+86 180 0293 5268

+86 180 0293 5268

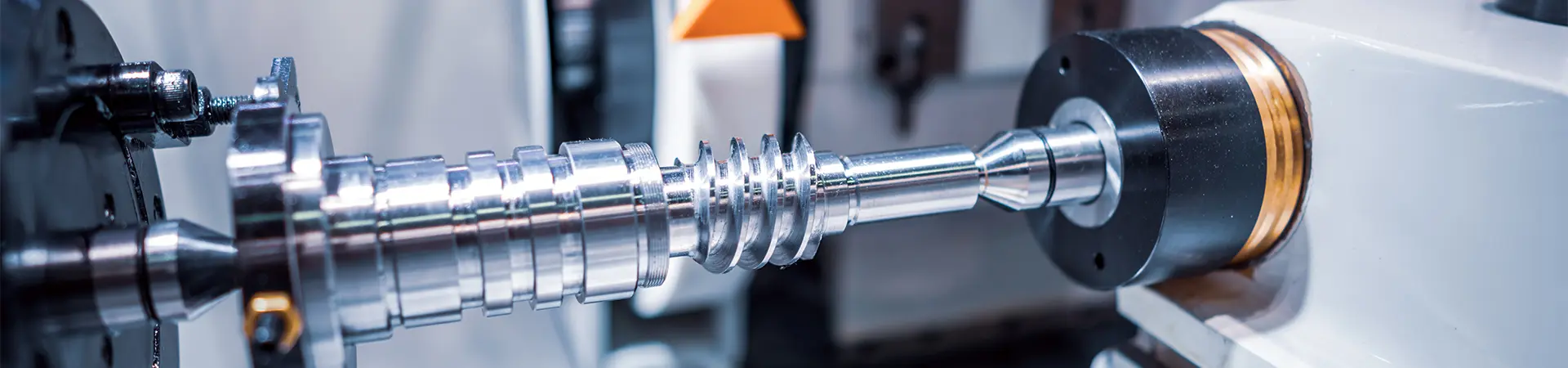

Non-Standard Part Processing Titanium CNC Service

Characteristic

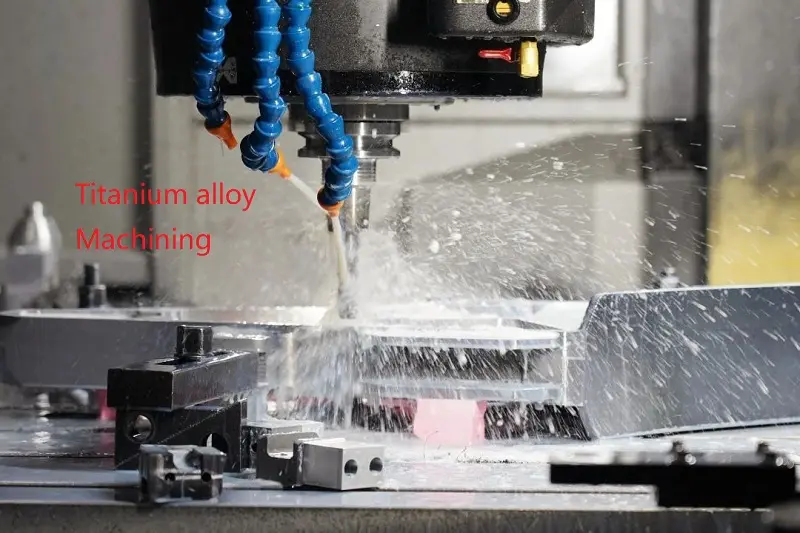

Titanium alloy is widely used in high-end manufacturing due to its high strength, corrosion resistance, and excellent mechanical properties. However, its machining poses significant challenges, primarily due to the material’s high chemical reactivity, low thermal conductivity, and high tool wear tendency, which often lead to reduced processing efficiency and increased costs. Compared to ordinary steel, CNC machining of titanium alloy requires attention in several key areas. First, milling cutters specifically designed for titanium must be used. Second, factors such as coolant selection, cutting parameters, and tool geometry need to be finely adjusted according to the characteristics of titanium alloy. By adhering to these considerations and adopting suitable machining strategies, both process stability and efficiency can be improved. Furthermore, through scientific process control, tool wear can be effectively minimized, machining quality enhanced, and efficient, reliable titanium CNC machining achieved.

While titanium alloy parts offer significant advantages in many aspects, their machining difficulty remains a key consideration. Therefore, when CNC machining titanium alloy, several critical points should be noted: First, due to its low elastic modulus—only about half that of ordinary steel—titanium alloy is more prone to deformation. It is advisable to use soft jaws with larger contact surfaces and reduce clamping force accordingly. Second, the low thermal conductivity of titanium alloy requires careful matching of cutting speeds based on the tool material used. Especially during micro‑cutting, particular attention should be paid to the risk of spontaneous combustion from heat buildup; it is recommended to use ample cutting fluid for cooling. Additionally, because titanium alloy exhibits significant elastic recovery during cutting, the tool’s relief angle should be designed larger—generally recommended to be greater than or equal to 15 degrees.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

We provide machining services for various titanium alloy components, including CNC turning, milling, and turn-mill compound processing. Our titanium alloy parts are widely used in industries such as marine, shipbuilding, aviation, medical, electronics, and smart wearables. We are committed to delivering high-quality products and on-time delivery to serve customers worldwide.

description2