+86 180 0293 5268

+86 180 0293 5268

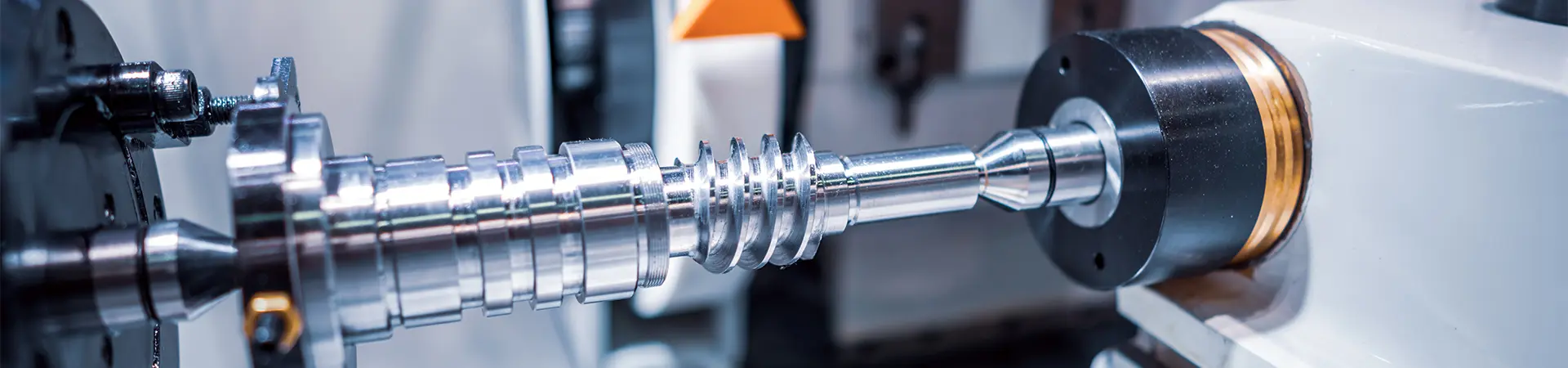

Non-standard CNC turning & CNC milling titanium alloy parts

Characteristic

Titanium alloy is a lightweight, high-strength metallic material renowned for its exceptional strength-to-weight ratio, low density, outstanding corrosion resistance, and excellent biocompatibility. Titanium alloy components are widely used across various industries, and their adoption continues to grow. However, the material itself is costly, and the machining process is challenging and expensive, leading to relatively high overall costs for titanium alloy parts. As a result, some industries opt to replace titanium alloy components with stainless steel or other more affordable alternatives to reduce the total cost of a project or product.

Titanium alloy materials offer exceptional specific strength, lightweight properties, outstanding corrosion resistance, excellent biocompatibility, as well as good thermal stability and non-magnetic characteristics. As a result, titanium alloy components are widely used in harsh environments or applications with demanding performance requirements. These parts can be manufactured through various processing techniques. Our company possesses extensive expertise in CNC turning, CNC milling, and CNC turn-mill compound machining. Leveraging our long-term accumulated experience, we can rapidly and accurately produce titanium alloy parts that meet specifications. This efficiency advantage enables us to significantly reduce the overall cost of titanium alloy components.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

With over a decade of experience in machining titanium bolt, titanium alloy bracket, crankshaft, and various other CNC machining components, we specialize in manufacturing parts from a wide range of materials including titanium alloys, stainless steel, carbon steel, copper, and aluminum. Our products have been widely exported to Europe, the United States, and Southeast Asian countries.

description2