+86 180 0293 5268

+86 180 0293 5268

What is a 316 stainless steel casting?

A 316 stainless steel casting is a component manufactured using the casting process with stainless steel 316 as the raw material. Since stainless steel 316 offers properties such as corrosion resistance, high-temperature resistance, and high strength, 316 stainless steel castings inherently share these characteristics. Consequently, they are commonly employed in demanding environments requiring corrosion resistance, high temperature, and high pressure, especially in fields like marine engineering, chemical processing equipment, and medical devices. They play a critical role by maintaining performance over long periods in humid and corrosive conditions without failure.

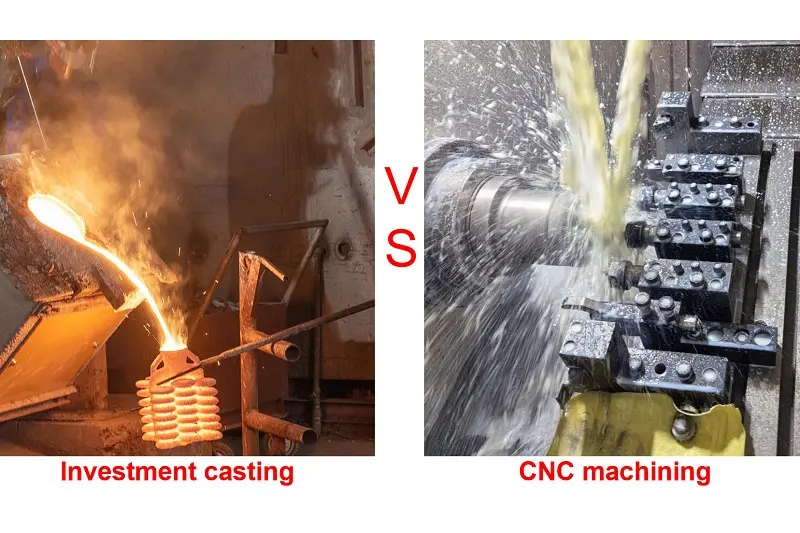

Typically, 316 stainless steel castings are produced via sand casting or investment casting. Investment casting, which involves wax pattern molding, shell mold preparation, and high-temperature pouring, achieves high precision and superior surface finish. In contrast, sand casting generally results in lower precision and poorer surface finish, sometimes with issues like shrinkage porosity. Therefore, investment casting is often used for small to medium-sized parts with higher requirements, while sand casting may be considered for larger parts with less stringent specifications to reduce costs.

Next, let’s analyze some specific applications and features of 316 stainless steel castings.

-

1. Applications of 316 Stainless Steel Castings

l Chemical Equipment

316 castings can be used to manufacture components for chemical equipment, such as reactors, heat exchangers, and valves. They are capable of withstanding various corrosive media and high-temperature working conditions.

l Food Processing

As 316 stainless steel complies with food safety standards, 316 stainless steel castings can be used to produce components for food processing equipment, including conveyor belts, pumps, and valves.

l Medical Devices

316 stainless steel offers excellent biocompatibility and corrosion resistance, making 316 stainless steel castings suitable for manufacturing components in medical devices, such as surgical instruments and dental tools.

l Aerospace

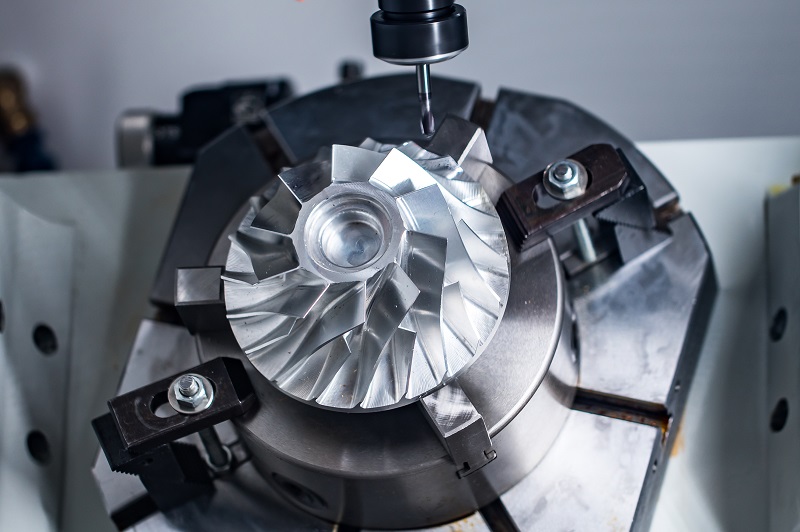

With its good biocompatibility and corrosion resistance, 316 stainless steel can be utilized to produce components for the aerospace industry, including engine parts and aircraft structural components.

l Marine Engineering

The marine environment contains high levels of salt, with chloride ions being a major cause of metal corrosion. 316 stainless steel castings effectively resist seawater erosion, extending the service life of equipment and structures while reducing maintenance costs. They are applicable in seawater desalination equipment, ship propellers, critical fasteners and structural components for offshore platforms, as well as seawater pipeline systems.

2. Characteristics of 316 Stainless Steel Castings

l Corrosion Resistance

316 stainless steel offers excellent corrosion resistance, maintaining stable performance in various corrosive environments, making it suitable for components operating under harsh conditions.

l Heat Resistance

316 stainless steel also possesses good heat resistance, maintaining reliable performance at high temperatures, which makes it suitable for manufacturing components that need to withstand elevated temperatures.

l Mechanical Properties

316 stainless steel castings exhibit outstanding mechanical properties, such as high strength, high hardness, good wear resistance, and impact resistance, meeting the demands of various complex working conditions and machining requirements.

l Machinability

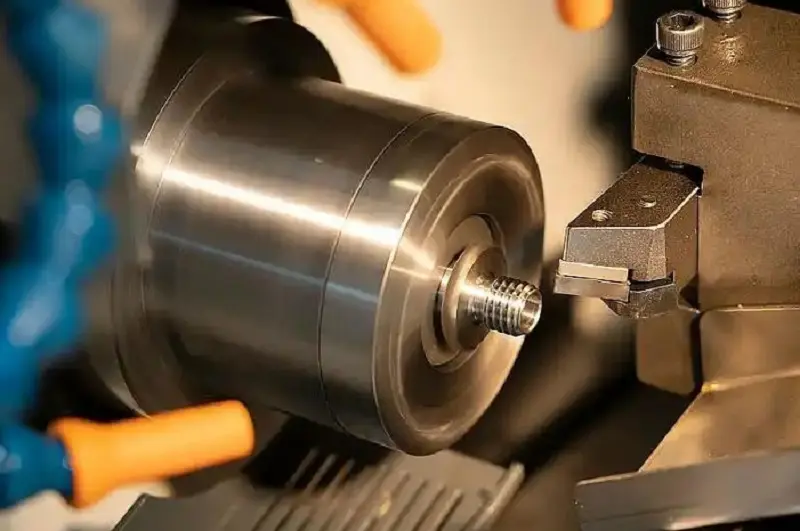

316 stainless steel castings also offer good machinability, allowing for mechanical processing operations such as turning, milling, planing, and grinding, facilitating the production of diverse components and products.

316 stainless steel castings offer numerous advantages. They exhibit excellent corrosion resistance, capable of withstanding oxidation as well as acidic and saline media. They also possess favorable mechanical properties, including high strength, good toughness, and fatigue resistance. Additionally, 316 stainless steel castings demonstrate good machinability, allowing for processes such as cutting, welding, and cold forming.

However, 316 stainless steel castings also have certain limitations. Firstly, due to the relatively high cost of 316 stainless steel, the production cost of investment castings is correspondingly elevated. Secondly, the high thermal expansion coefficient of 316 stainless steel can lead to deformation or cracking of castings under high-temperature conditions. Furthermore, defects such as porosity and shrinkage may occur during the solidification process of 316 stainless steel castings, which can affect their quality.

In summary, 316 stainless steel castings are widely used mechanical components with broad application areas. Their superior performance meets the demands of various complex working conditions and machining requirements, particularly excelling in specialized environments. They provide robust support for the development of diverse industries.