+86 180 0293 5268

+86 180 0293 5268

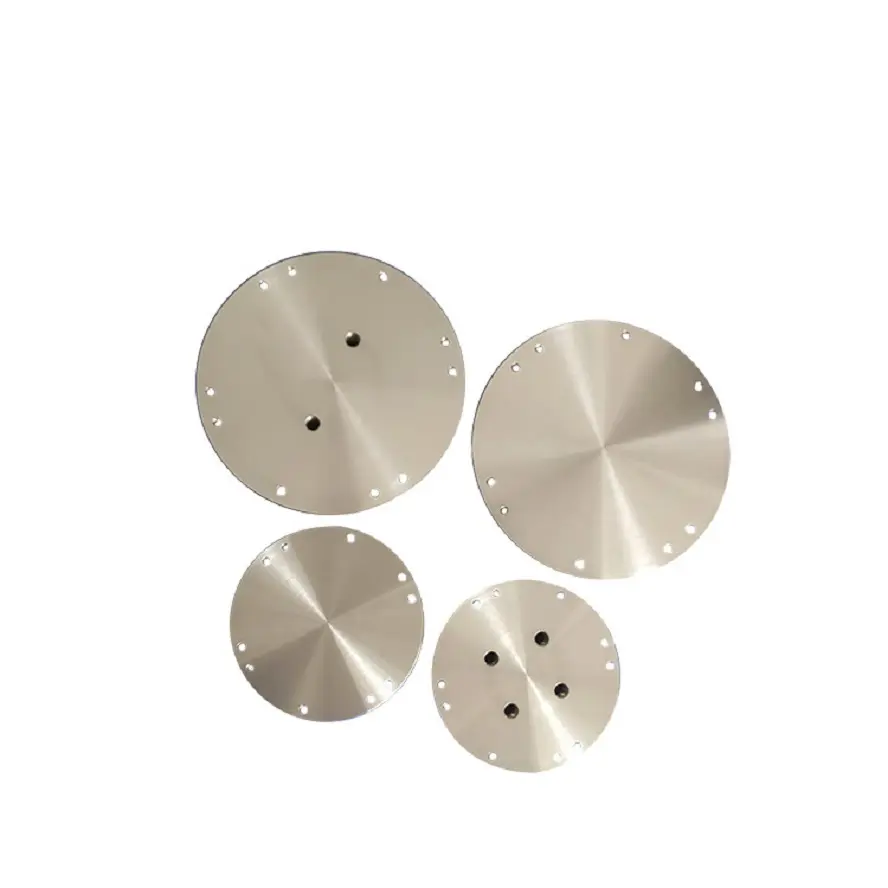

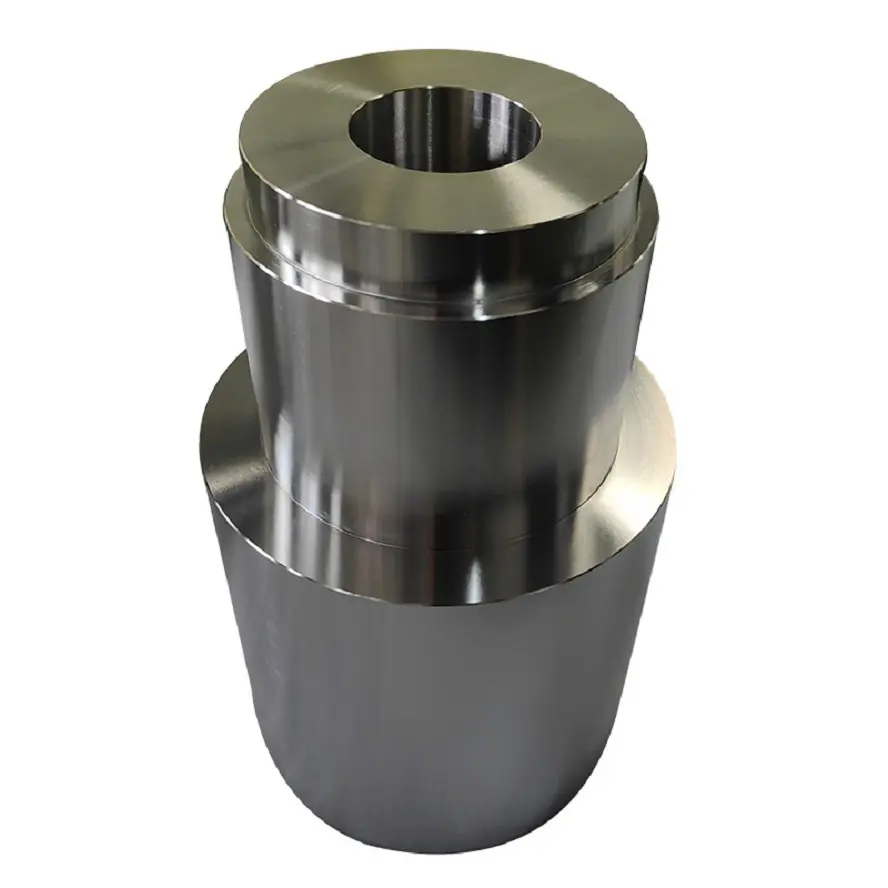

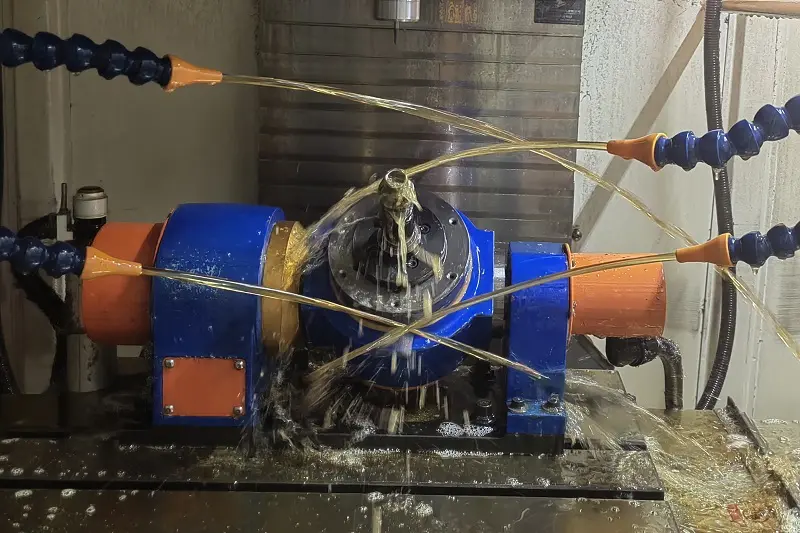

Titanium alloy parts for deep-sea equipment

Characteristic

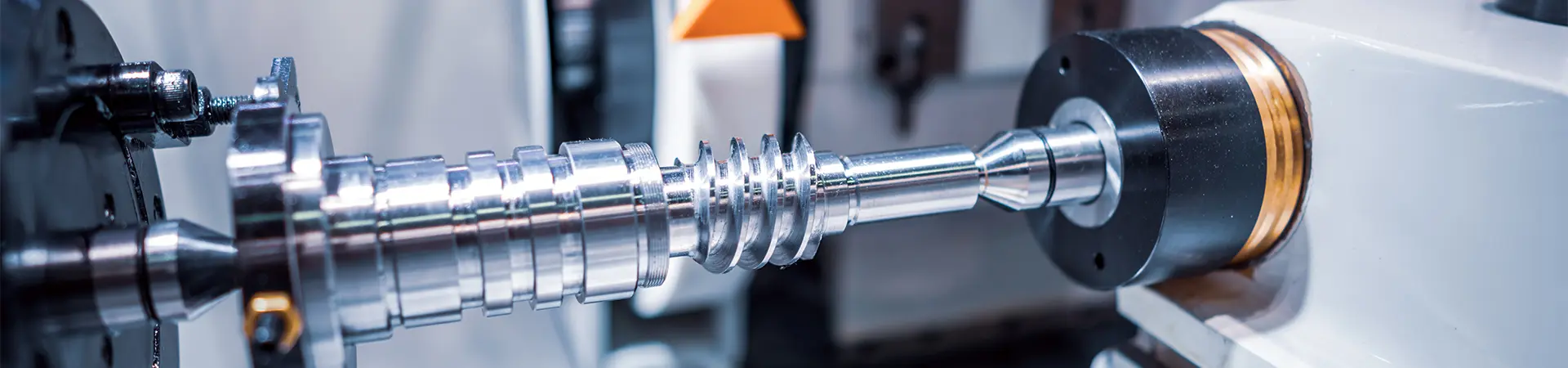

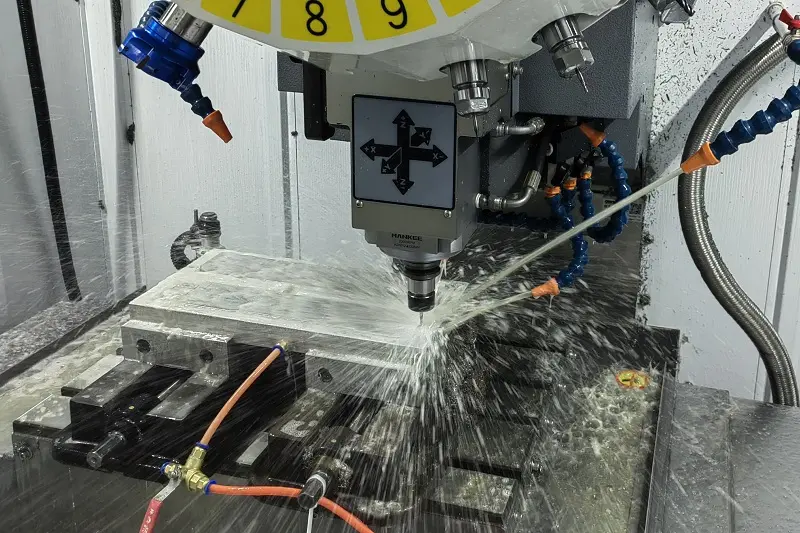

CNC machining stands as the optimal manufacturing process for titanium alloy parts, particularly for applications demanding high precision and superior performance. While titanium alloys like Ti-6Al-4V offer exceptional strength-to-weight ratios and corrosion resistance, their machining presents challenges such as high cutting forces and rapid tool wear. CNC technology overcomes these hurdles through computer-controlled precision, enabling efficient production of complex geometries with tight tolerances (±0.01mm) and superior surface finishes (Ra<0.8μm). Multi-axis machining capabilities allow for intricate features including deep cavities and thin-walled structures, while adaptive cutting parameter optimization extends tool life. The process ensures excellent repeatability for small-to-medium batch production, and when combined with post-processing treatments (e.g., sandblasting, anodizing), further enhances component performance. These advantages make CNC machining the preferred solution for critical titanium components in aerospace, medical implants, and deep-sea equipment applications.

Titanium alloy parts excel in strength-to-weight ratio, corrosion resistance, and high-temperature performance, ideal for aerospace, medical, and automotive industries. Their biocompatibility ensures safety in medical implants. CNC machining delivers precision, complex geometries, and superior surface finishes. Compared to steel, titanium is lighter yet equally strong, enhancing fuel efficiency and durability. Our expertise ensures tight tolerances, cost-effective production, and rapid prototyping. Trust our CNC solutions for high-performance, reliable titanium components tailored to your specs.

-

Design

-

Engineered

-

Manufactured

Services

Dongguan SX Technology Co.,Ltd

Precision-machined titanium parts with tight tolerances (±0.01mm), fast turnaround, competitive pricing, and expert engineering support. Custom solutions for aerospace, medical & automotive industries. Quality guaranteed.

description2