+86 180 0293 5268

+86 180 0293 5268

Why are titanium alloys difficult to CNC machining?

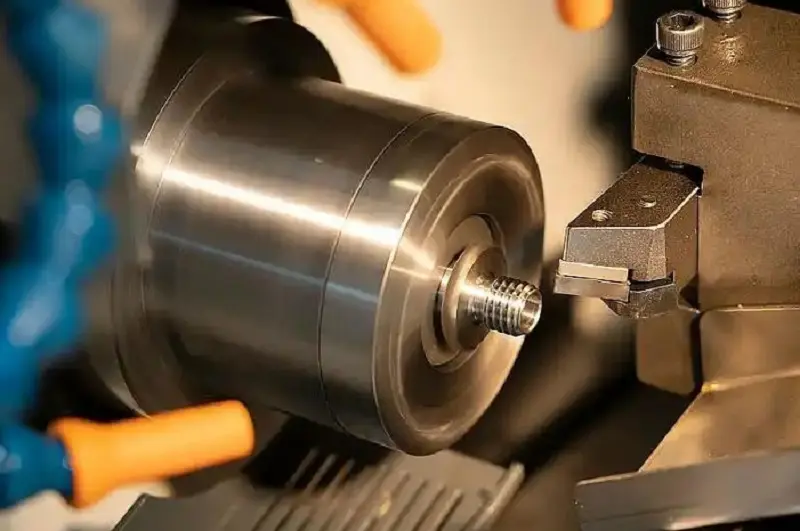

In the CNC machining industry, titanium alloy is recognized as a high-performance material due to its high strength, low density, excellent thermal stability, and corrosion resistance. In recent years, the use of titanium alloy components, such as titanium screws, has been increasing annually. However, titanium alloy is considered a difficult-to-machine material, primarily due to the complex physical phenomena during machining, where thermal effects, elastic deformation, and work hardening interweave, leading to short tool life and challenges in ensuring part accuracy. Particularly in CNC machining, processing titanium alloy poses significant challenges in tool selection, path planning, and parameter matching. Inappropriate machining methods can exacerbate tool wear, generate excessive heat and stress deformation, and ultimately compromise part precision. Therefore, understanding the difficult-to-machine characteristics of titanium alloy, selecting appropriate tools, optimizing cutting parameters, and applying advanced programming techniques are key to addressing these challenges. Below, we analyze in detail why titanium alloy is so difficult to machine with CNC from the following perspectives.

-

1. Thermal Effects: Heat Accumulation Leading to Multiple Machining Challenges

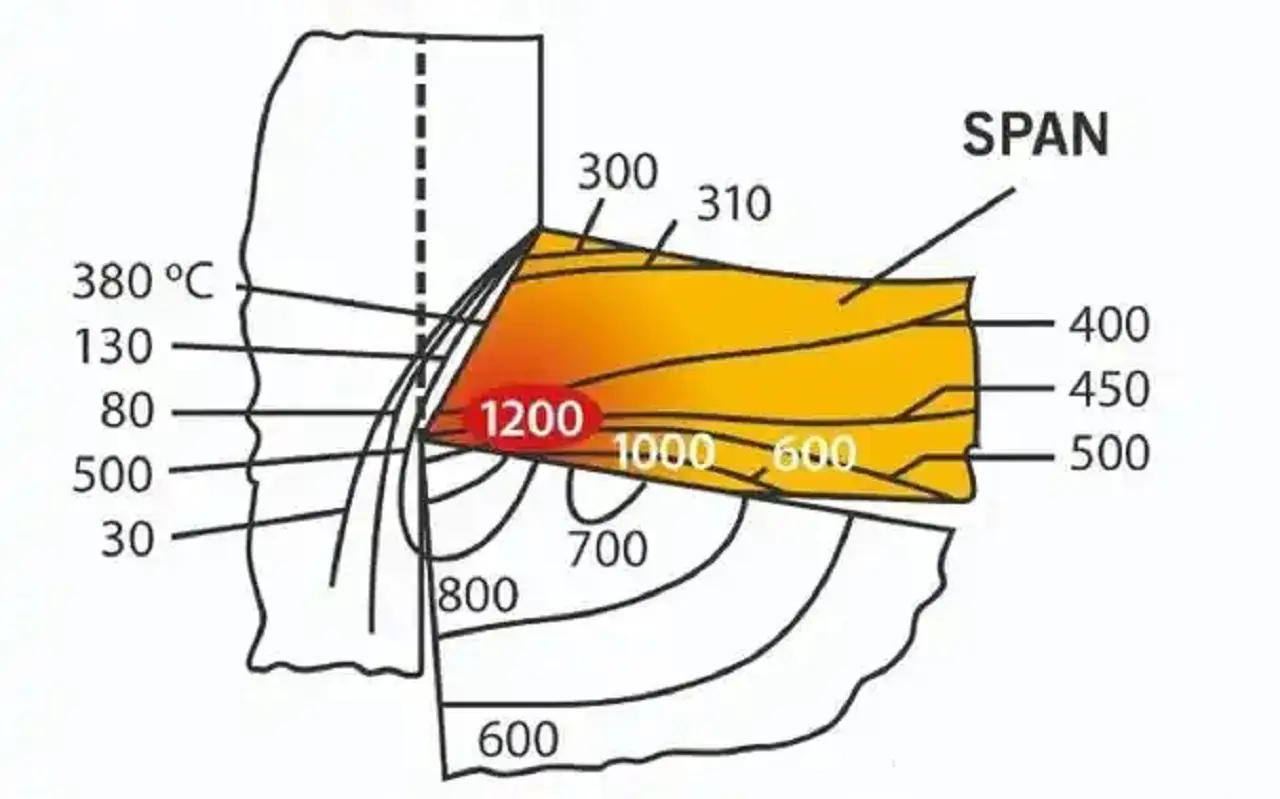

The thermal conductivity of titanium alloy is extremely low, only about 1/7 that of steel and 1/16 that of aluminum. Heat generated during cutting cannot be quickly transferred to the workpiece or carried away by the chips; instead, it concentrates in the cutting zone, causing temperatures to soar above 1000°C. This characteristic triggers a series of chain reactions:

- Rapid Tool Wear: High temperatures cause rapid wear and chipping of the tool edge, leading to built-up edge (BUE) formation. When the BUE detaches, it can take the carbide coating with it, accelerating wear further. For instance, titanium molecules from the workpiece accumulate in front of the insert and, under high pressure and temperature, "weld" onto the cutting edge to form a BUE, which damages the tool surface directly upon detachment.

- Degradation of Part Surface Quality: High temperatures compromise the surface integrity of the part, leading to reduced geometric accuracy and inducing work hardening, which severely diminishes the part's fatigue strength.

- Vicious Cycle of Thermal Friction: Cutting pressure causes the elastic workpiece to spring back after leaving the tool, enhancing friction and generating more heat, which further exacerbates the poor thermal conductivity issue.

2. Elastic Deformation: Vibration and Work Hardening Increase Difficulty

While the elasticity of titanium alloy is beneficial for part performance, it becomes a primary cause of vibration during the cutting process:

- Vibration Generation Mechanism: Cutting pressure causes elastic deformation of the workpiece. Its subsequent spring-back after leaving the tool results in friction between the tool and workpiece outweighing the cutting action. The heat generated by friction further intensifies thermal effects, creating a vicious cycle.

- Challenges in Thin-Wall Part Machining: When machining thin-walled or annular parts, localized deformation of the material as it is pushed aside by the tool may exceed the elastic limit, causing plastic deformation. This significantly increases the strength and hardness of the material at the cutting point. The originally set cutting speed then becomes too high, leading to rapid tool wear. For example, machining titanium alloy thin-walled parts requires precise control of cutting parameters; otherwise, dimensional accuracy is difficult to guarantee.

3. Work Hardening: Changes in Material Properties Increase Cutting Resistance

Titanium alloy is prone to work hardening during the cutting process, manifesting as:

- Increased Surface Hardness: Rising temperatures in the cutting zone increase the hardness of the material's surface layer, subsequently increasing cutting forces and accelerating tool wear.

- Limitations on Process Parameters: The hardened material becomes more difficult to machine. While heat treatment can enhance strength, it further increases insert wear. Therefore, it is crucial to machine titanium alloy in its softest possible state to avoid deterioration of material properties after hardening.

4. High Demands for Tool and Process Compatibility

To address the machining characteristics of titanium alloy, optimization is required in three aspects: tool material, geometry, and process parameters:

- Tool Material Selection: Special coatings or carbide materials are necessary to resist chemical reactions and diffusion at high temperatures. For example, inserts for titanium alloy machining need anti-groove wear capability to prevent localized wear caused by hardened layers left from previous operations.

- Geometric Design: Positive rake angle inserts can reduce cutting force, heat, and workpiece deformation. A large nose radius or chamfered entry helps distribute cutting forces and prevent localized damage.

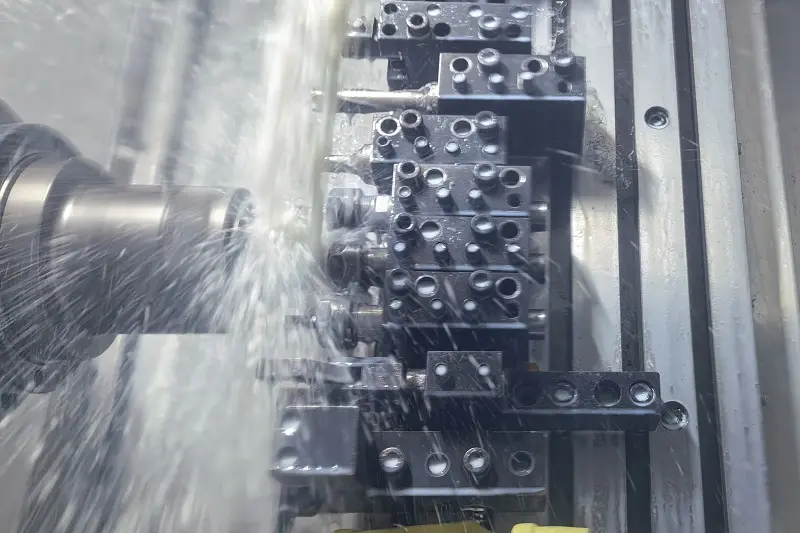

- Process Parameter Control: Maintain a constant feed rate to avoid workpiece hardening. In CNC milling, the radial depth of cut should be about 30% of the tool radius. Use high-pressure, high-volume coolant to ensure thermal stability and prevent surface alteration of the workpiece. Keep the cutting edge sharp, as a dull tool easily leads to heat buildup and wear.

5. Typical Machining Problems and Solutions

- Insert Groove Wear: Localized wear along the depth of cut direction, caused by hardened layers or high-temperature chemical reactions. Optimize tool material and geometry to minimize the impact of work hardening from previous operations.

- Built-Up Edge (BUE) Formation: Titanium molecules "weld" onto the cutting edge under high temperature and pressure, damaging the tool upon detachment. Solutions include controlling cutting temperature or using anti-adhesion coatings.

- Cutting Parameter Optimization: In milling, cutting speed has the greatest impact on tool life, followed by radial depth of cut. Parameters must be adjusted based on material condition and tool performance.

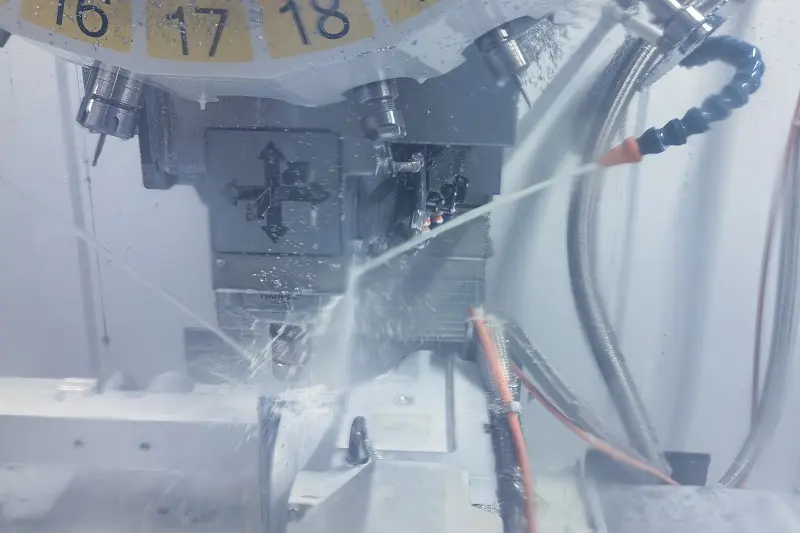

The difficult-to-machine nature of titanium

alloys stems from their low thermal conductivity, high chemical reactivity, and

significant elastic deformation. To enhance machining efficiency, it is

essential to synergistically optimize multiple aspects, including tool

material, geometric parameters, cutting strategies, and cooling methods. With

the application of new technologies such as cryogenic cooling,

vibration-assisted machining, and intelligent adaptive control, titanium alloy

machining is becoming more efficient and cost-effective. Looking ahead, the

rise of near-net-shape technologies like additive manufacturing (3D printing)

may lead to significant transformations in titanium alloy processing. However,

at the current stage, the continuous optimization of traditional cutting

processes, such as CNC turning and CNC milling, remains a critical focus in the

manufacturing industry.