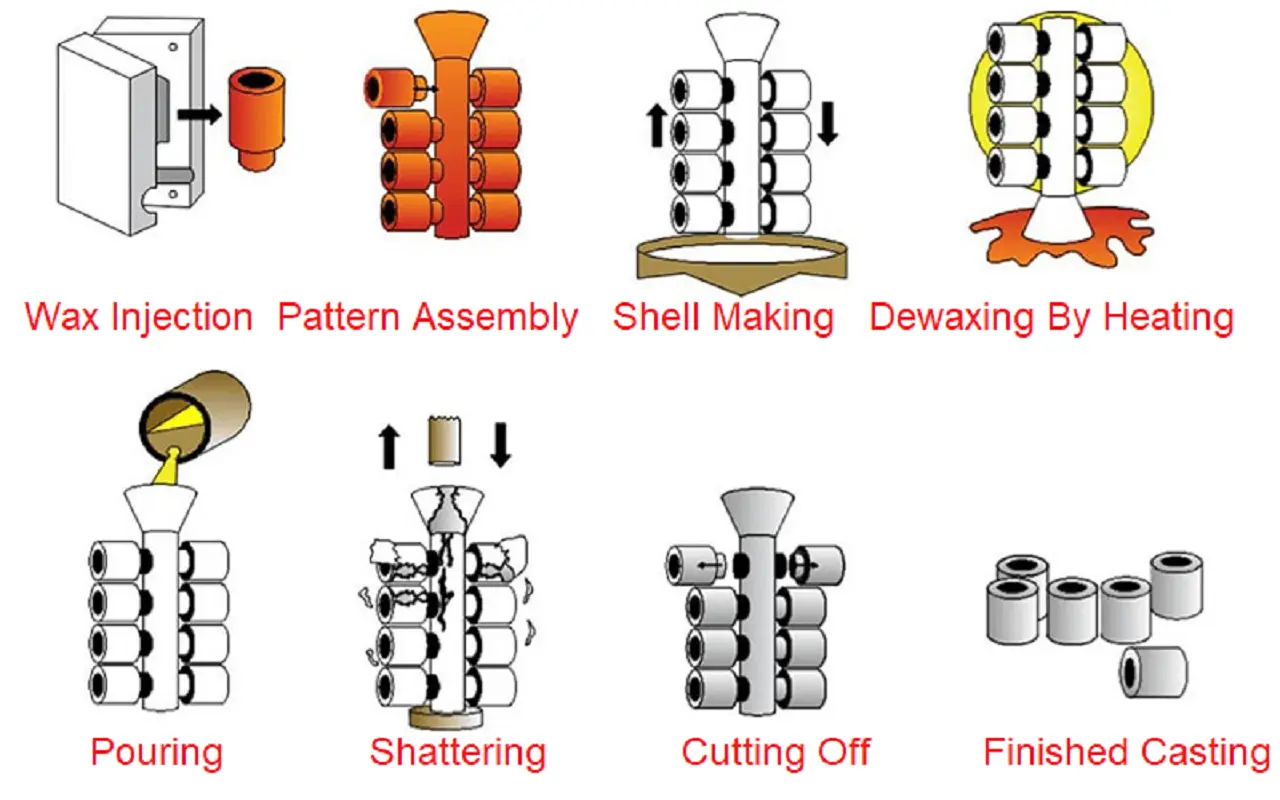

Investment casting, a sophisticated process that transforms wax patterns into precise metal components, can be classified into three main types based on the shell material used: silica sol casting, sodium silicate (water glass) casting, and composite casting. Also known as the "lost wax casting" process, this method involves multiple steps—including wax pattern creation, shell building, dewaxing, metal pouring, and post-casting treatment—to produce parts with exceptional dimensional accuracy and superior surface finish.

The core principle lies in applying successive layers of refractory material onto the wax pattern. Once hardened and dried, the wax is melted out to form a hollow ceramic shell. This shell is then fired and prepared for pouring molten metal, resulting in highly detailed and precise castings.

Now, let’s explore the complete workflow of investment casting in detail.

-

Investment casting is a method used to obtain high-precision metal casting parts through processes such as wax pattern creation, shell molding, dewaxing, pouring, and post-processing. This process requires not only skilled craftsmanship but also modern equipment and technology to ensure the high quality of investment castings.

2. Importance of Wax Pattern Production

In investment casting, wax patterns play a crucial role. They must accurately shape the cavity within the refractory shell while maintaining high dimensional precision and excellent surface finish to ensure the final quality of the castings. Additionally, the design and production of wax patterns should facilitate subsequent shell-making processes, thereby improving overall production efficiency.

3. Shell Making and Dewaxing

In investment casting, the wax pattern undergoes coating, sand stuccoing, and hardening to form a thin shell of 1–2 mm. However, to ensure sufficient shell strength, multiple coating cycles—typically six to seven layers or more—are required for different wax pattern shapes and structures. This results in a refractory shell with a final thickness exceeding 10 mm.

Next, to remove the wax pattern and form the casting cavity, a dewaxing process is performed. We employ steam dewaxing, which melts the wax and allows it to drain smoothly through the downward-facing sprue. The recovered wax is recycled for reuse, making the process both environmentally friendly and economical.

4. Pouring and Post-Processing

Before metal pouring, the shell must be placed in a sintering furnace and fired at temperatures above 950°C for approximately two hours. This step removes moisture, residual wax, and other impurities from the shell, enhancing its strength and ensuring cavity cleanliness.

After removal from the sintering furnace, the shell is immediately poured with molten metal at high temperatures (typically around 1050°C). At this stage, the slower cooling rate and relatively high fluidity of the molten metal within the shell enable precise replication of the cavity shape, thereby improving casting accuracy.

After pouring and cooling, the castings undergo a series of post-processing steps to meet customer requirements for appearance and performance. These steps include shell removal, shot blasting, gate cutting, grinding, weld repair, passivation, and heat treatment. Through multiple inspections, defective castings are identified and repaired to ensure the final product quality.

After gaining a comprehensive understanding of the investment casting process, it is crucial to recognize the common defects that may arise during production and how to mitigate or prevent them. Defects in investment castings can be categorized into surface and internal flaws, as well as dimensional and roughness deviations. Surface and internal defects include issues such as incomplete filling, cold shuts, shrinkage porosity, gas pores, slag inclusions, hot tearing, and cold cracking, while dimensional and roughness deviations are primarily manifested as elongation and deformation of the castings.

The occurrence of these defects is influenced by multiple factors, such as the pouring temperature of the molten alloy, the sintering temperature and preparation process of the ceramic shell, and the design of the gating system and casting structure. To address different types of defects, it is essential to analyze their specific causes and implement corresponding preventive and corrective measures. For example, to mitigate incomplete filling, it may be necessary to increase the pouring temperature and shell temperature to ensure adequate fluidity of the molten metal. Alternatively, adjustments can be made to the wall thickness of the casting or the design of the gating system. Other measures include thorough sintering of the shell to improve its permeability, controlling the pouring speed, and ensuring sufficient molten metal volume. Through these targeted approaches, defects in precision casting components can be effectively reduced or eliminated, thereby enhancing product quality.