+86 180 0293 5268

+86 180 0293 5268

Is stainless steel casting expensive?

As a high-precision and high-quality manufacturing method, stainless steel investment casting is widely used across various industrial sectors. However, its cost is relatively higher compared to traditional casting processes. The cost of stainless steel castings is influenced by multiple factors, including raw material costs, process complexity (casting costs), post-casting processing expenses, market supply and demand, and other related expenditures. In the following sections, we will analyze the cost of stainless steel castings from several perspectives, hoping to provide some useful insights.

-

1. Impact of Raw Material Costs

The primary raw material for stainless steel castings is stainless steel (such as commonly used grades like SUS 304 and SUS 316). Its price is influenced by factors such as fluctuations in the international market and domestic supply-demand dynamics. An increase in raw material prices directly raises the cost of castings, thereby affecting their final price. However, this impact of raw material costs does not directly determine whether stainless steel castings are expensive or not, as even when alternative processing methods are used, the cost of the same raw material is inherently included.

2. Impact of Casting Costs

The investment casting process involves multiple steps, including mold production, melting, pouring, cooling, and others. The cost of these processes depends on factors such as the complexity of the design, the sophistication of the equipment, and the skill level of the operators. Complex product structures and demanding technical requirements necessitate higher levels of expertise and more advanced equipment, leading to an increase in product costs. Furthermore, even for the same process, the type of raw materials used by different manufacturers can affect the price. For instance, some foundries may use green sand, while others might use resin sand, with green sand being the less expensive option.

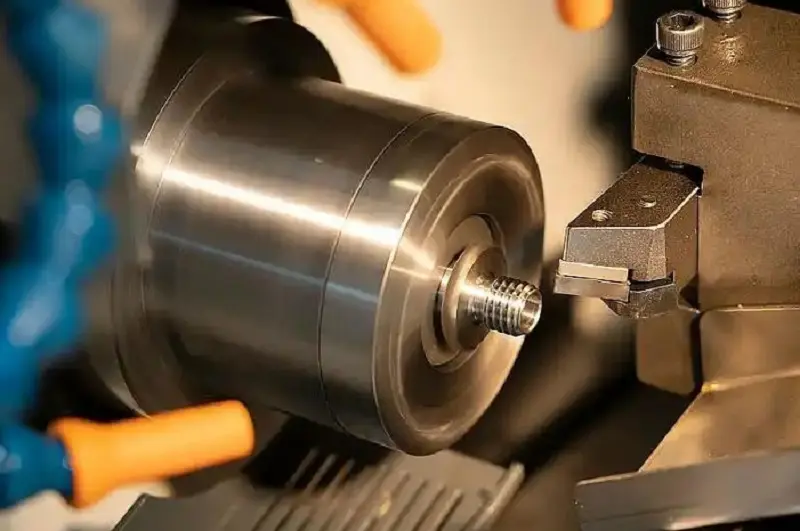

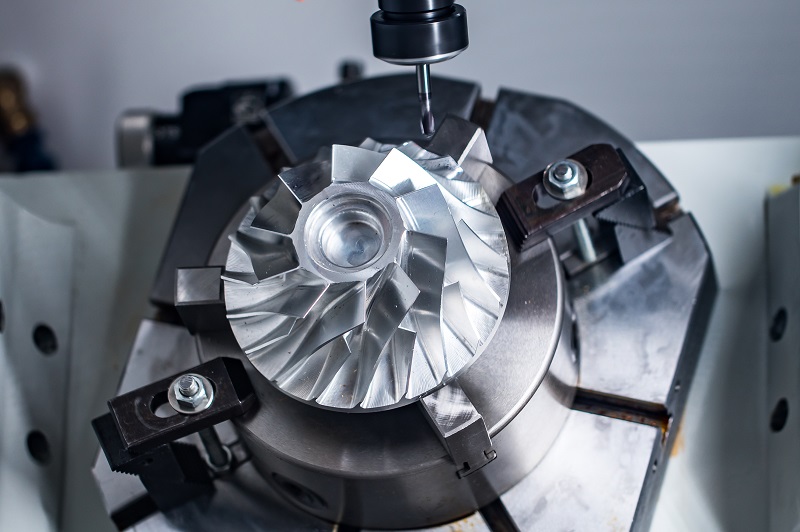

However, when compared to precision CNC machining, which can also produce complex shapes, investment casting demonstrates significant advantages for parts with intricate geometries. This is because machining highly complex structures via CNC involves substantially higher equipment costs and lower production efficiency.

3. Impact of Post-Casting Machining Costs

For high-demand stainless steel investment castings, precision CNC machining is often required after casting to meet specific application requirements, which incurs additional processing costs. CNC machining costs are typically calculated based on the complexity of the process—the greater the complexity, the higher the cost. Additionally, order quantity is a significant factor influencing machining costs. Moreover, if the foundry lacks in-house precision CNC machining capabilities, outsourcing becomes necessary, further increasing the overall cost of the castings.

At Dongguan SX, we have our own precision CNC machining workshop and a professional technical team. We analyze the characteristics of actual cast parts to determine the most optimal CNC machining approach, ensuring both quality (such as precision) and improved processing efficiency. With our unified quality control system, we guarantee the final qualification rate of stainless steel investment castings.

4. Impact of Market Supply and Demand

The development trends of the stainless steel casting market also influence its costs. With the continuous upgrading of industrial sectors and technological advancements, the market demand for stainless steel castings continues to grow. Factors such as technological optimization and changes in the competitive landscape of the industry will also impact market prices.

5. Impact of Other Costs

Factors such as fuel, electricity, and labor costs also influence the production cost of castings. However, the extent of this impact varies by region. These elements can consequently affect the overall production cost of stainless steel castings.

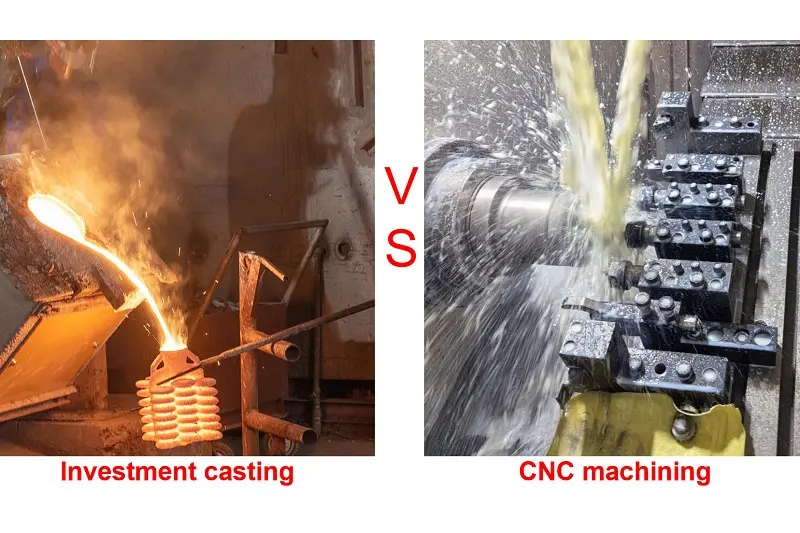

"Is stainless steel investment casting expensive?" This is a complex and variable question, influenced by many factors. However, we can provide a simple comparative summary between investment casting and precision CNC machining.

If most features of a part have high requirements and necessitate subsequent CNC machining, it is generally more cost-effective to opt for full CNC machining from the start. This is because performing full CNC machining after investment casting tends to be relatively more expensive.

On the other hand, for parts with complex geometries but only minor or no extremely high dimensional requirements (requiring little to no post-casting CNC machining), investment casting may be considered, as it can significantly reduce costs. Additionally, for very low quantities (such as just a few prototypes), CNC machining is typically the preferred option due to its lower cost and higher efficiency for small batches.

Therefore, when evaluating whether stainless steel investment casting is expensive, it should be compared against other manufacturing processes that can meet the requirements. If investment casting offers a lower cost while fulfilling all specifications, then it is the process of choice—and relatively speaking, not expensive.

We welcome further discussion at info@dgsxltd.com.