+86 180 0293 5268

+86 180 0293 5268

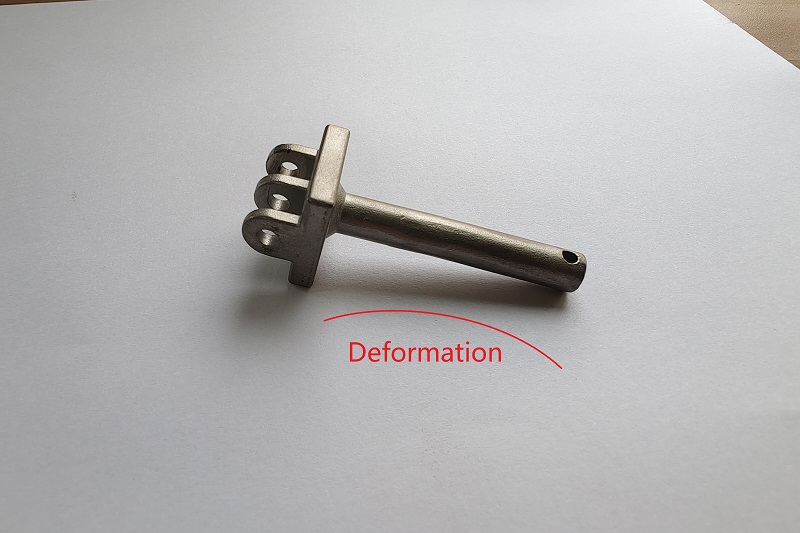

Why do some investment castings require dimensional correction?

Some custom investment castings are prone to deformation during production due to factors such as wax pattern distortion, structural design issues, mold shell warping after pouring, improper handling by workers during sand cleaning and shell shaking, heat treatment effects, or welding distortions during wax pattern assembly. These issues can lead to dimensional deviations or shape alterations, necessitating subsequent corrective measures. Correction is typically performed by applying external force, either at room temperature or elevated temperatures, and common methods include free correction, die correction, cold correction, and hot correction.

-

1. free correction & die correction

Free correction involves placing the metal casting on a flat plate or a simple dedicated jig and hammering it until the dimensions and shape meet the required specifications. This method is commonly used for small to medium-sized castings, while larger castings are typically corrected on specialized correcting equipment. Before correction, the deformation patterns of the casting should be understood, and suitable correction dies matching the geometric shape and dimensions of the casting must be prepared. Die correction, on the other hand, involves placing the casting into a correction die and applying selected pressure using a designated correcting machine for overall adjustment. During this process, lifting equipment or robotic arms are generally used to load and unload the casting from the die. Specifically designed and manufactured for particular castings, these correction dies demand high precision, making them ideal for mass production due to their efficiency and superior correction results. However, each product requires a custom correction die, which can be a limitation.

2. cold correction & hot correction

Cold correction involves correcting castings at room temperature using methods such as hammering, manual presses, jacks, friction presses, or hydraulic presses. This technique is suitable for small to medium-sized thin-walled castings with simple geometries and minor deformations, as well as for cast aluminum alloy components that exhibit significant deformation but good plasticity, or heavily deformed quenched aluminum castings. For castings with complex structures, straightening dies may be employed to assist the process.

Hot correction can be performed through either localized or full heating. When cold correction proves difficult for certain stainless steel castings, localized heating followed by hammering or press straightening may be used. For thick-walled, large castings requiring precision, full heating correction is recommended. Prior to correction, the deformation extent is measured, and the casting is then placed on support blocks inside a heat treatment furnace. Appropriate counterweights are applied to the areas needing correction, allowing the deformation to be rectified during the heat treatment process under controlled loading.

Dimensional correction, as a crucial process for rectifying external defects in castings, significantly impacts both the microstructure and mechanical properties of the components. Improper correcting techniques may introduce new or even more severe defects such as compression marks or cracks, necessitating strict process control. In foundry production, the appropriate correcting method must be carefully selected after comprehensive consideration of material properties and structural characteristics to prevent quality issues and avoid generating additional defects during the correction process.