+86 180 0293 5268

+86 180 0293 5268

Why is CNC machining widely used for so many components?

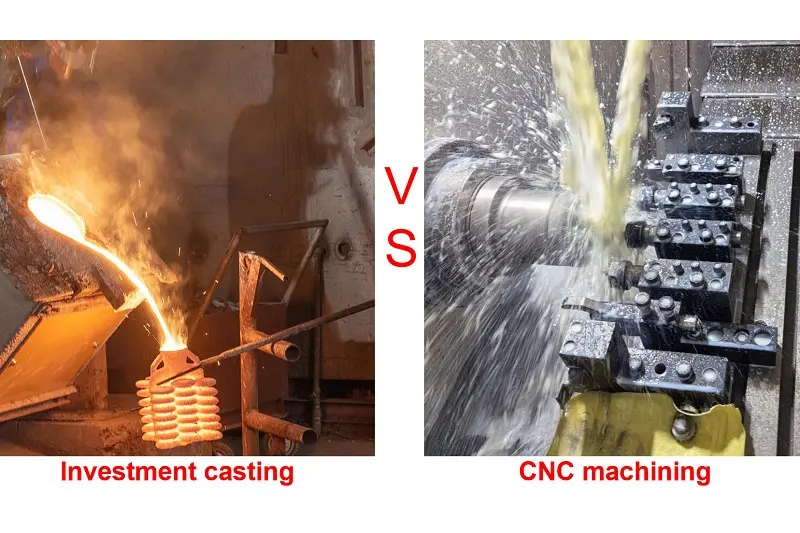

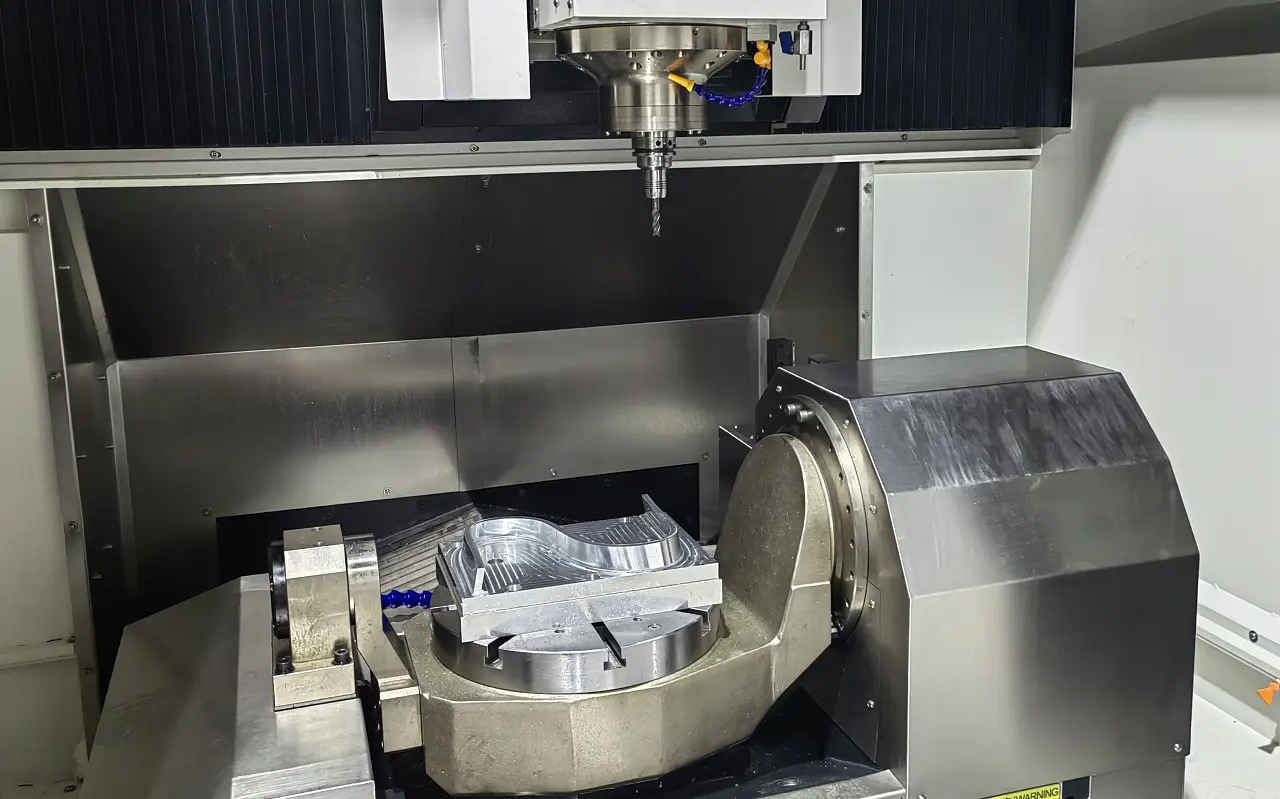

In modern manufacturing, CNC machining is supplanting traditional processes at an unprecedented rate, establishing itself as the gold standard for precision component production. Renowned for its superior precision, efficiency, and dependability, precision CNC machining has become the technology of choice for a multitude of industries. From aerospace and automotive manufacturing to electronics, medical equipment, and marine engineering, it delivers unparalleled benefits. This analysis will deconstruct the rationale behind this phenomenon across multiple dimensions—including efficiency, accuracy, and flexibility—to illuminate how CNC machining is fundamentally shaping industrial production.

-

1. Ultra-Precision and Unmatched Consistency

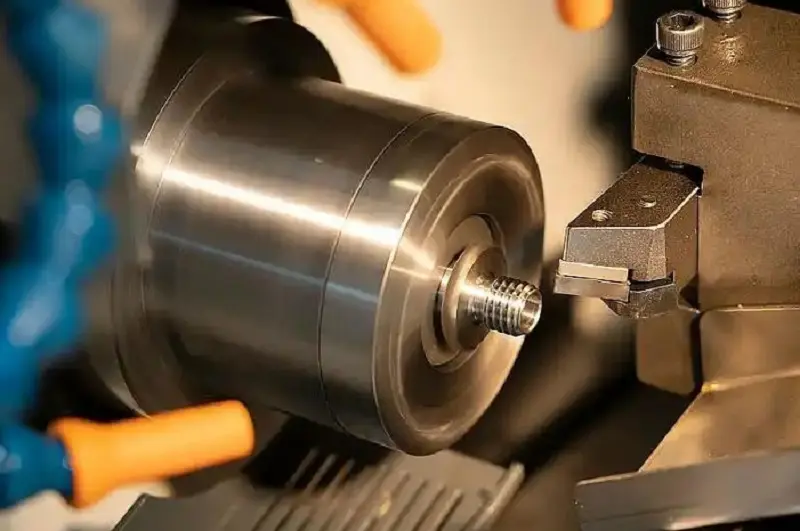

Traditional manual operations or conventional machine tools struggle to guarantee the dimensional stability of complex geometries. In contrast, precision CNC machining, which utilizes computer numerical control technology, achieves millimeter-to-even micron-level accuracy. Guided by pre-programmed instructions, the machine tools automatically execute intricate operations such as cutting, milling, and drilling, ensuring every part adheres to stringent design specifications.

This high level of precision not only minimizes human error but also ensures exceptional product consistency and reliability, making it particularly suitable for applications with extreme dimensional demands. For instance, aerospace engine blades, which require exceptionally smooth curved surfaces, can be manufactured via CNC machining with tolerances controlled within ±0.01mm. This near-perfect repeatability directly answers the question, "Why are so many components manufactured using CNC machining?" — it effectively eliminates the variations inherent in manual operations, making it ideally suited for the high-volume production of standardized components.

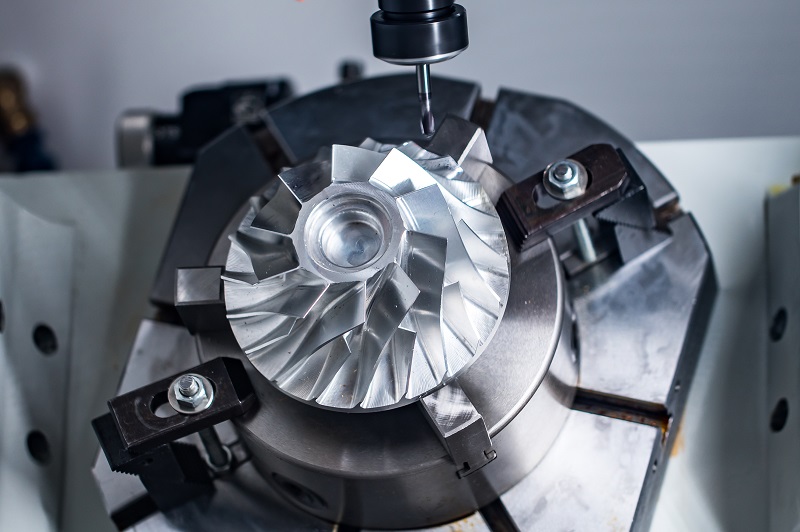

2. Efficient Production of Complex Structures

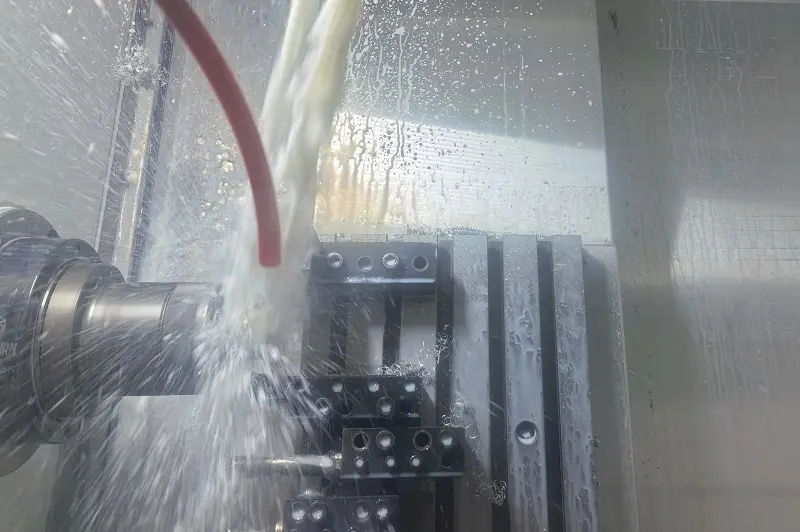

When designs involve complex 3D contours, irregular-shaped holes/slots, or intersecting threads, conventional machining processes often require multiple fixture adjustments and setups to complete the task. This approach is not only time-consuming but also prone to errors. In contrast, once the program is set up, a CNC machine can operate continuously without frequent adjustments or interruptions. The CNC system automatically interprets the complex toolpaths from the CAD model and, leveraging multi-axis capabilities (such as 4-axis or 5-axis simultaneous machining), can complete all operations—from milling to drilling—in a single setup. This allows multiple surfaces of a workpiece to be processed in one clamping, significantly boosting productivity.

For example, in the medical device industry, orthopedic implants featuring biomimetic trabecular structures must perfectly match a patient's unique anatomy. Only CNC machining can accurately reproduce such biomechanically optimized geometries. For batch production, CNC technology enables the rapid manufacturing of large quantities of parts, dramatically improving overall efficiency.

3. Wide Material Compatibility

Precision CNC machining is compatible with a wide range of materials, including metals (such as aluminum, steel, and titanium alloys), plastics (from standard to engineering grades), and composite materials. The CNC tool magazine can be quickly switched to adapt to the characteristics of different materials, while the machine itself adjusts processing parameters based on material properties to ensure optimal results. This flexibility enables CNC technology to meet the diverse needs of various industries, supporting high-quality production across applications — from industrial components to everyday consumer goods.

4. Automation and Smart Upgrades Driving Industry Transformation

Driven by technological advancements, the intelligent CNC machining process is now entirely governed by computer programs, which significantly reduces the need for manual intervention while lowering operational complexity and labor intensity. Modern CNC equipment, integrated with IoT sensors and AI algorithms, enables real-time monitoring and automatic correction functions. This allows for the detection and rectification of deviations during the machining process, ensuring consistent product quality. Such adaptive capabilities endow production lines with self-optimization abilities. Furthermore, alongside the evolution of smart manufacturing, CNC technology is increasingly converging with advanced technologies such as the Internet of Things and big data, thereby accelerating the transition of the manufacturing sector towards digitalization and intellectualization.

5. Outstanding Economic Value

Although the initial investment for CNC equipment is relatively high, its long-term economic benefits are substantial. High-precision machining minimizes material waste, automated operation reduces labor costs, and high production efficiency accelerates return on investment. Furthermore, components produced through CNC machining typically require no secondary processing, which additionally saves time and post-processing costs. For parts with high-precision requirements and for enterprises pursuing optimal cost-effectiveness, precision CNC machining is undoubtedly the superior choice.

In summary, precision CNC machining has become the cornerstone of modern manufacturing due to its combined advantages in accuracy, efficiency, material compatibility, cost-effectiveness, and automation. As smart manufacturing technology continues to evolve, this trend will undoubtedly extend into more specialized sectors, injecting new momentum into high-end assembly manufacturing, enhancing corporate competitiveness, and driving industry innovation.

Choosing precision CNC machining means opting for a reliable, efficient, and future-oriented production method. For enterprises seeking to upgrade their processes, understanding automated and intelligent CNC machining is key to securing a competitive edge. Far from becoming obsolete, precision CNC machining is growing increasingly indispensable to manufacturing, with a rising number of components across various industries being produced using this technology.