+86 180 0293 5268

+86 180 0293 5268

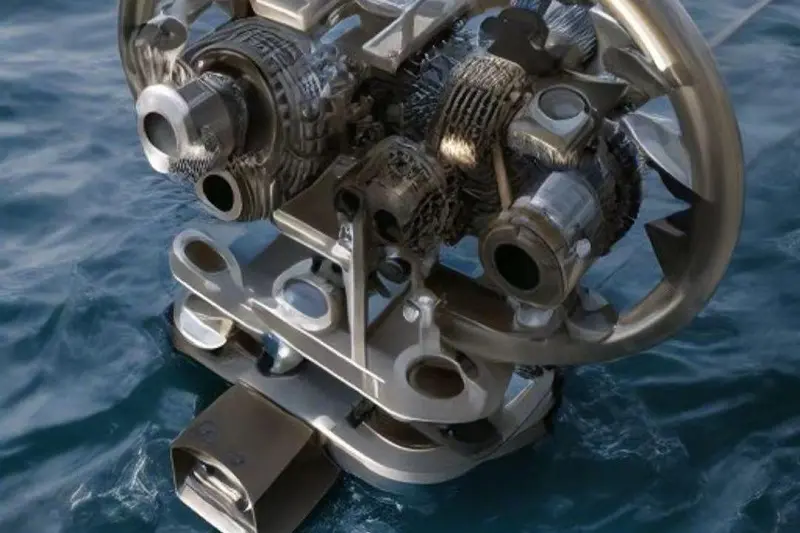

Stainless Steel Castings for Marine Engineering

Characteristic

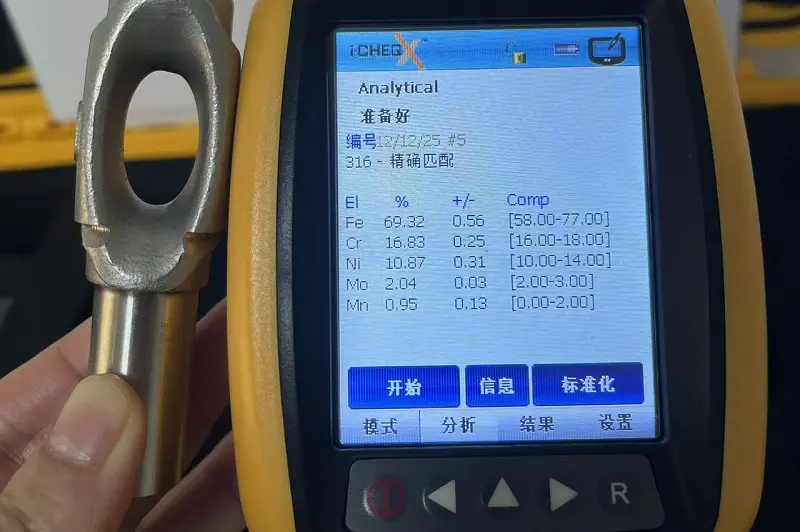

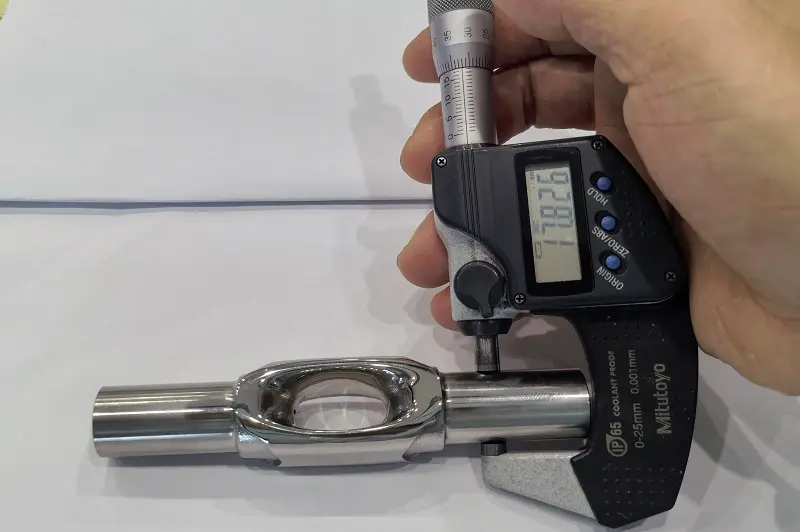

The operational environment in marine engineering is extremely demanding. Seawater is corrosive due to its salt content, which can lead to corrosion when in contact with metal objects, making it particularly aggressive in coastal areas. Therefore, metal components used in such applications must be made of highly chloride-resistant materials such as stainless steel 316. Stainless steel 316 parts can be manufactured through various processes, including CNC machining, forging, casting, stamping, and powder metallurgy. Among these, CNC machining and investment casting are the most suitable for producing structurally complex components. Between the two, investment casting offers a more cost-effective solution. Consequently, many marine engineering parts are produced via investment casting, as it combines excellent performance with economical production.

Services

Dongguan SX Technology Co.,Ltd

Contact usdescription2