+86 180 0293 5268

+86 180 0293 5268

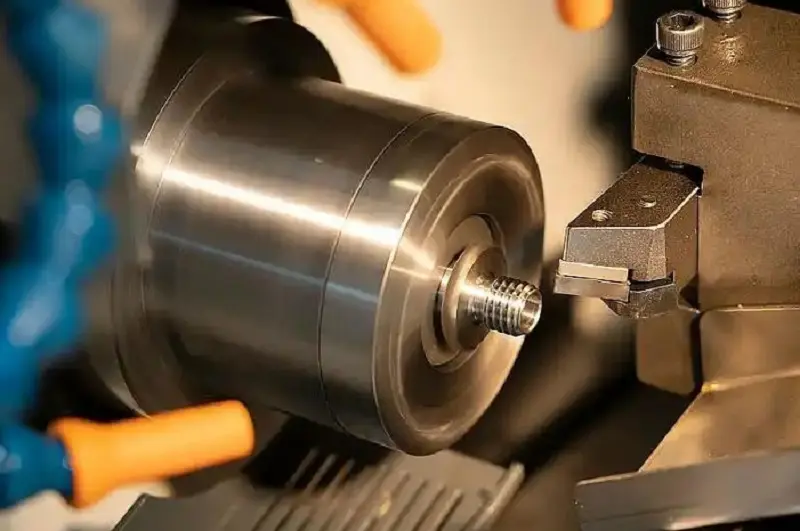

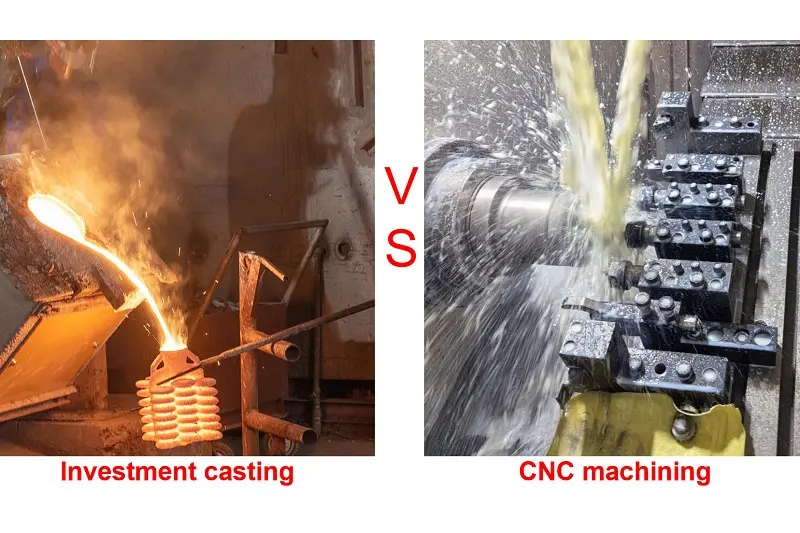

We provide CNC turning, CNC milling, CNC turn-mill compound machining, and metal investment casting services.

Dongguan SX is a full-service manufacturing partner offering one-stop precision machining solutions for global clients. Our comprehensive capabilities span CNC machining (including turning, milling, and turn-mill combined operations), metal investment casting (specializing in stainless steel, carbon steel, and hybrid casting-machining processes), heat treatment, surface finishing, and final assembly services. With extensive industry expertise, we distinguish ourselves through:

-

1. Advantages of Integrated Manufacturing Technology

l Full-Process Chain Coverage

From investment casting to CNC precision machining, followed by surface treatment and assembly, we provide one-stop production—eliminating intermediate handling errors and ensuring higher delivery consistency.l Material & Process Synergy Optimization

Our investment casting allows for custom special alloys, combined with CNC post-processing, enabling near-net-shape forming + precision machining of high-difficulty materials—reducing material waste significantly.

l Turn-Mill Hybrid & Multi-Axis Machining

Complete multi-surface machining in a single setup, avoiding repositioning errors—ideal for precision finishing of investment casted parts.

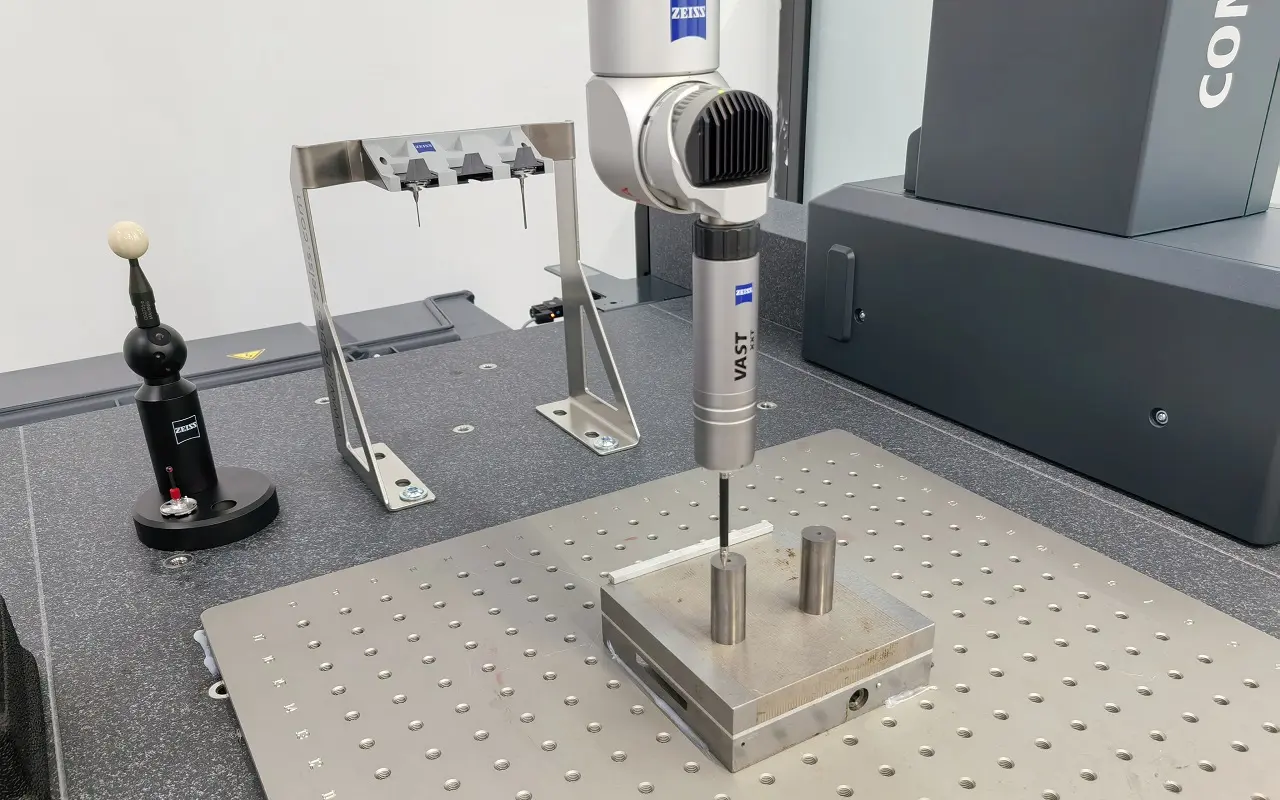

2. Quality & Efficiency Advantages

l Integrated Dimensional Accuracy & Surface Finishing

By combining investment casting with CNC precision machining, we achieve high-accuracy components ready for direct post-processing (e.g., polishing, coating, etc.), ensuring superior surface quality and tight tolerances.

l Rapid Prototyping to Mass Production

Our short lead time for investment casting molds, paired with CNC rapid prototyping, accelerates the entire process from design validation to full-scale production, reducing time-to-market.

3. Industry Solution Advantages

l Expertise in High-Complexity Components

We specialize in manufacturing challenging high-precision parts through complex investment casting followed by multi-axis CNC machining, delivering geometrically intricate components with tight tolerances.

l Cost Optimization Capabilities

Our investment casting minimizes material waste through near-net-shape forming, while CNC-optimized toolpaths further reduce machining costs – significantly lowering expenses for high-value metals.

4. Differentiated Customer Service

l Proactive Technical Support

We provide Design for Manufacturing (DFM) guidance from the early design stage, optimizing part structures to simplify casting and machining processes while maintaining quality.

l Flexible Production Response

Our adaptable manufacturing system accommodates small-batch, high-mix production, with rapid adjustments to CNC programming and casting parameters to meet diverse requirements.

Our Full-Service Solution: Investment Casting + CNC Machining + Post-Processing & Assembly – One-Stop Complex Part Manufacturing.

We specialize in:

✔ High-Precision

Turn-Mill Combined Machining

✔ Expertise in

Special Alloys & Challenging Materials

✔ Rapid Prototyping

to Mass Production Transition

✔ Cost Optimization

& Efficiency Enhancement

Your Trusted Partner for Precision

Components.

Contact us today at info@dgsxltd.com to discuss your project requirements!