+86 180 0293 5268

+86 180 0293 5268

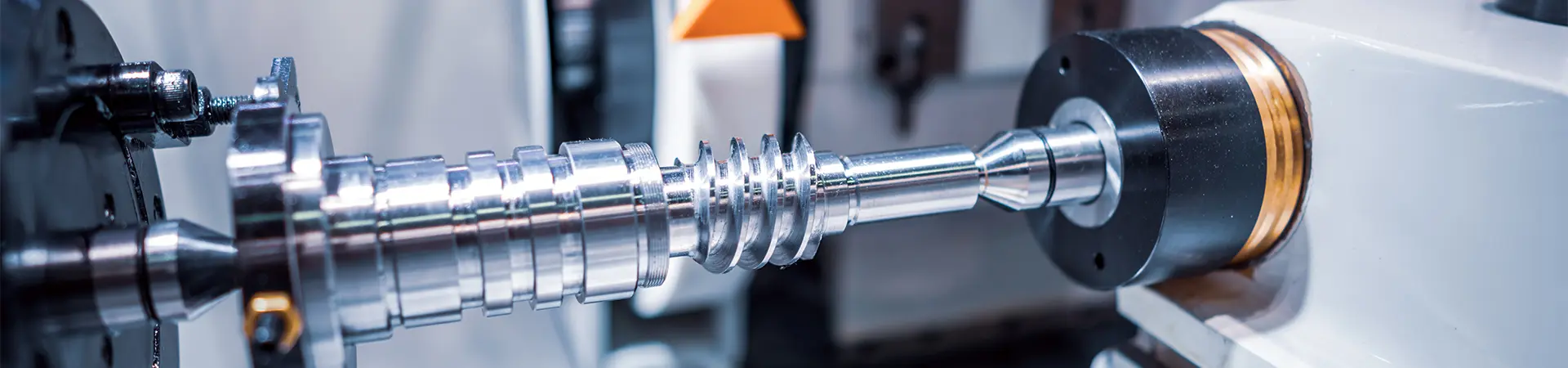

Providing CNC milling services for non-standard aluminum components

Characteristic

Aluminum is a lightweight metal known for its excellent corrosion resistance, electrical conductivity, and thermal conductivity, with a density only one-third that of steel. It also offers relatively good machinability, being easy to cut and form, making it well-suited for precision machining. In our precision CNC machining processes for aluminum products, we have extensive experience in selecting appropriate cutting tools and optimizing machining parameters. Based on the specific product requirements, we choose suitable tools to enhance wear resistance and service life. Furthermore, we rationally configure parameters such as cutting speed, feed rate, and depth of cut to improve both machining quality and efficiency.

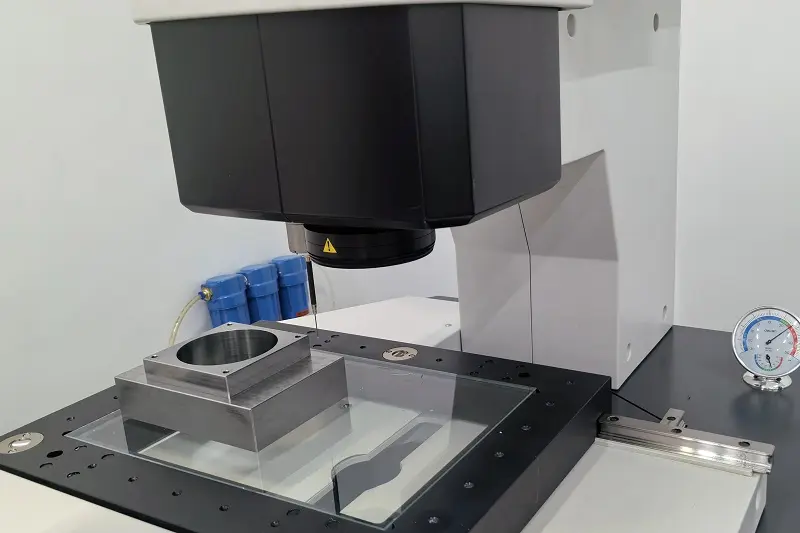

Aluminum CNC parts are widely used across various industries, including aerospace, automotive manufacturing, electronic devices, and marine engineering. Thanks to their lightweight nature and high strength, aluminum alloys are extensively employed in structural components such as bicycle frames. Additionally, due to their excellent thermal conductivity and corrosion resistance, they are commonly used in heat sinks and enclosures for electronic equipment. Naturally, quality control is critical for any CNC machining company. To ensure product quality, we perform multiple measurements and inspections throughout the machining process. When necessary, advanced equipment such as CMMs and optical measuring devices are utilized to verify that both appearance and dimensions meet specified requirements.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

We not only provide CNC machining services for aluminum parts, but also offer comprehensive post-processing operations, including sandblasting, polishing, wire drawing, anodizing, electroplating, spray coating, and more. Additionally, we deliver professional precision CNC machining services for a wide range of other materials, such as stainless steel, titanium alloys, and engineering plastics.

description2