+86 180 0293 5268

+86 180 0293 5268

Non-standard CNC Machining Services for Outdoor Product Parts

Characteristic

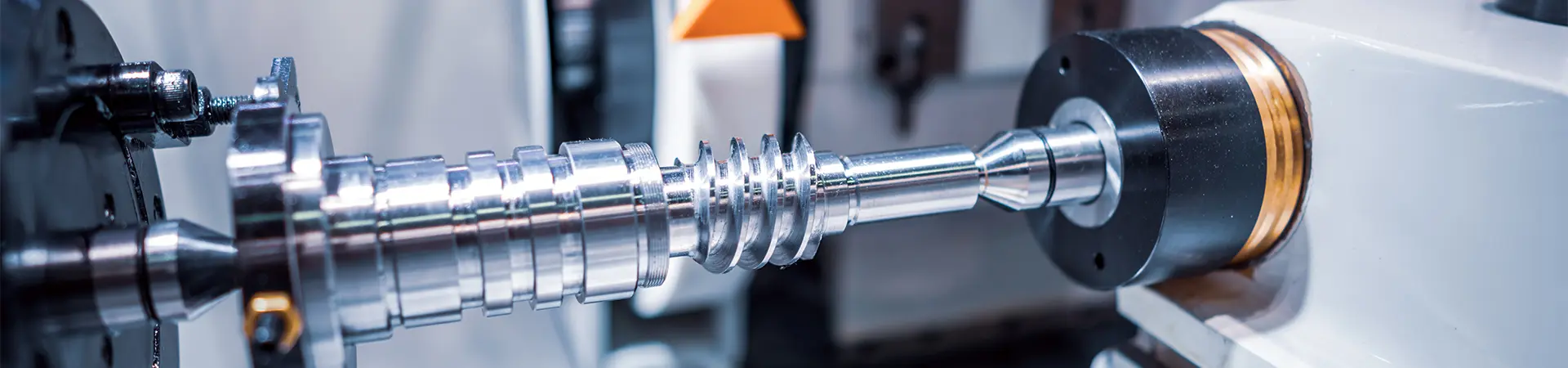

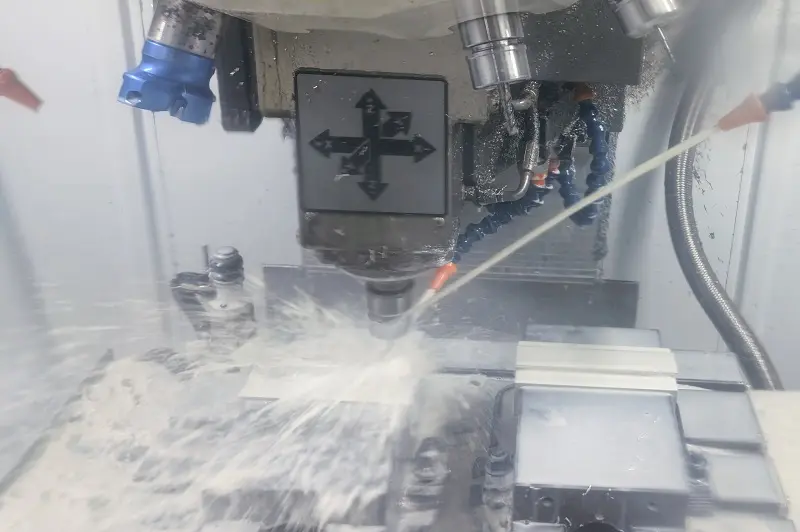

Aluminum alloy is widely used across various industries due to its excellent mechanical properties, superior thermal and electrical conductivity, good corrosion resistance, and light weight. CNC machining is highly common and accounts for a significant proportion of aluminum alloy part manufacturing. Thanks to aluminum alloy’s relatively low cutting resistance and reduced tool wear, machining can be performed at higher speeds, shortening production cycles and decreasing the frequency of tool replacements. With over ten years of experience in CNC turning, milling, and turn-milling composite machining of aluminum alloys, we maintain strict standards for precision and surface finish, ensuring both quality and efficiency in every project.

CNC-machined aluminum alloy parts have established a central role in modern manufacturing systems due to five key advantages: precision control, lightweight design, production efficiency, capability to handle complex structures, and adaptability to surface treatments. After CNC machining, the surface of aluminum alloy workpieces is smooth and uniform, providing an ideal substrate for subsequent finishing processes such as anodizing, sandblasting, or electroplating. This compatibility not only enhances the aesthetic quality of the product but also extends the service life of components through surface reinforcement. We have extensive expertise in aluminum alloy machining and surface treatment properties, enabling us to produce high-quality CNC-machined aluminum parts quickly and efficiently. We are your ideal partner for delivering superior results.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

We offer professional CNC machining services for a wide range of materials. Our CNC parts are exported worldwide, and we uphold stringent standards for both quality and efficiency. We are confident in being your ideal partner.

description2