+86 180 0293 5268

+86 180 0293 5268

What are the advantages of aluminum alloy in precision CNC machining?

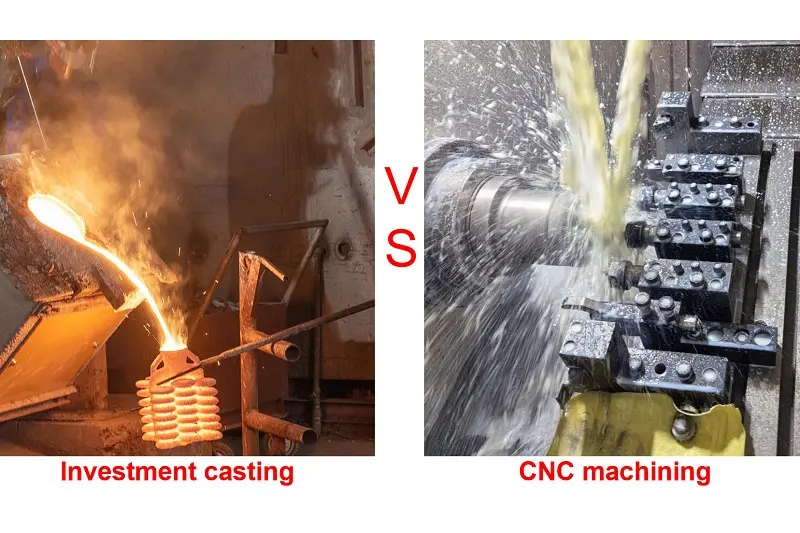

In the field of precision CNC machining, material selection directly influences processing efficiency and product quality. Aluminum alloy stands out in CNC machining due to its unique combination of properties, making it one of the preferred materials across various industries such as aerospace, consumer electronics, and automotive manufacturing—rightly earning it the title of the "Lightweight Artisan" of modern manufacturing. As a high-precision forming technology, CNC machining of aluminum alloy demonstrates broad application value in numerous fields, leveraging its distinct advantages. It integrates high-quality aluminum alloy materials with advanced CNC technology, solidifying its critical role in machining processes. Next, let's explore some of the key advantages of aluminum alloy in precision CNC machining.

-

1. Excellent Specific Strength and Lightweight Nature

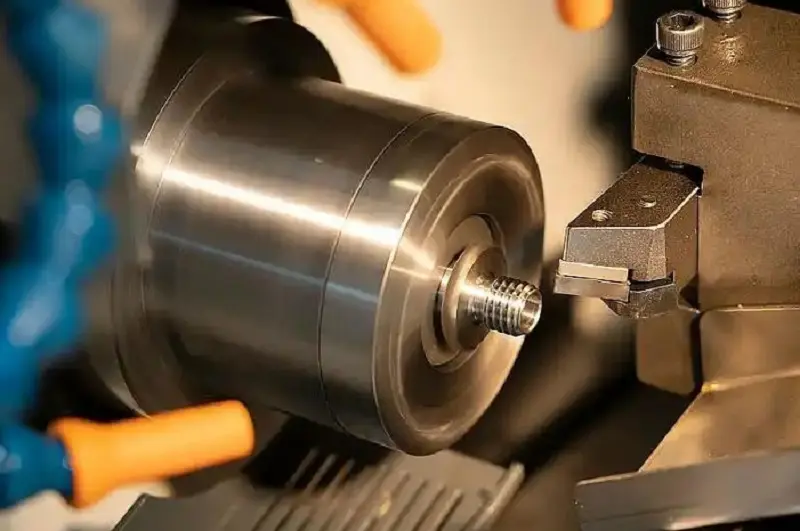

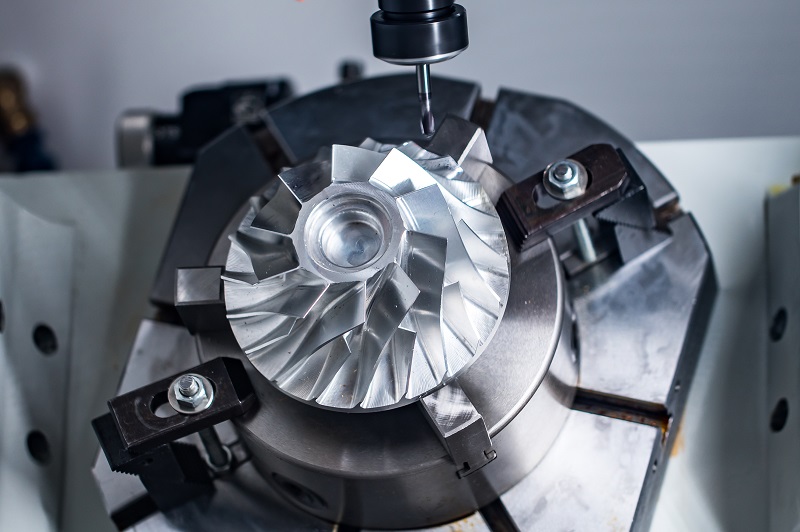

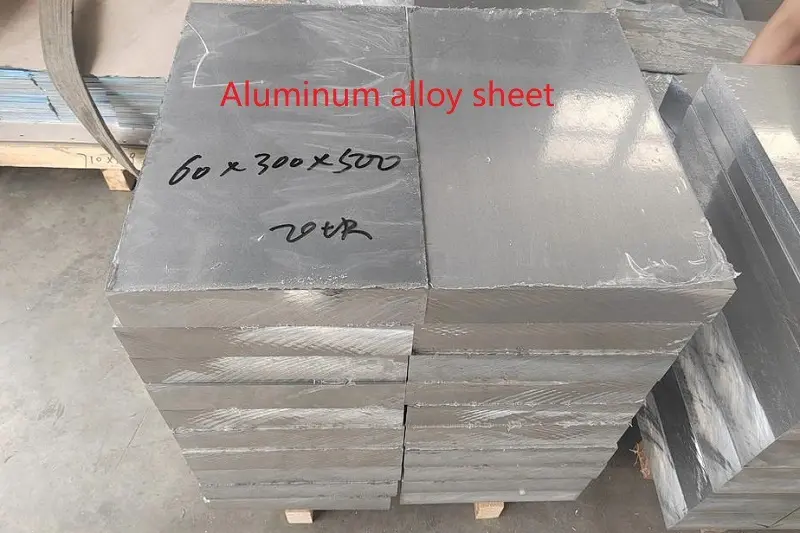

Aluminum alloy has a density of only about one-third that of steel, yet it can achieve remarkable strength through alloying and heat treatment. This allows machined parts to meet structural requirements while significantly reducing overall weight—essential for products that prioritize energy efficiency, speed, or portability. Whether in aircraft frames or smartphone chassis, the combination of lightness and strength is made possible by aluminum alloy. Both CNC turning and milling processes preserve these inherent characteristics of aluminum. Common grades such as 6061 and 6063, as well as higher-hardness series like 7075, can be effectively machined by selecting appropriate tool parameters and cutting techniques. This versatility enables aluminum alloy to meet demands ranging from general structural components to high-performance parts.2. Outstanding Machinability

Compared to many other metals, aluminum alloy is relatively soft, offers low cutting resistance, and causes mild tool wear. In high-speed CNC machining, aluminum allows for higher spindle speeds and feed rates, which not only significantly improves machining efficiency and shortens production cycles but also yields smoother surface finishes. This reduces the need for additional finishing processes, thereby lowering overall costs. Moreover, CNC-machined aluminum parts typically exhibit high surface quality with uniform and fine tool marks, providing an excellent foundation for subsequent surface treatments. Whether anodizing for enhanced corrosion resistance and diverse colors, or sandblasting and polishing for special textures, the flat and clean surface achieved through CNC machining ensures more uniform and ideal finishing results.3. Good Thermal and Electrical Conductivity

Excellent thermal conductivity helps dissipate heat quickly during cutting, minimizing precision errors caused by thermal deformation and ensuring high stability and dimensional consistency in CNC machining. Its electrical conductivity also facilitates subsequent surface treatments such as anodizing, which not only provides a wide range of colors and superior wear and corrosion resistance but also enhances surface hardness.4. High Production Efficiency and Controllability

Once machining programs are validated and optimized, CNC machines can operate continuously and stably over long periods, making them suitable for batch production. Automated machining reduces intermediate steps and shortens the production cycle for individual parts. Additionally, the entire machining process is parameter-controlled and traceable, which aids in quality management and analysis, ensuring stable and efficient production operations.

Furthermore, aluminum alloy CNC parts boast exceptional material stability, corrosion resistance, and outstanding recyclability, aligning with the principles of green manufacturing. From prototyping to mass production, and from complex cavities to precision thin-walled components, CNC machining centers work seamlessly with aluminum alloy, accurately interpreting design intentions through digital toolpaths.

Aluminum alloy integrates numerous advantages in CNC machining, including lightweight yet high strength, excellent machinability, high stability, surface treatment potential, and cost-effectiveness. It is not only an ideal material for efficient machine tool operation but also a reliable medium for engineers to achieve lightweight, precise, and intelligent designs, consistently advancing high-end manufacturing to higher levels.

On another note, growing environmental awareness is driving industries to seek greener and more sustainable solutions. Compared to traditional mechanical processing methods, aluminum alloy CNC machining not only significantly reduces raw material consumption but also enables the recycling of waste materials, aligning with current societal development trends. For enterprises, this represents not only a cost-saving measure but also a demonstration of their commitment to social responsibility.