+86 180 0293 5268

+86 180 0293 5268

Professional Investment Casting Factory Customizes Smart Home Casting Components

Characteristic

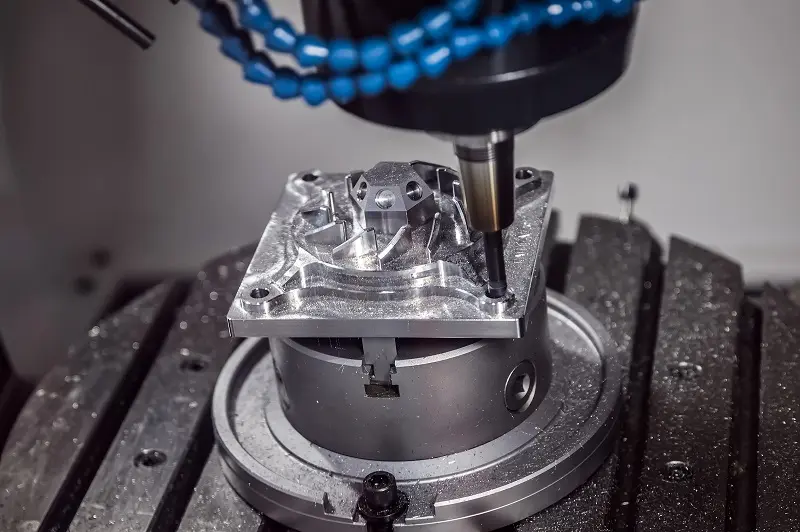

Among various metal parts, there are numerous processing techniques available, such as CNC machining, forging, investment casting, powder metallurgy, and more. So, how do we select the most suitable processing method? This requires a comprehensive consideration of factors such as the product material, operating environment, precision requirements, surface finish demands, and production volume. For example, forging is well-suited for parts that require high strength, relatively simple structures, and moderate precision. CNC machining, on the other hand, excels in achieving extremely high precision and excellent surface quality, though it comes with higher processing costs. Metal investment casting, meanwhile, is capable of producing parts with complex structures, high precision, and good surface finish, making it suitable for both small and large batch production. Please share your part details with me, and I will assist you in analyzing which processing method is best suited for your specific needs.

Investment casting is a complex process, and it typically requires coordination with subsequent treatments such as heat treatment, CNC machining, and various surface finishing techniques. To produce a high-quality investment casting, every step in the process must be meticulously aligned. Internally, we operate our own investment casting workshop, a precision CNC machining workshop (including CNC turning, CNC milling, and turn-milling combined machining), and we collaborate with external partners for heat treatment and surface finishing. Thanks to years of seamless coordination across these processes, we can ensure that the investment castings we deliver fully meet our customers' application requirements.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

We provide investment casting and CNC machining services for various metals, complemented by heat treatment and surface finishing processes, as well as basic assembly services. We take full responsibility for the products we manufacture and offer unconditional after-sales support.

description2