+86 180 0293 5268

+86 180 0293 5268

What are titanium screws used for?

Titanium screws are widely utilized across various advanced industries due to their unique properties, such as low density, high strength, excellent corrosion resistance, superior heat and cryogenic resistance, non-magnetic characteristics, and non-toxicity.

Compared to traditional stainless steel screws, titanium screws demonstrate greater flexibility and oxidation resistance, making them more suitable for a broader range of specialized applications. Particularly in high-pressure environments, titanium screws exhibit significantly better compressive strength than ordinary stainless steel screws.

In many specialized fields, titanium alloy is often chosen as a critical material, with titanium bolt serving as essential connecting components that play an indispensable role.

Now, let's explore the industries where titanium screws are extensively used:-

1. Transportation Industry

Bicycles

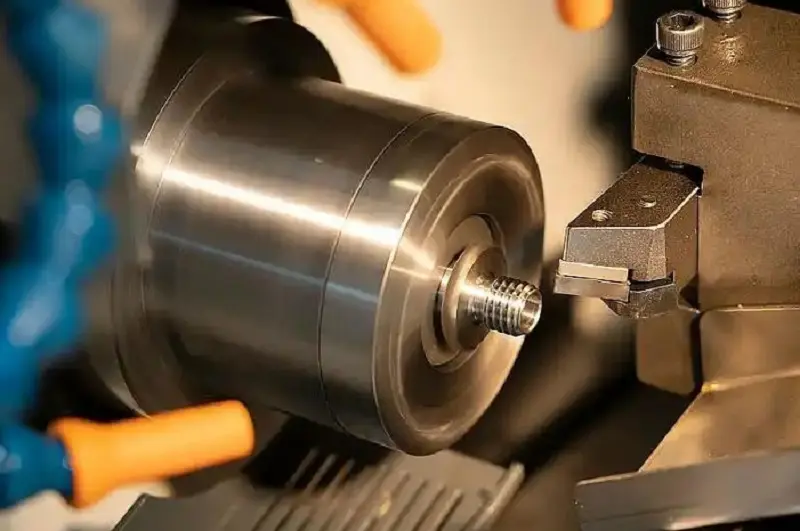

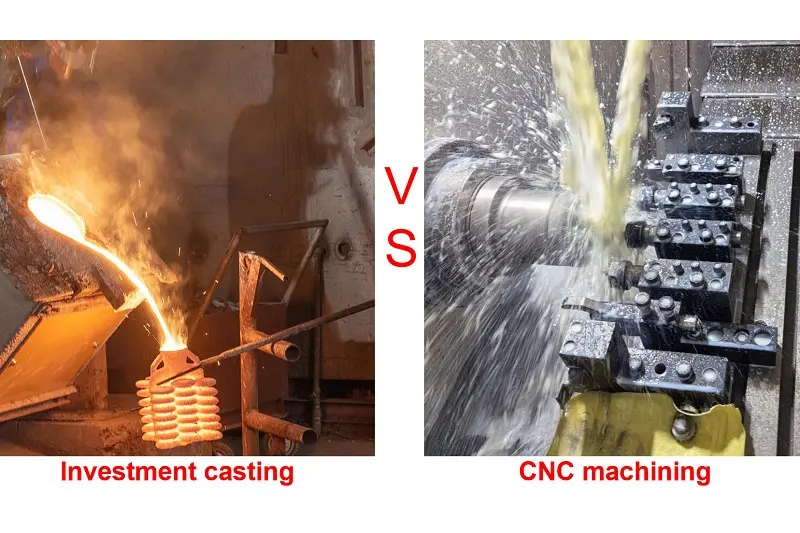

Titanium screws are commonly used in high-end bicycle assembly due to their lightweight and corrosion-resistant properties, which help reduce overall weight and enhance durability. Additionally, titanium screws can be customized via CNC machining to produce a variety of personalized titanium CNC components.Automotive

In automotive manufacturing, especially for critical components such as automotive motors, titanium screws are widely used for their high strength and heat resistance.2. Aerospace Industry

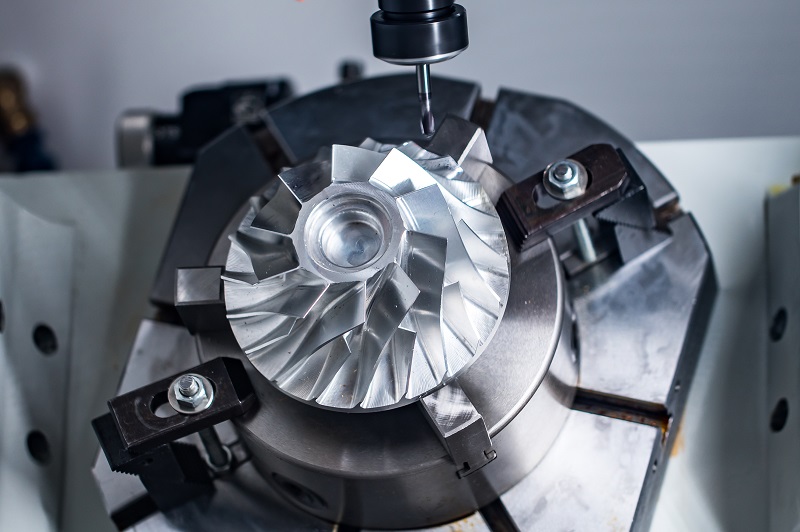

The lightweight and high-strength characteristics of titanium screws make them ideal fasteners for aircraft, rockets, missiles, and other aerospace applications. Replacing steel screws of comparable strength with titanium alloy screws significantly contributes to weight reduction in aerospace vehicles. Moreover, titanium alloy’s excellent elasticity and non-magnetic properties play a crucial role in preventing screw loosening and mitigating electromagnetic interference. Titanium alloy can also be processed into various types of components through methods such as CNC milling, making it widely applicable in the aerospace sector.3. Medical Field

Titanium screws exhibit excellent biocompatibility and do not react with human tissues, making them widely used in medical devices such as artificial joints, dental implants, and ophthalmic implants. Additionally, titanium screws are utilized in the fixation and treatment of clinical fractures and dislocations.4. Marine Engineering and Chemical Industries

In marine and chemical environments, titanium alloy fasteners effectively resist seawater corrosion, extend equipment service life, and facilitate maintenance. They are commonly used as fasteners in structures such as ships and offshore platforms.5. Energy Sector

Titanium screws are applied in condensers at power stations and are also used in manufacturing other energy production-related equipment. In the development of nuclear power, titanium screws have become indispensable metal components. During the construction of nuclear reactors, numerous pipelines and related parts require substantial amounts of titanium and titanium alloy metals, with titanium alloy screws being an integral part of these applications.6. Food Processing Industry

The non-toxic nature and corrosion resistance of titanium screws make them suitable for manufacturing food processing machinery, ensuring hygiene and safety in food production.7. Sports and Leisure Equipment

In sports equipment such as golf clubs, titanium screws are widely used for their lightweight and high-strength properties, contributing to improved performance and extended service life of the equipment.8. Other Fields

Titanium screws are also utilized across various industries, including electroplating, aluminum anodizing, watchmaking, pharmaceuticals, aquaculture, electronic hardware, plastics, and more. For example, in electronic devices, steel screws are magnetic and require demagnetization treatment; otherwise, they can become magnetized under electromagnetic fields, potentially interfering with network signals. Titanium screws effectively resolve this issue.

In summary, titanium screws play a vital role in numerous industries due to their exceptional properties. With ongoing technological advancements and cost reductions, the application scope of titanium screws continues to expand. It is not only titanium alloy screws but also other titanium components—such as diverse titanium parts manufactured through CNC turning and CNC milling—that serve critical functions across these industries. With their outstanding overall performance, titanium alloy fasteners and other titanium parts play essential roles in both specialized fields and civilian applications. Despite the relatively high cost of titanium alloy, progress in production techniques for titanium materials will undoubtedly promote the wider adoption of titanium components in civilian sectors.