+86-0769 81582278

+86-0769 81582278

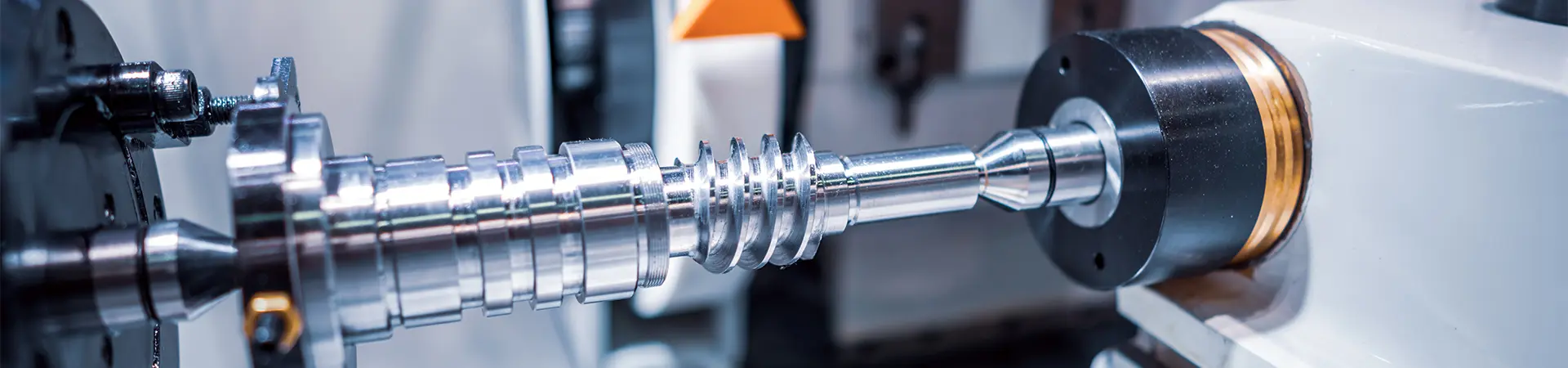

Precision Titanium CNC Machining Services for industry

Characteristic

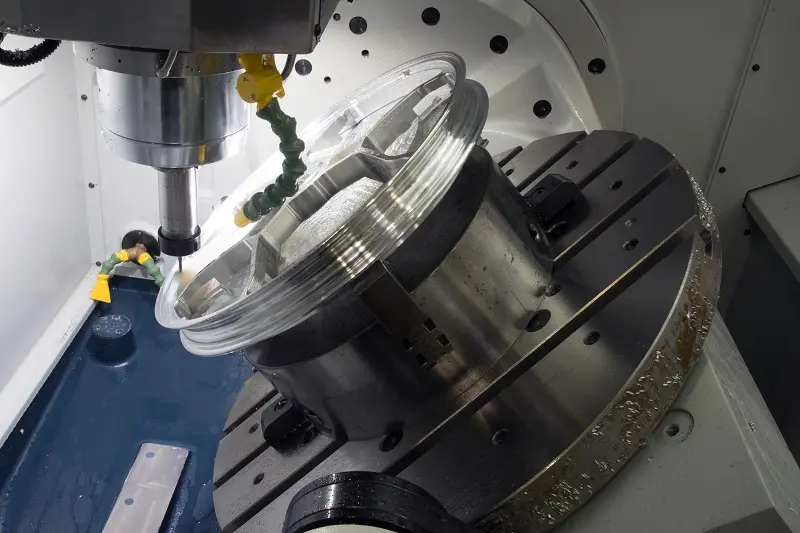

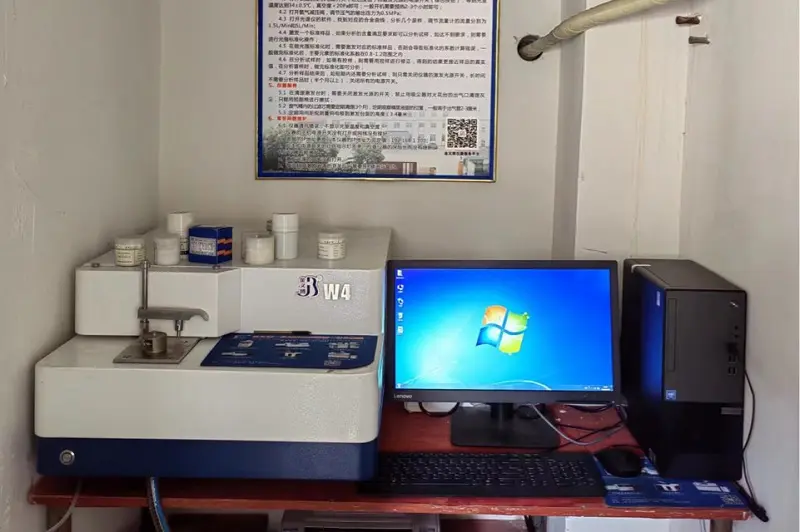

With extensive expertise in precision machining of titanium alloys, we specialize in manufacturing high-performance components for mission-critical applications across aerospace, medical, and automotive industries. Our advanced 5-axis CNC machines and specialized tooling overcome titanium's machining challenges - including its low thermal conductivity and work hardening tendencies - to produce complex aircraft structural parts, medical implants, and high-stress automotive components with exceptional accuracy (±0.01mm). Backed by full material traceability, CMM inspection, and spectroanalysis, we guarantee the material integrity and fatigue resistance required for these demanding applications. Our streamlined production process and experienced engineering team ensure reliable on-time delivery, making us the trusted partner for OEMs who cannot compromise on precision, quality, or delivery schedules in their titanium components.

Titanium CNC parts are widely used in aerospace (engine mounts, landing gear), medical (implants, surgical tools), and high-performance automotive (valves, connecting rods) due to their strength, lightweight, and corrosion resistance. However, machining titanium requires specialized expertise—its low thermal conductivity and high chemical reactivity demand rigid CNC machines, ceramic-coated tools, and optimized cooling. Our advanced 5-axis CNC systems and strict process controls ensure tight tolerances (±0.01mm), superior surface finishes, and minimal material waste. With ISO-certified quality checks (CMM, spectroanalysis), we guarantee precision, durability, and on-time delivery for mission-critical applications where reliability is non-negotiable.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan Shixin Machinery Technology Co., Ltd

We specialize in precision titanium CNC machining, offering prototyping to mass production with ±0.01mm tolerance guarantee. All parts include full material certification and quality reports, backed by 98% on-time delivery and dedicated engineering support for your custom machining needs.

description2